Double-tank method for production of sodium fluorosilicate

A technology of sodium fluorosilicate and fluorosilicic acid, which is applied in the direction of fluorosilicic acid and silicon halide compounds, can solve the problems of reduced raw material consumption, high raw material consumption, and fouling of the production system, and achieves improved utilization, high purity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

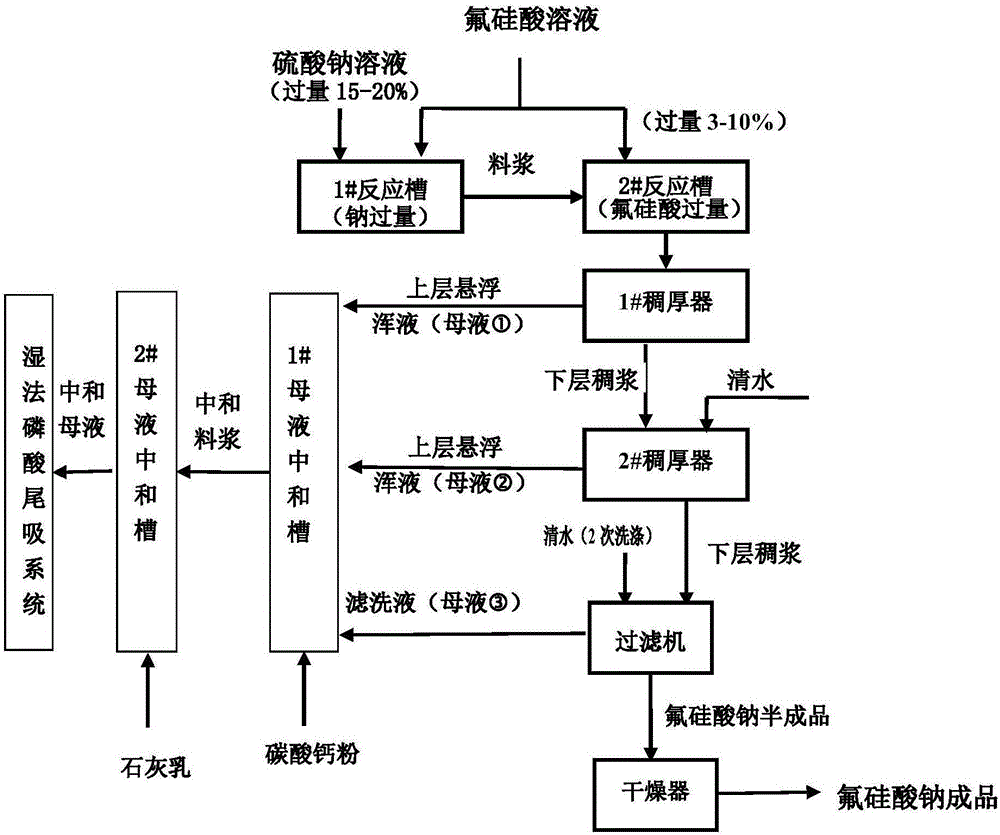

Method used

Image

Examples

Embodiment 1

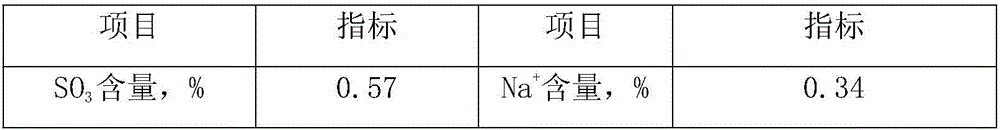

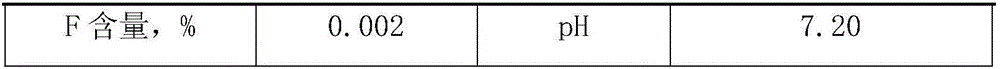

[0029] Will contain H 2 SiF 6 %-8.37 of the fluorosilicic acid slurry from the concentrated acid workshop. The filtrate after filtration and the sodium sulfate solution with a concentration of 30% are added to the 1# reaction tank to make the sodium sulfate solution in the reaction tank over 18%, and stir at 43℃ After reacting for 40 minutes, send the reaction slurry to 2# reaction tank, and add H-containing to 2# reaction tank 2 SiF 6 %-8.37 of fluorosilicic acid solution, make the 2# reaction tank excessive 5% of fluorosilicic acid. After stirring and reacting at 43°C for 40min, the reaction slurry is sent to 1# thickener for sedimentation and thickening for 3min, and the upper layer is separated Suspended muddy liquid is the mother liquor of sodium fluorosilicate containing part of silica gel ① Enter the mother liquor neutralization tank, the lower thick slurry in the tank is sent to the 2# thickener, add clean water and stir evenly, then carry out the second sedimentation and...

Embodiment 2

[0039] Will contain H 2 SiF 6 %-9.64 fluorosilicic acid slurry from the concentrated acid workshop. The filtrate after filtration and the sodium sulfate solution with a concentration of 30% are added to the 1# reaction tank so that the sodium sulfate solution in the reaction tank is excessively 20% and stirred at 44℃ After reacting for 40 minutes, send the reaction slurry to 2# reaction tank, and add H-containing to 2# reaction tank 2 SiF 6 %-9.64 of fluorosilicic acid solution, make the 2# reaction tank 7% of fluorosilicic acid, stir and react at 44℃ for 40min, then send the reaction slurry to 1# thickener for sedimentation and thickening for 3.5min, then separate The upper suspension muddy liquid is the mother liquor of sodium fluorosilicate containing part of silica gel ① enters the 1# mother liquor neutralization tank, the lower thick slurry in the tank is sent to the 2# thickener, and the clear water is added and stirred evenly, and then the second sedimentation thickness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com