Nano silver-coated copper powder and preparation method and application thereof

A technology of nano-silver and copper-coated powder, applied in the field of nanomaterials, can solve the problems of few research reports on silver-coated copper nanoparticles, increased resistivity of conductive patterns, complicated preparation process, etc., and achieves good conductivity and controllable particle size. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

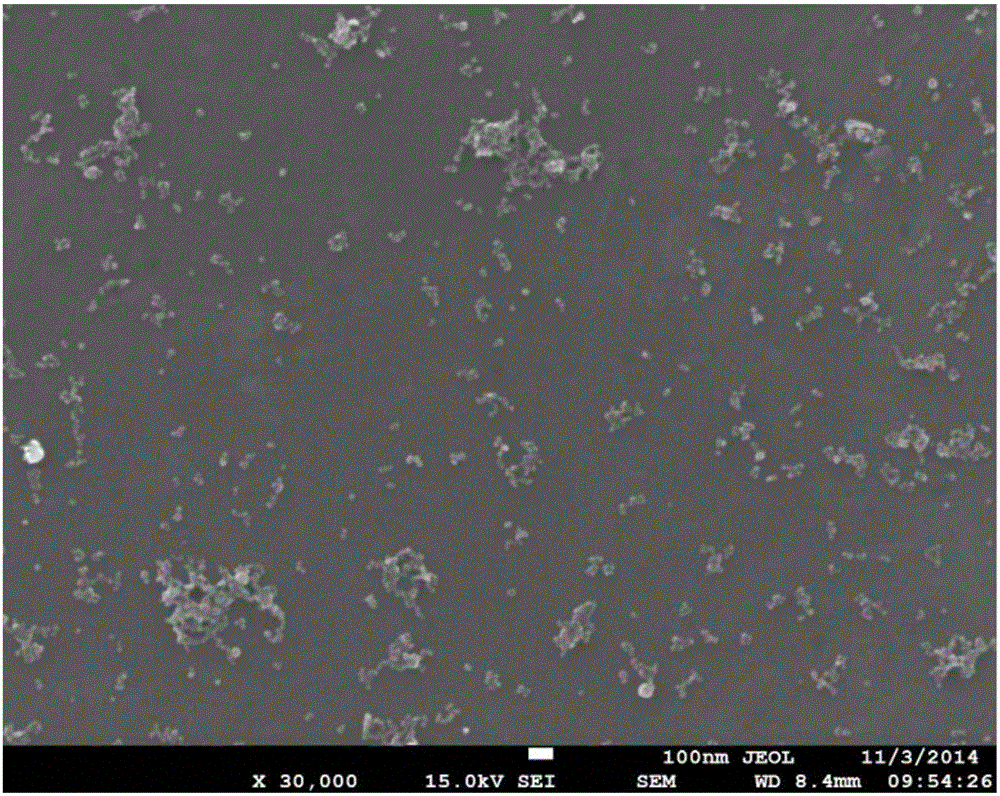

Image

Examples

Embodiment 1

[0031] The preparation method of nanometer silver-coated copper powder is:

[0032] Prepare 15 mL of copper sulfate solution with a concentration of 0.5 mol / L, add 0.0075 mol complexing agent sodium citrate, stir and dissolve to obtain a copper citrate solution, pour the copper citrate solution into a constant pressure dropping funnel for use; Add 0.015mol sodium borohydride, 0.0030mol cetyltrimethylammonium bromide and 0.0045mol polyvinylpyrrolidone to 100mL of 0.25mol / L sodium hydroxide solution, heat up to 50°C and stir to dissolve to obtain a reducing solution; Add the original solution into the reaction device, ventilate the air with nitrogen for 20 minutes, add the copper citrate solution dropwise, and stir and react at 50°C for 30 minutes under the condition of nitrogen to obtain nano-copper sol;

[0033] Add 20 mL of sulfuric acid solution with a concentration of 1.5 mol / L to the nano-copper sol, and after reacting for 5 minutes, adjust the pH to 6 with a sodium hydrox...

Embodiment 2

[0036] The preparation method of nanometer silver-coated copper powder is:

[0037] Prepare 20 mL of copper sulfate solution with a concentration of 0.5 mol / L, add 0.015 mol complexing agent sodium citrate, stir and dissolve to obtain a copper citrate solution, pour the copper citrate solution into a constant pressure dropping funnel for use; Add 0.03mol sodium borohydride, 0.01mol cetyltrimethylammonium bromide and 0.015mol polyvinylpyrrolidone to 150mL of 0.25mol / L sodium hydroxide solution, heat up to 30°C and stir to dissolve to obtain a reducing solution; Add the original solution into the reaction device, ventilate the air with nitrogen for 40 minutes, add copper citrate solution dropwise, and stir and react at 30°C for 60 minutes under the condition of nitrogen, to obtain nano-copper sol;

[0038] Add 20 mL of sulfuric acid solution with a concentration of 1.5 mol / L to the nano-copper sol, and after reacting for 8 minutes, adjust the pH to 6.5 with a sodium hydroxide so...

Embodiment 3

[0041] The preparation method of nanometer silver-coated copper powder is:

[0042]Prepare 30 mL of copper sulfate solution with a concentration of 0.8 mol / L, add 0.048 mol complexing agent sodium citrate, stir and dissolve to obtain a copper citrate solution, pour the copper citrate solution into a constant pressure dropping funnel for use; Add 0.096mol sodium borohydride and 0.036mol polyvinylpyrrolidone to 120mL of 0.5mol / L sodium hydroxide solution, heat up to 40°C and stir to dissolve to obtain a reducing solution; add the reducing solution to the reaction device, blow nitrogen for 30min to discharge the air, drop Add copper citrate solution, stir and react for 50 minutes at 40°C under nitrogen atmosphere, to obtain nano-copper sol;

[0043] Add 15 mL of sulfuric acid solution with a concentration of 2 mol / L to the nano copper sol, and after reacting for 8 minutes, adjust the pH to 6 with a sodium hydroxide solution with a concentration of 1.8 mol / L to obtain a nano coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com