Ultraviolet (UV) glass protective printing ink

A technology for protecting ink and glass, applied in ink, household appliances, applications, etc., can solve the problem of glass being easily scratched, and achieve the effect of basically no shedding, improved yield, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

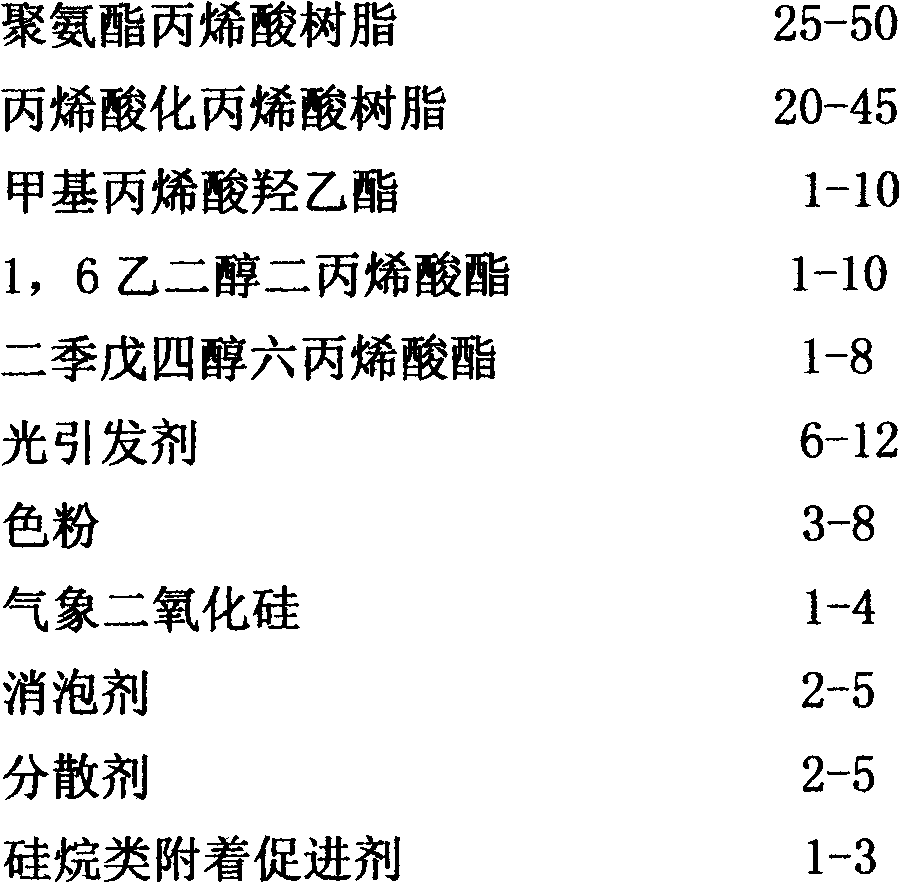

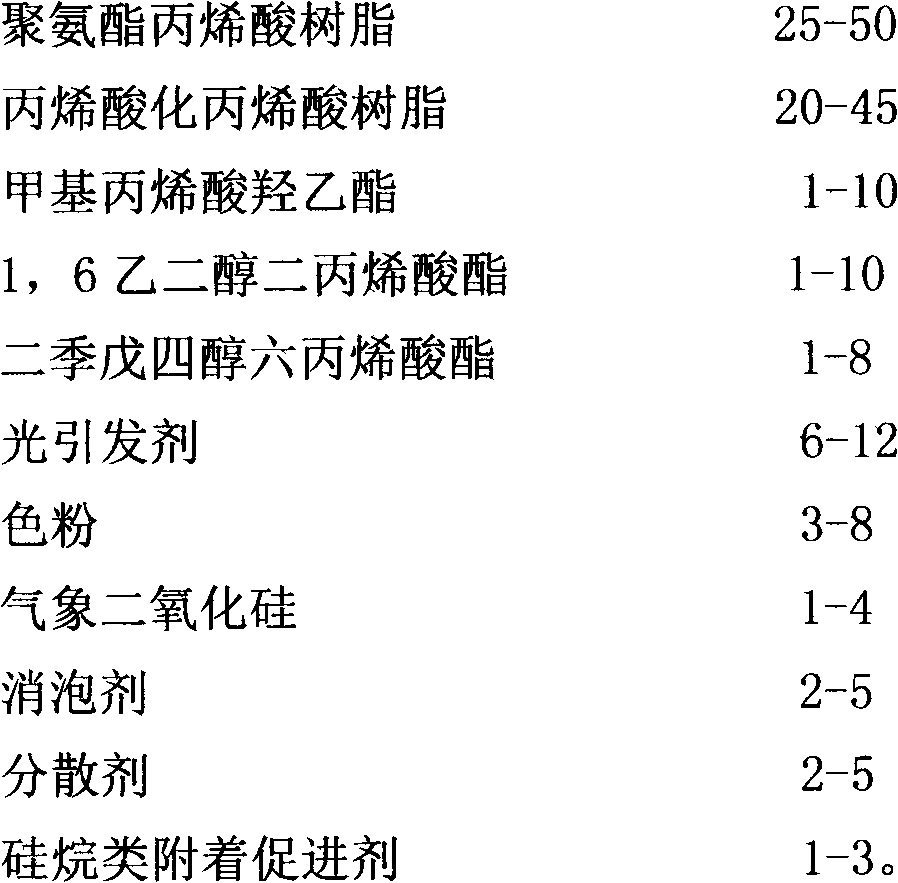

[0013] 1. Prepare the required raw materials according to the following parts by weight:

[0014] Polyurethane Acrylic Resin 25, Acrylated Acrylic Resin 35, Hydroxyethyl Methacrylate 5, 1,6 Ethylene Glycol Diacrylate 6, Dipentaerythritol Hexaacrylate 3, Photoinitiator 10, Toner 6, Meteorological Silica 3. Defoamer 2, dispersant 2, silane adhesion promoter 3.

[0015] 2. The specific configuration steps are as follows:

[0016] 1) Feed polyurethane acrylic resin, acrylated acrylic resin, hydroxyethyl methacrylate, 1,6 ethylene glycol diacrylate, and dipentaerythritol hexaacrylate according to the number of parts, stir for 5 minutes until uniform, and the stirring speed is 800-1000 rpm;

[0017] 2) Slowly add photoinitiator, defoamer, and dispersant according to the number of parts, and stir for 10-15 minutes at a stirring speed of 800-1000 rpm;

[0018] 3) Add the toner according to the number of parts, stir for 10-15 minutes, and the stirring speed is 1000-1500 rpm.

[001...

Embodiment 2

[0032] Polyurethane acrylic resin 25, acrylated acrylic resin 35, hydroxyethyl methacrylate 5, 1, 6 ethylene glycol diacrylate 6, dipentaerythritol hexaacrylate 5, photoinitiator 13, toner 2, meteorological silica 3, defoamer 2, dispersant 2, silane adhesion promoter 2

[0033] The specific configuration steps are the same as in Embodiment 1;

[0034] Printing and drying conditions are identical with embodiment 1;

[0035] The deinking method is the same as in Example 1.

[0036] The UV glass protection ink prepared in this embodiment is used to protect the touch screen glass in the process. In the deinking stage, the ink is not completely removed within 3-5 minutes, and the glass still remains. The test result shows that the glass is scratched at 1%. Contamination of 6%, compared with the traditional process, the rate of good products increased by 35%.

Embodiment 3

[0037] Example three polyurethane acrylic resin 25, acrylated acrylic resin 30, hydroxyethyl methacrylate 4, 1,6 ethylene glycol diacrylate 9, dipentaerythritol hexaacrylate 12, photoinitiator 8, toner 3, weather Silica 2, defoamer 3, dispersant 2, silane adhesion promoter 1

[0038] The specific configuration steps are the same as in Embodiment 1;

[0039] Printing and drying conditions are identical with embodiment 1;

[0040] The deinking method is the same as in Example 1.

[0041] The UV glass protection ink prepared in this example is used to protect the touch screen glass during processing. In the CNC stage, the edge of the ink is slightly off, and the inspection result is 13% scratched, which is 27% higher than the traditional process. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com