Method of producing powdered soap by using vegetable oil alkali refining nigre containing phospholipid

A vegetable oil and alkali refining technology, applied in the direction of alkali soap/ammonium soap composition, etc., can solve the problems of wasting raw materials, polluting the environment, insufficient utilization of vegetable oil alkali refining soap stock, etc., to avoid waste of raw materials and easy to degrade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

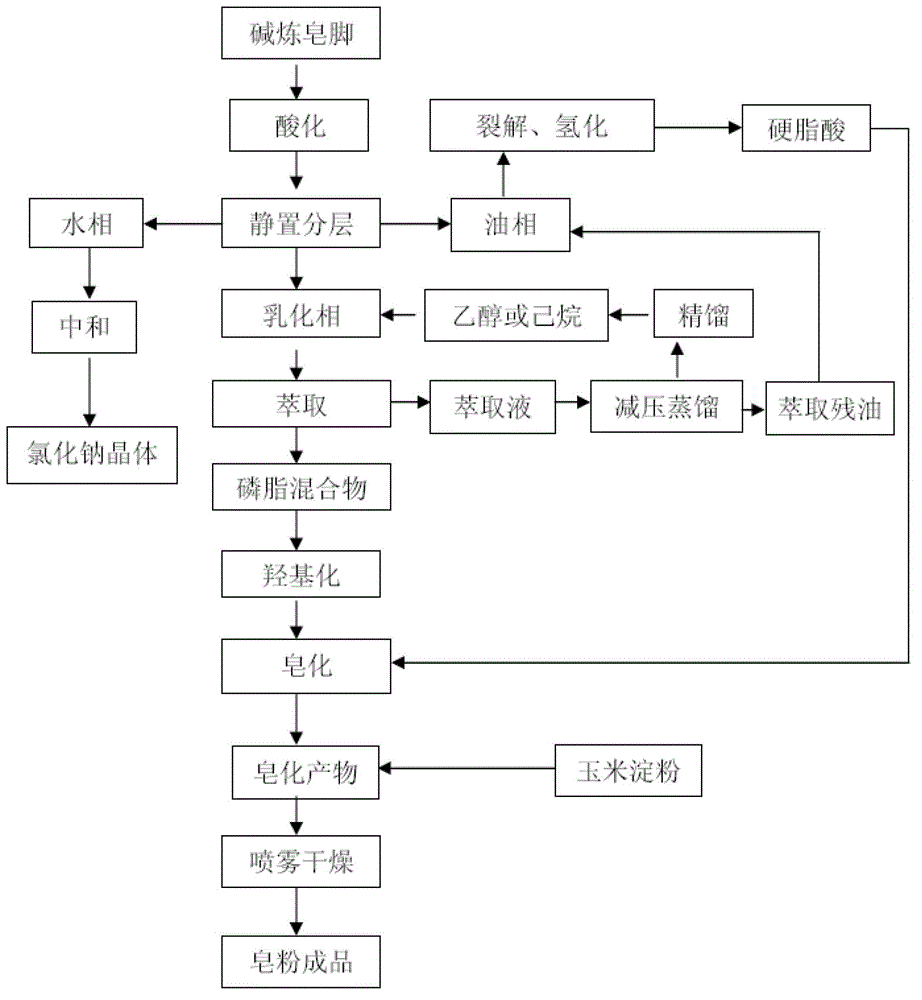

[0029] The present embodiment provides a kind of method that utilizes phospholipid-containing vegetable oil alkali to refine soapstock to produce soap powder, and its concrete process is as follows figure 1 shown. The method includes the following steps:

[0030] Add the vegetable oil alkali refining soapstock into the stirring reaction tank, add concentrated hydrochloric acid with a concentration of 36%, adjust the pH of the soapstock to 1, stir and acidify the soapstock at 50°C and normal pressure for 30 minutes; then let it stand for 4 hours and separate the layers , to separate the water phase, emulsified phase and oil phase respectively;

[0031] Put the oil phase into the reaction kettle, then add water accounting for 10% of the weight of the oil phase, react at 5MPa and 263°C for 10 minutes, crack the triglycerides in the oil phase to generate fatty acids, separate the fatty acids, and then heat them at 200°C , 2MPa, 0.1% nickel catalyst conditions, feed hydrogen to r...

Embodiment 2

[0039] The present embodiment provides a kind of method that utilizes phospholipid-containing vegetable oil alkali to refine soapstock to produce soap powder, and its concrete process is as follows figure 1 shown. The method includes the following steps:

[0040] Add the vegetable oil alkali refining soapstock into the stirring reaction tank, add concentrated hydrochloric acid with a concentration of 15wt%, adjust the pH of the soapstock to 3, stir and acidify at 70°C and normal pressure for 60 minutes, and then let it stand for 8 hours after stratification , to separate the water phase, emulsified phase and oil phase respectively;

[0041] Put the oil phase into the reaction kettle, then add water accounting for 10% of the mass of the oil phase, react at 1MPa and 180°C for 60 minutes, crack the triglycerides in the oil phase to generate fatty acids, separate the fatty acids, and then .

[0042] The separated aqueous phase can be prepared to obtain sodium chloride after neu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com