Endogenous frosting-effect glass ink and method for producing frosting-effect product by utilizing same

A frosting and ink technology, applied in the directions of ink, application, household appliances, etc., to achieve the effect of smooth and bright coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

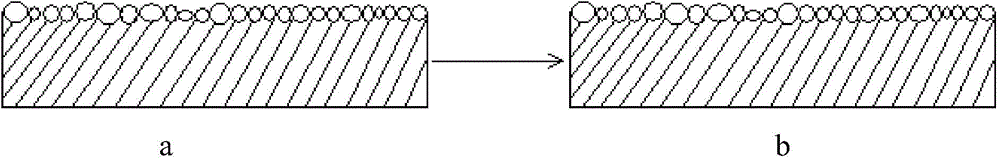

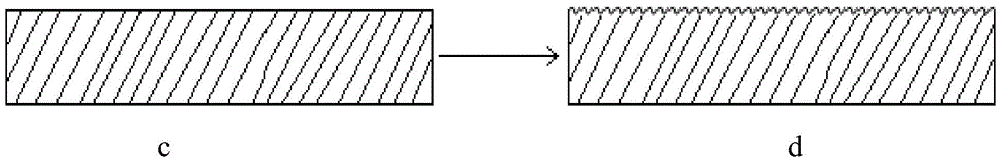

Method used

Image

Examples

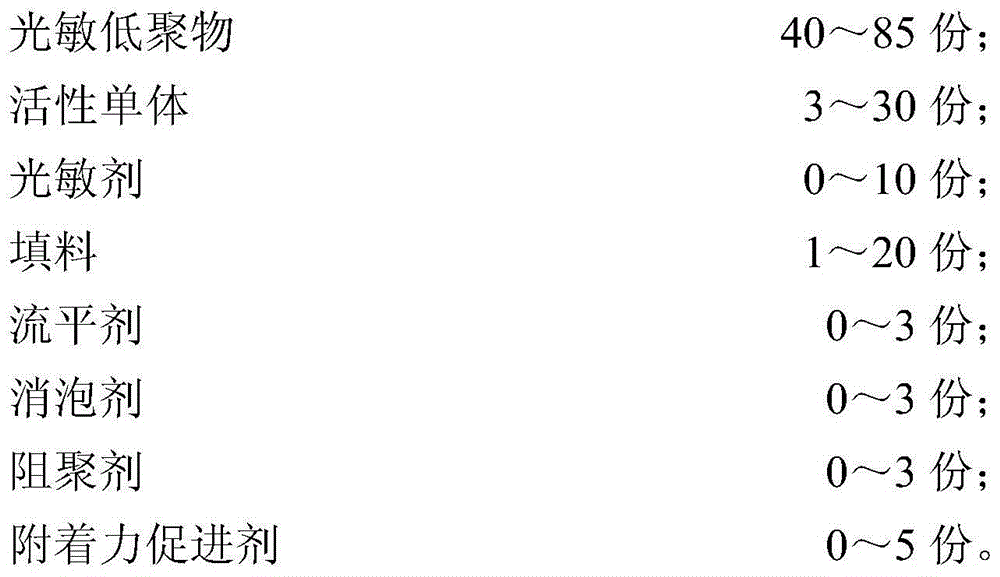

Embodiment 1

[0057] Polyurethane acrylate (US Sartomer CN9006) 57 parts, epoxy acrylate (Taiwan Changxing Chemical DR-G908) 17 parts, trimethylolpropane triacrylate (TMPTA) 8 parts, tripropylene glycol diacrylate (TPGDA) ) 5 parts, 3 parts of hydroxypropyl methacrylate (HPMA), 1 part of 1-hydroxycyclohexyl phenyl ketone (UV-184), 1 part of 4-phenylbenzophenone (PBZ), 5 parts of talcum powder 0.5 part of antifoaming agent (Germany BYK-1790), 0.5 part of polymerization inhibitor (p-hydroxyanisole), 2 parts of adhesion promoter (acid-modified acrylate, EB168 of American allnex chemical company) 1. Leveling agent (Germany BYK-354) 1 part, the above-mentioned components can be mixed to prepare the endogenous frosting effect ink.

[0058] Curing conditions: the first strength is 50mw / cm 2 irradiate the coating with UV light for 50 seconds, and then use 280mw / cm 2 High-energy UV light exposure for 3 seconds.

Embodiment 2

[0060] Aromatic acid half acrylate SB40015 parts, polyester acrylate 6336-10035 parts, amino acrylate 611715 parts, dipentaerythritol hexaacrylate (DPHA) 8 parts, neopentyl glycol diacrylate (NPGDA) 7 parts, methacrylic acid 6 parts of hydroxypropyl ester (HPMA), 0.5 part of 1-hydroxycyclohexyl benzophenone (184), 0.5 part of isopropyl thioxanthone (ITX), 9 parts of white carbon black, defoaming agent (German BYK chemical BYK-1790) 0.5 parts, polymerization inhibitor (p-hydroxyanisole) 0.5 parts, adhesion promoter (γ-aminotriethyloxysilane KH-550) 2 parts, leveling agent (German BYK chemical BYK -354) 1 part, the endogenous frosting effect ink can be prepared by mixing the above components.

[0061] Curing conditions: the first strength is 70mw / cm 2 irradiate the coating with UV light for 45 seconds, and then use 250mw / cm 2 High-energy UV light exposure for 5 seconds.

Embodiment 3

[0063] Polyurethane acrylate (CN968 of American Sartomer Company) 59 parts, polyester acrylate (Taiwan Changxing Chemical 6196) 9 parts, epoxy acrylate DR-G9085 parts, dipentaerythritol hexaacrylate (DPHA) 7 parts, tripropylene glycol di Acrylate (TPGDA) 5 parts, hydroxypropyl methacrylate (HPMA) 2 parts, benzophenone (BP) 2 parts, benzoin dimethyl ether (651) 1 part, organic bentonite 6 parts, defoamer (Germany BYK chemical BYK-1790) 0.5 parts, polymerization inhibitor (p-hydroxyanisole) 0.5 parts, adhesion promoter (acid-modified Gram chemical BYK-354) 1 part, the above-mentioned components can be mixed to obtain endogenous frosting effect ink.

[0064] Curing conditions: the first strength is 80mw / cm 2 irradiate the coating with UV light for 40 seconds, and then use 250mw / cm 2 High-energy UV light exposure for 4 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com