Composite flocculant preparation and heavy metal organic matter-containing tailings wastewater treatment method

A composite flocculant and treatment method technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of ineffective treatment of composite wastewater in mining areas and heavy metal ion chelation ability Low, persistent hazards to the ecological environment and other issues, to achieve the effect of improving comprehensive treatment performance, small secondary pollution, and short flocculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of composite flocculant, and this method comprises the following steps:

[0044] Step 1, add the nitrate solution solution of mixed metal ions with a total concentration of 0.5mol / L into 2mol / L preheated sodium hydroxide solution to make a precipitant, slowly add the mixed metal ion solution under stirring, and use the mass concentration Adjust the pH value to 10.5 for 10% ammonia water, let stand, wash repeatedly with distilled water, filter with suction, and dry to constant weight in a vacuum oven at 90-110°C to obtain magnesium copper zinc ferrite (Mg 0.25 Cu 0.25 Zn 0.5 Fe 2 o 4 , referred to as Ferrite).

[0045] The nitrate solution of the mixed metal ions is a mixed nitrate solution of magnesium ions, copper ions, zinc ions and iron ions; the magnesium ions, copper ions, zinc ions and iron ions in the nitrate solution of the mixed metal ions The molar ratio between them is 1:1:1:1;

[0046] The to...

Embodiment 2

[0064] The present embodiment provides a kind of preparation method of composite flocculant, and this method comprises the following steps:

[0065] Step 1 is the same as Step 1 of Embodiment 1.

[0066] Step 2 is the same as Step 2 of Embodiment 1.

[0067] Step 3, step 3, using polyethyleneimine (PEI) as the matrix, under the condition of the polypeptide reagent (EDC·HCL) as the initiator, adding excess thioglycolic acid, carrying out amidation reaction, adjusting pH=2.0 with hydrochloric acid, Stir the reaction at 40°C for 12 hours to obtain mercaptoacetylethyleneimine.

[0068] The polypeptide reagent is 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl).

[0069] The molar ratio between polyethyleneimine, thioglycolic acid and peptide reagent is 1:2:0.2.

[0070] Step 4 is basically the same as Step 4 in Embodiment 1.

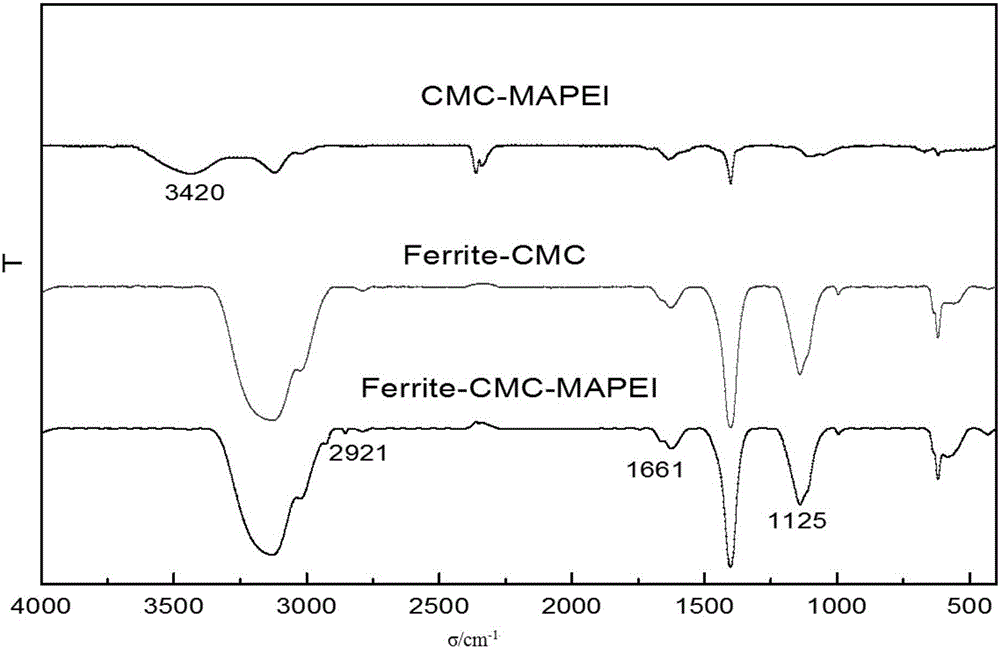

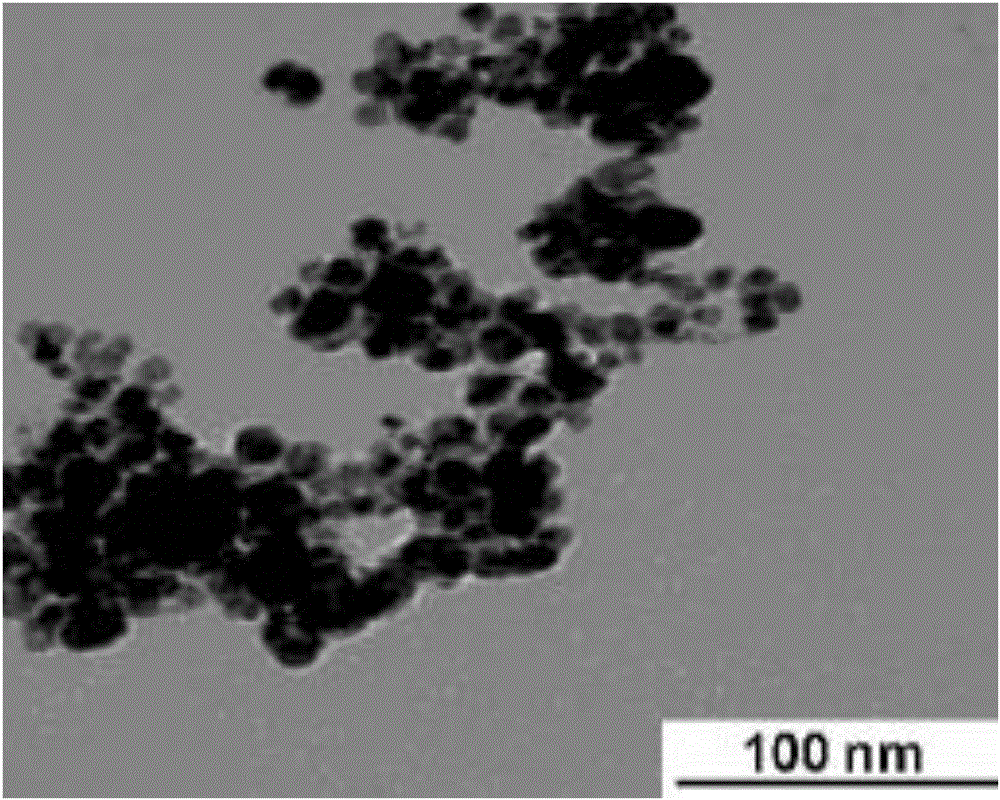

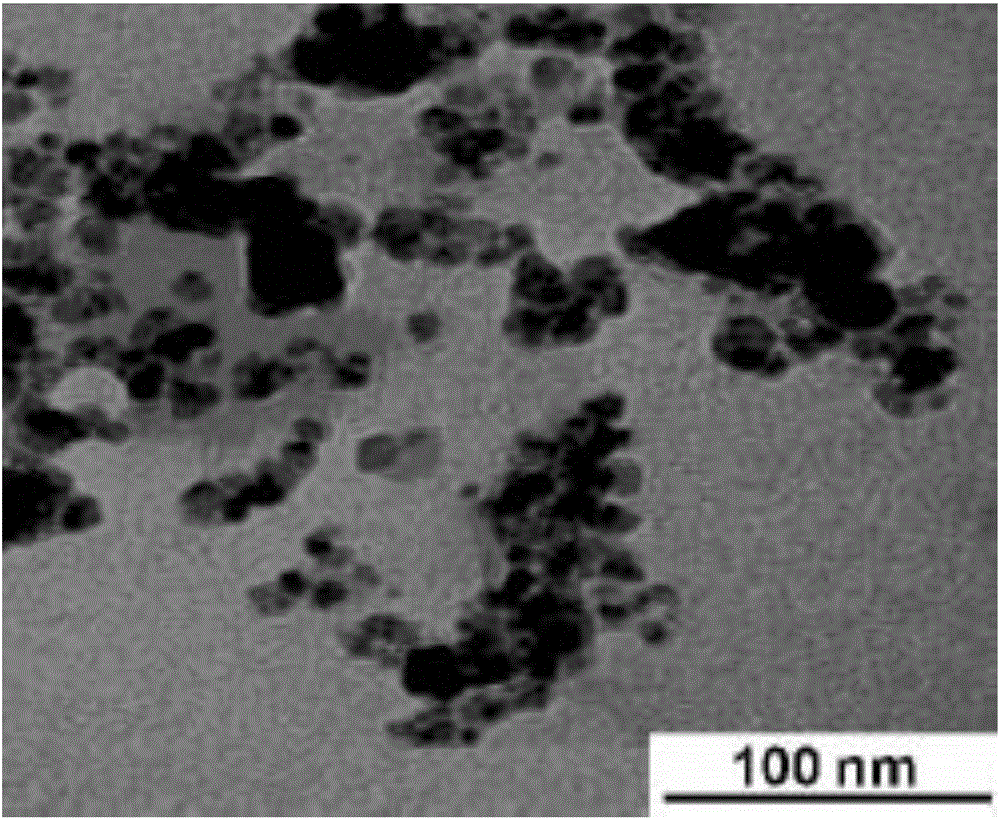

[0071] The characterization results of the composite flocculant Ferrite-CMC-MAPEI prepared in this example are the same as those in ...

Embodiment 3

[0073] The present embodiment provides a kind of preparation method of composite flocculant, and this method comprises the following steps:

[0074] Step 1 is the same as Step 1 of Embodiment 1.

[0075] Step 2 is the same as Step 2 of Embodiment 1.

[0076] Step 3, step 3, using polyethyleneimine (PEI) as the matrix, under the condition of the polypeptide reagent (EDC·HCL) as the initiator, adding excess thioglycolic acid, carrying out amidation reaction, adjusting pH=1.0 with hydrochloric acid, Stir the reaction at 30°C for 12 hours to obtain mercaptoacetylethyleneimine.

[0077] The polypeptide reagent is 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl).

[0078] The molar ratio between polyethyleneimine, thioglycolic acid and peptide reagent is 1:1:0.1.

[0079] Step 4 is basically the same as Step 4 in Embodiment 1.

[0080] The characterization results of the composite flocculant Ferrite-CMC-MAPEI prepared in this example are the same as those in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com