Cationic asphalt emulsifier, preparation method thereof and preparation method of asphalt emulsion

A technology of asphalt emulsifier and cationic etherification agent, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of iodine vapor being toxic and not having good application effects, and achieve increased adhesion and HLB Value Range, Effect of Time Dominance on Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of cationic asphalt emulsifier, comprising the following steps:

[0024] Add 30 parts of linoleic acid dimer acid into the reaction kettle, stir and heat up to 80°C, add 20 parts of polyethylene polyamine into the kettle, stir and raise the temperature to 150°C within half an hour, keep the temperature for 6-10 hours, until Until there is no distillate in the reaction, then lower the temperature to 60°C, slowly add 5 parts of cationic etherification agent dropwise, and control the temperature not to exceed 80°C, after the dropwise addition, keep the temperature at 70-80°C for 5 hours, and then cool to 50-60°C ℃, slowly add 10 parts of paraformaldehyde, control the temperature not to exceed 70 ℃, after the dropwise addition, keep warm at 70-80 ℃ for 4 hours, then cool to 50-60 ℃ and discharge to obtain cationic asphalt emulsifier.

[0025] Preparation of emulsified asphalt

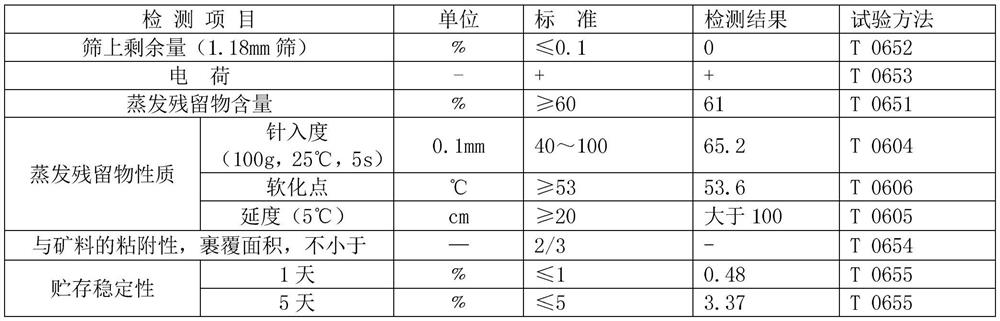

[0026] Take 10g of the asphalt emulsifier prepared above (accounting for 2....

Embodiment 2

[0034] A preparation method of cationic asphalt emulsifier, comprising the following steps:

[0035] Add 20 parts of palmitic acid dimer acid into the reaction kettle, stir and heat up to 80°C, add 10 parts of triethylenetetramine into the kettle, stir and raise the temperature to 150°C within half an hour, keep the temperature for 6 to 10 hours, until the reaction Until there is no distillate, then lower the temperature to 60°C, slowly add 25 parts of cationic etherification agent dropwise, control the temperature not to exceed 80°C, after the addition is completed, keep it at 70-80°C for 5 hours, then cool to 50-60°C , slowly add 10 parts of paraformaldehyde dropwise, and control the temperature not to exceed 70°C. After the dropwise addition, keep warm at 70-80°C for 4 hours, then cool to 50-60°C and discharge to obtain a cationic asphalt emulsifier.

[0036] Preparation of emulsified asphalt

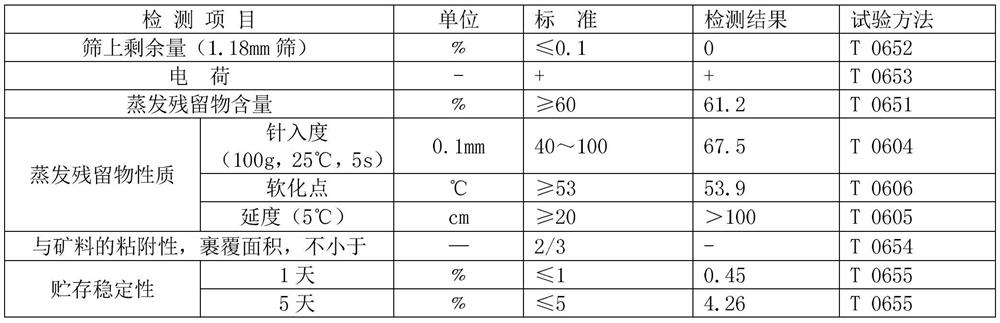

[0037] Take 11g of the asphalt emulsifier prepared above (accounting for 2.2% o...

Embodiment 3

[0045] A preparation method of cationic asphalt emulsifier, comprising the following steps:

[0046] Add 25 parts of dimer acid into the reaction kettle, stir and raise the temperature to 80°C, add 15 parts of tetraethylenepentamine to the kettle, stir and raise the temperature to 150°C within half an hour, keep the reaction for 6 to 10 hours, until the reaction has no distillation until the product is produced, then lower the temperature to 60°C, slowly add 13 parts of cationic etherification agent dropwise, and control the temperature not to exceed 80°C, after the dropwise addition, keep it at 70-80°C for 5 hours, then cool to 50-60°C, slowly Add 6 parts of paraformaldehyde dropwise, and control the temperature not to exceed 70°C. After the dropwise addition, keep the temperature at 70-80°C for 4 hours, then cool to 50-60°C and discharge to obtain a cationic asphalt emulsifier.

[0047] Preparation of emulsified asphalt

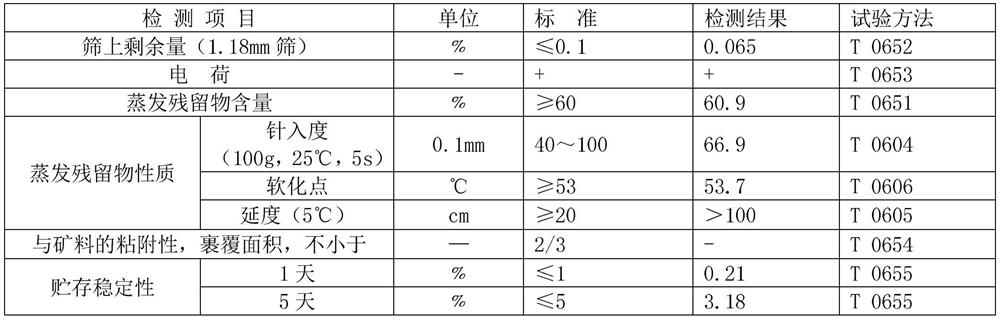

[0048] The preparation steps are the same as in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com