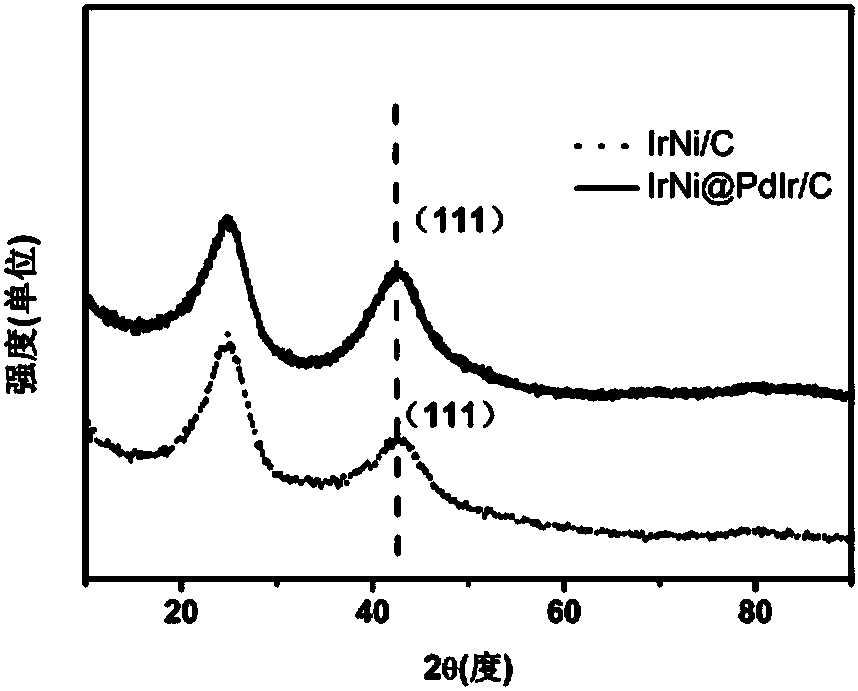

Hydroxide IrNi@PdIr/C core-shell catalyst for alkaline anion exchange film fuse cell and application thereof

A technology of alkaline anion and core-shell catalysts, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of slow exchange current density and achieve good stability, good hydrogen oxidation catalytic activity and stability, high hydrogen oxidation The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] preparation:

[0038] (1) Preparation of IrNi / C nanoparticles: take 0.1mM H 2 IrCl 6 , 0.3mM NiCl 2 , 102.4mg of XC-72 treated with 5M nitric acid reflux, 1mM trisodium citrate and 30ml ethylene glycol in a 100mL three-necked flask; stir ultrasonically for 30min; then add 2M NaOH aqueous solution drop by drop, adjust the pH to 9-12, and continue ultrasonic stirring And blow nitrogen for 15 minutes, then add excess 10% NaBH 4 Solution, reacted at 30°C for 3 hours, centrifuged, washed, and vacuum dried to prepare IrNi / C with a metal mass fraction of 15%, and the atomic ratio Ir:Ni=59:41;

[0039] (2) Preparation of IrNi@PdIr / C catalyst: Take 50 mg of IrNi / C prepared in (1) in a single-necked flask, then add 20 ml of a mixture of deionized water and isopropanol (volume ratio 1:1), and ultrasonically stir Each 30min, add excess 1mM / LPdCl 2 (HCl) aqueous solution was stirred and reacted for 1 h, placed in an oil bath at 40°C for 30 minutes, and subjected to centrifugal ...

Embodiment 2

[0041] preparation:

[0042] (1) Preparation of IrNi / C nanoparticles: take 0.1mM H 2 IrCl 6 , 0.2mM NiCl 2 , 102.4mg acid-treated XC-72, 1mM trisodium citrate, 30ml ethylene glycol in a 100mL three-neck flask; stir ultrasonically for 30min; then add 2M NaOH aqueous solution dropwise to adjust the pH to 9-12, continue ultrasonic stirring and pass Infuse nitrogen for 15 minutes, then add excess 10% NaBH 4 Solution, reacted at 30°C for 3 hours, centrifuged, washed, and vacuum dried to prepare IrNi / C with a metal mass fraction of 14.5%, and the atomic ratio Ir:Ni=63:37;

[0043] (2) Preparation of IrNi@PdIr / C catalyst: Take 50 mg of IrNi / C prepared in (1) in a single-necked flask, then add 20 ml of a mixture of deionized water and isopropanol (volume ratio 1:1), and ultrasonically stir Each 30min, add excess 1mM / LPdCl 2 (HCl) aqueous solution, control the reaction time to react for 60 minutes respectively, place it in an oil bath at 40°C for 30 minutes, and prepare 13.7% IrNi...

Embodiment 3

[0045] preparation:

[0046] (1) Preparation of IrNi / C nanoparticles: take 0.1mM H 2 IrCl 6 , 0.1mM NiCl 2 , 102.4mg acid-treated XC-72, 1mM sodium citrate and 30ml ethylene glycol in a 100mL three-neck flask; stir and ultrasonically 30min; then add 2M NaOH aqueous solution drop by drop, adjust the pH to 9-12, continue ultrasonic stirring and pass into Nitrogen for 15 min, then add excess NaBH 4 Solution, reacted at 30°C for 3 hours, centrifuged, washed, and vacuum dried to prepare IrNi / C with a metal mass fraction of 12.8%, and the atomic ratio Ir:Ni=63:37;

[0047] (2) Preparation of IrNi@PdIr / C catalyst: Take 50 mg of IrNi / C prepared in (1) in a single-necked flask, then add 20 ml of a mixture of deionized water and isopropanol (volume ratio 1:1), and ultrasonically stir Each 30min, add excess 1mM / LPdCl 2 (HCl) aqueous solution, control the reaction time to react for 60 minutes, place in an oil bath at 40°C for 30 minutes, and prepare the IrNi@PdIr / C catalyst with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com