Clean high-temperature water-base fracturing fluid

A high-temperature water, clean technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as insufficient temperature resistance of clean fracturing fluids, achieve good sand suspension ability, reduce operating costs, and achieve high temperature resistance. The effect of boosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Add 908.5ml of water into a mixer with a capacity of 1500ml, slowly add 5g of xanthan gum under stirring, and stir at a high speed for 5min; then add 10g of potassium chloride, 10g of absolute ethanol, and 0.5g of glutaraldehyde solution g, 50 g of calcium chloride, 16 g of erucamide propyl hydroxysultaine, and stirring for 3 minutes to 5 minutes to obtain the water-based fracturing fluid of the present invention.

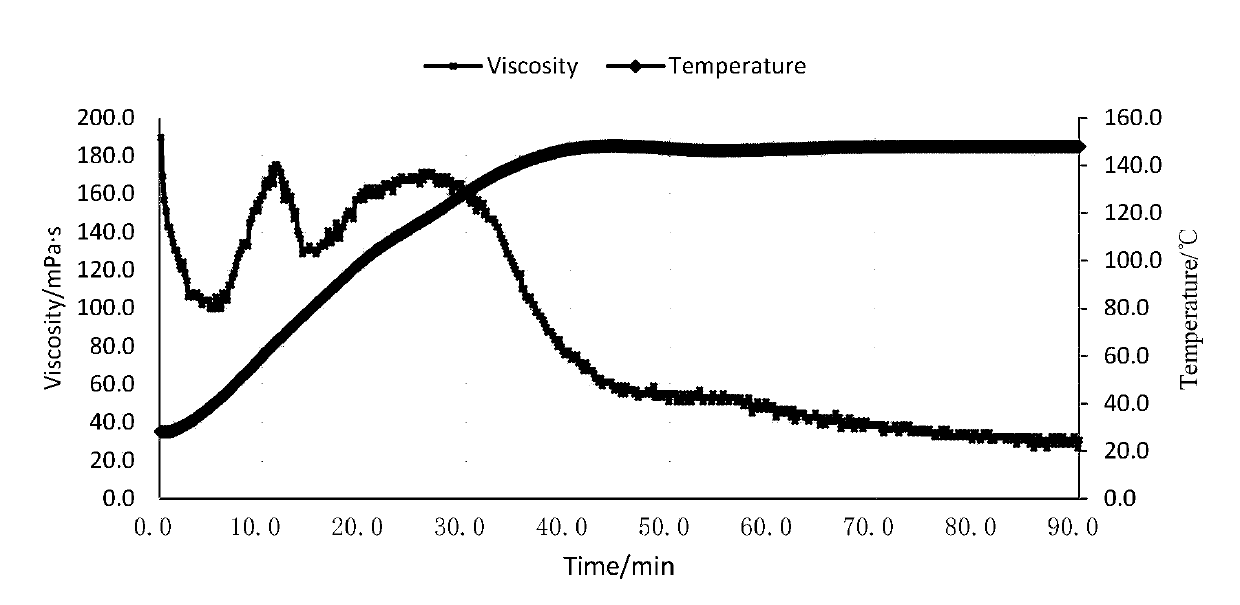

[0031] The viscosity-temperature performance of the fracturing fluid in this embodiment is tested, and the rheological performance of the sample is tested by a Brookfield PVS viscometer, and the shear rate is 170s -1 After shearing for 90min, the viscosity-temperature curve of Example 1 was obtained.

[0032] The viscosity-temperature performance of the fracturing fluid in this implementation case is tested, and the performance is as follows: the test temperature is 150°C, and the shear rate is 170s -1 , after 90 minutes, the viscosity remained s...

Embodiment 2

[0033]Example 2: Add 909.5ml of water into a mixer with a capacity of 1500ml, slowly add 5g of sodium carboxymethylcellulose under stirring, and stir at a high speed for 5min; then add 20g of potassium chloride solution, 9g of absolute ethanol, and Dialdehyde solution 0.5g, calcium chloride solution 50g, erucamide propyl hydroxysulfobetaine solution 6g, stirred for 3min-5min to obtain the water-based fracturing fluid of the present invention.

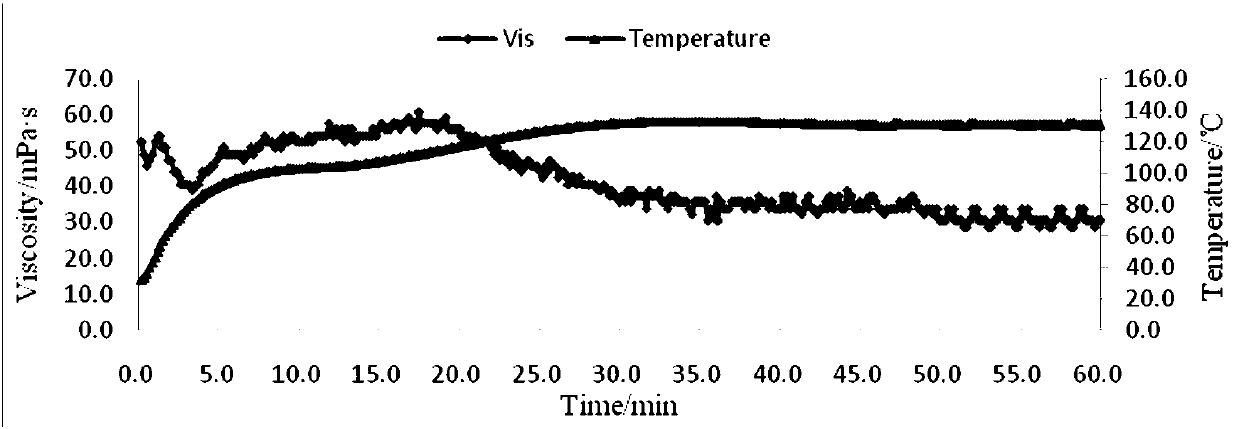

[0034] The rheological properties of the samples were tested by Brookfield PVS viscometer, the shear rate was 170s -1 After shearing for 60 min, the viscosity-temperature curve of Example 2 was obtained.

[0035] The viscosity-temperature performance of the fracturing fluid in this implementation case is tested, and the performance is as follows: the test temperature is 130°C, and the shear rate is 170s -1 , after one hour, the viscosity remained stable at 30.4mPa·s.

Embodiment 3

[0036] Example 3: Add 908.5ml of water into a mixer with a capacity of 1500ml, slowly add 5g of xanthan gum under stirring, and stir at a high speed for 5min; then add 20g of ammonium chloride solution, 10g of isopropanol, dodecyl 0.5g of trimethylammonium chloride, 50g of calcium chloride solution, 6g of betaine amidopropyl betaine, and stirring for 3min-5min, the water-based fracturing fluid of the present invention is obtained.

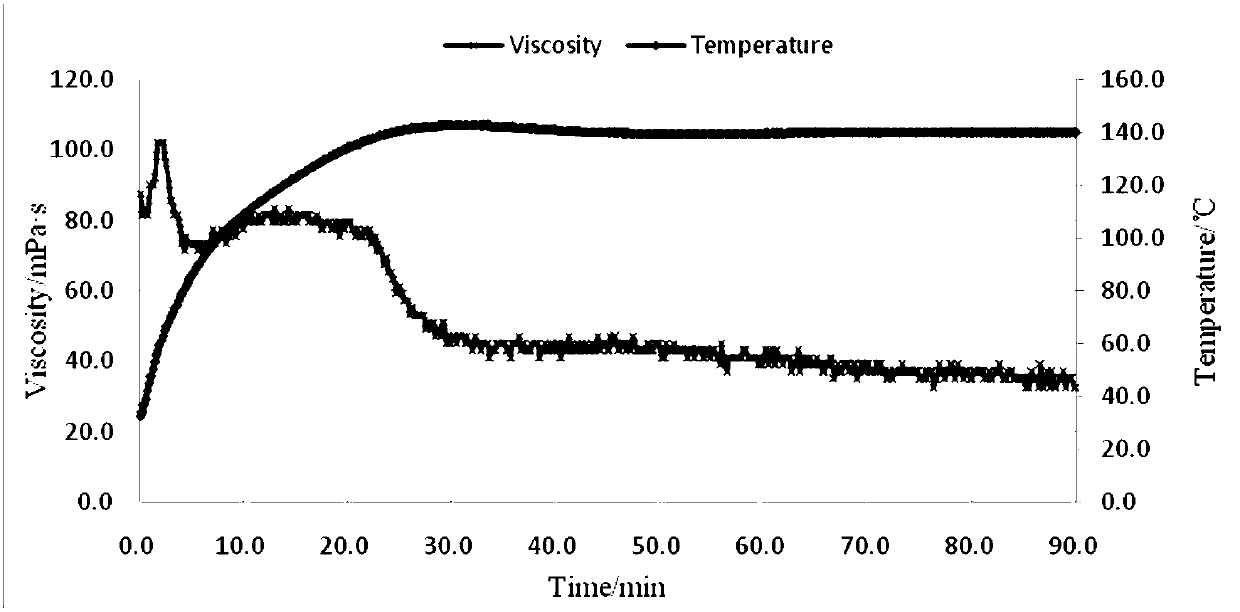

[0037] The rheological properties of the samples were tested by Brookfield PVS viscometer, the shear rate was 170s -1 After shearing 90min, obtain the viscosity-temperature curve of embodiment 3 image 3 .

[0038] The viscosity-temperature performance of the fracturing fluid in this implementation case is tested, and the performance is as follows: the test temperature is 140°C, and the shear rate is 170s -1 , After 90 minutes, the viscosity was stable at 32mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com