Brightly colorful contact lens and preparation method thereof

A contact lens, color technology, applied in glasses/goggles, other home appliances, optics, etc., can solve the problems of low biocompatibility of contact lenses, foreign body sensation in patients wearing, poor comfort, etc., and achieve biocompatibility Excellent performance, mature program, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

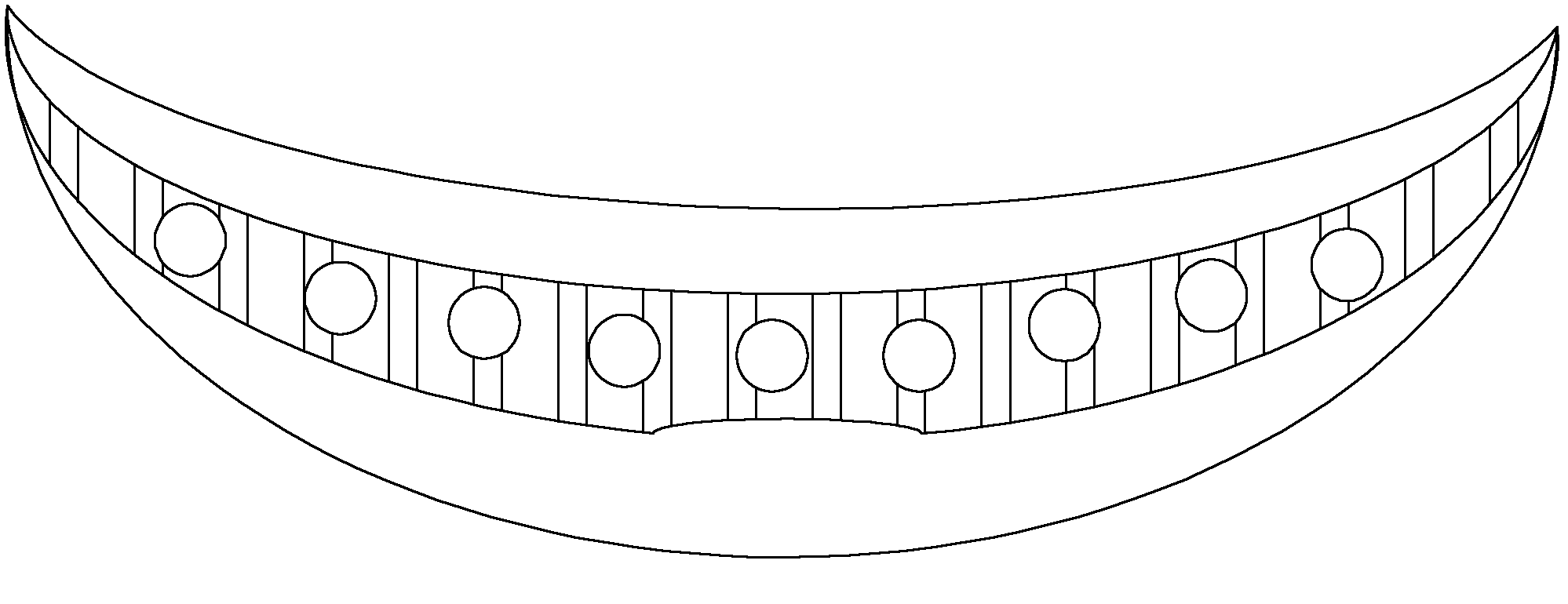

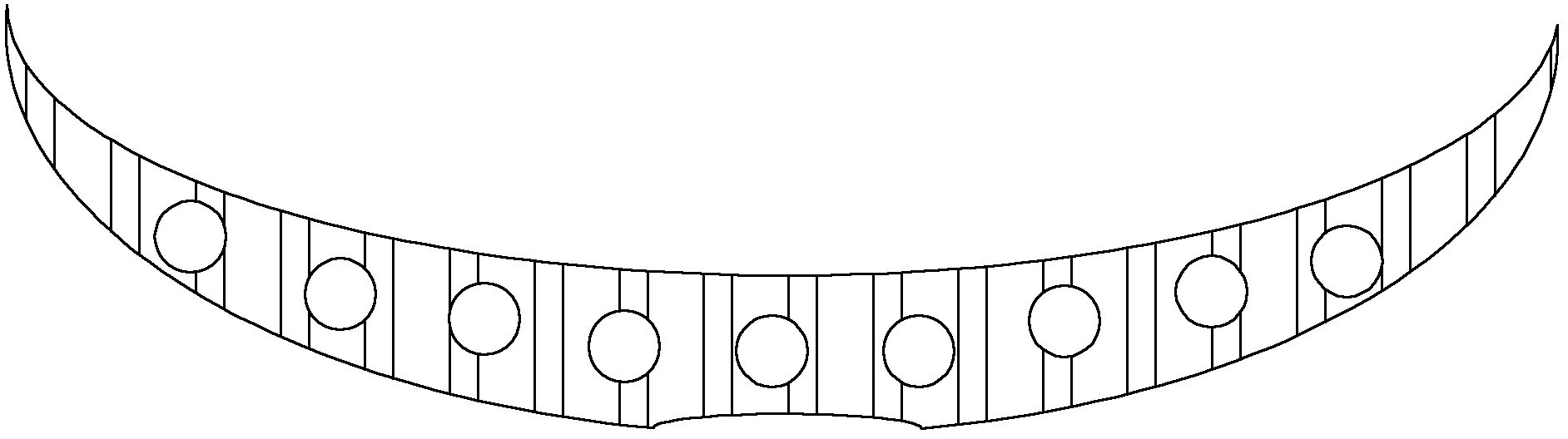

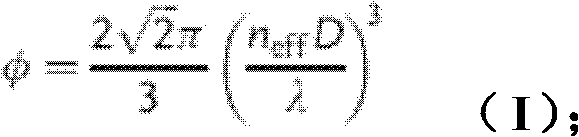

[0045] The preparation of embodiment 1 sandwich structure purple contact lens (SiO 2 template)

[0046] 1. Preparation of monodisperse silica colloidal particles

[0047] with intermittent feeding Method, add 88ml of absolute ethanol and 3.2ml of tetraethyl orthosilicate mixture and 20mL of ammonia water and 88ml of absolute ethanol mixture into the flask, stir at a speed of 350r / min; add 16ml of ammonia water; after 5-10 minutes Add 176ml of absolute ethanol and 4ml of ethyl orthosilicate mixture. After 2 hours, monodisperse silica particles were formed, and the particle size could be effectively controlled by changing the proportion of tetraethyl orthosilicate in the reaction system. After repeated ultrasonication and centrifugal washing to take out the reaction residual liquid, it was dispersed in deionized water, concentrated, and set aside.

[0048] The reaction temperature is controlled at 25 degrees, and the particle size can be controlled by changing the proportio...

Embodiment 2

[0058] The preparation of embodiment 2 sandwich structure red contact lenses (SiO 2 template)

[0059] The steps are as shown in Example 1, except that in step 2, 12 μl of AAm and Bis (29:1 in molar ratio) with a mass fraction of 60%, and 81 μl of silicon dioxide (180 nm in particle size) aqueous solution, 7 μl of PEGDA, 1 μl photoinitiator AIBN. Other treatment methods and conditions are similar to those in Example 1, and a red hydrogel film can be prepared, with a reflection peak of 650-700nm.

Embodiment 3

[0060] The preparation of embodiment 3 sandwich structure green contact lenses (SiO 2 template)

[0061] The steps are as shown in Example 1, except that the difference is that 18 μl of AAm and Bis (29:1 molar ratio) with a mass fraction of 60% is used, and 70 μl of silicon dioxide (particle diameter is 180 nm) aqueous solution, 11 μl of PEGDA, and 1 μl of photoinitiator AIBN. Other treatment methods and conditions are similar to those in Example 1, and a green hydrogel film can be prepared with a reflection peak of 580-620nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com