A method for analyzing free carbon

An analytical method and technology for free carbon, applied in the field of analytical chemistry, can solve the problem that free carbon cannot be directly measured, and achieve the effects of being easy to master, expanding the scope of application, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

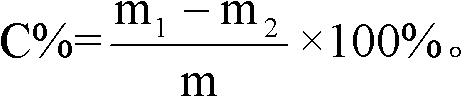

[0055] Get three vanadium carbide sample quality and be m=0.2000 gram, carry out three parallel tests according to the method of the present invention: first add the water wetting of about 10mL, add the sulfuric acid solution of 10mL (the volume ratio of sulfuric acid and water is about 1: 1 ), and then add 50g / L potassium permanganate solution, resulting in 2 drops of excess red in the solution, which does not fade after standing for 3 minutes, and oxidizes low-valent oxygen-containing vanadium to vanadium pentoxide.

[0056] Add about 0.5g of urea, adjust sodium nitrite with 1% solution until the solution is red, remove 2 drops of excess, and reduce the manganese dioxide and excess potassium permanganate produced by the reaction to Mn 2+ , the excess sodium nitrite is removed with urea, and the vanadium carbide and vanadium pentoxide are not reduced; filter, transfer the filter paper and the residue into a porcelain crucible, put it in a muffle furnace, and burn it to constan...

Embodiment 2

[0062] Since there is no vanadium carbide standard sample and high-purity vanadium carbide substance, the free carbon in the simulated vanadium carbon standard sample is measured to verify the accuracy of the determination of the present invention.

[0063] Simulated vanadium-carbon standard sample method: use vanadium-iron standard sample (V%=54.20%), and high-purity carbon powder (C%=99.85%) to synthesize vanadium-carbon in vanadium carbide, according to the composition of vanadium carbide: carbon: vanadium The mass ratio is about 4: 1 simulation, accurately weigh 175.00g ferrovanadium standard sample and 25.00g high-purity carbon powder, fully mix, the prepared standard sample, in this standard sample: V%=47.42%, C%= 12.48%.

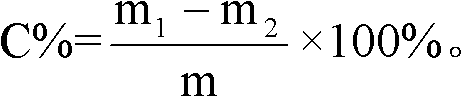

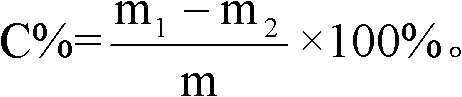

[0064] Weigh three copies of the above-mentioned vanadium-carbon standard samples with masses of 0.1000g, 0.1500g, and 0.2000g respectively, and carry out parallel determination of free carbon content according to the method of Example 1 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com