Method of lowering content of calcium in recovered cryolite

A cryolite and calcium content technology, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems that the calcium content cannot meet the index requirements, the quality of recovered cryolite is not high, and the recycling of cryolite is affected, and the method is simple and economical. Raw materials, strong operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

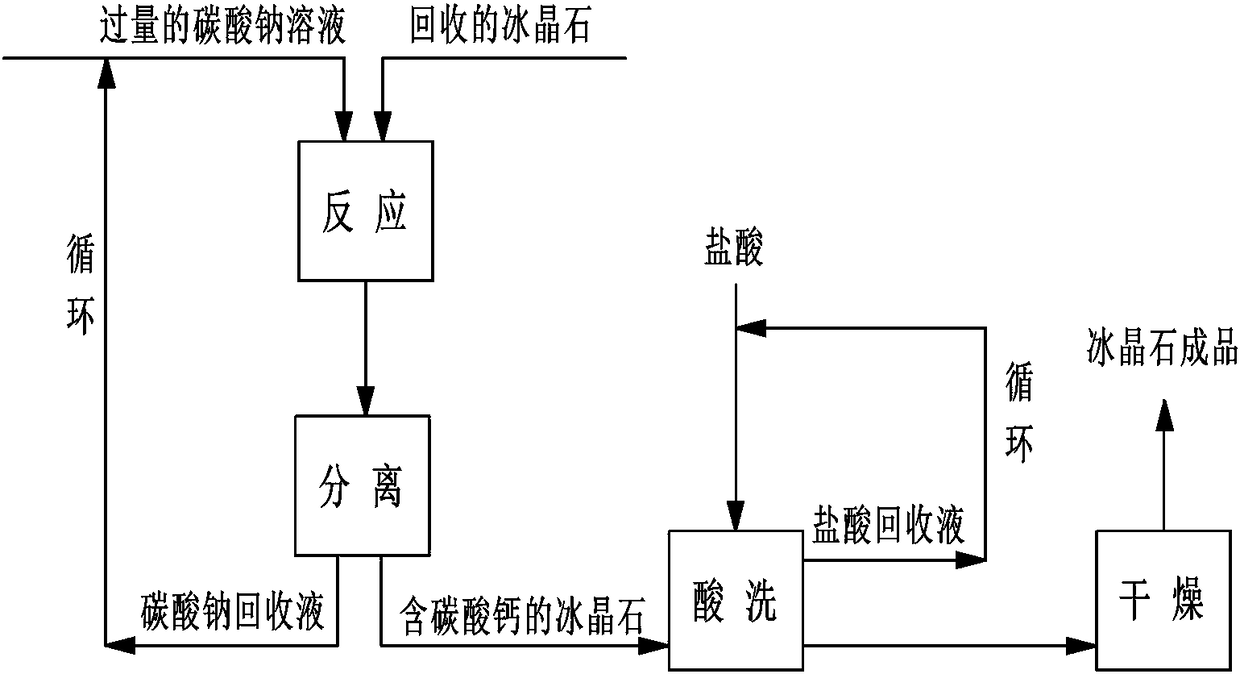

[0025] See figure 1 , the embodiment of the present invention provides a kind of method that reduces the calcium content in reclaiming cryolite, it comprises the following steps:

[0026] Step 1, providing a cryolite recovered from electrolytic aluminum waste slag by flotation, calcium fluoride in the recovered cryolite;

[0027] Step 2, detecting that the content of calcium fluoride in the recovered cryolite is 3.5 wt.%, adding the sodium carbonate solution with a concentration of 1 mol / L to the recovered cryolite, and the recovered The solid-to-liquid ratio of the cryolite to the added sodium carbonate solution is 1:1, stirring continuously for 3 h, so that the calcium fluoride in the recovered cryolite reacts with sodium carbonate to generate calcium carbonate, and a solid-liquid mixture containing calcium carbonate is obtained The solid-liquid mixture containing calcium carbonate is separated and processed to obtain calcium carbonate-containing cryolite and sodium carbona...

Embodiment 2

[0033] The present embodiment provides a kind of method that reduces calcium content in reclaiming cryolite, and the method that this method provides with embodiment 1 is substantially the same, and difference is:

[0034] In described step 2, the content of the calcium fluoride in the cryolite of described recovery is 2.7 wt.%, the concentration of described sodium carbonate solution is 0.5 mol / L, the cryolite of described recovery and the sodium carbonate that adds The solid-liquid ratio of the solution is 1:2, stirring for 2 h; the step of obtaining the sodium carbonate recovery solution comprises: filtering the solid-liquid mixture containing calcium carbonate to obtain the sodium carbonate filtrate and the cryolite precursor containing calcium carbonate; The cryolite precursor containing calcium carbonate is washed with water to obtain the cryolite containing calcium carbonate and the washing liquid containing sodium carbonate; the sodium carbonate filtrate and the washing...

Embodiment 3

[0037] This embodiment provides a method for reducing the calcium content in the recovered cryolite, which is basically the same as the method provided in Example 1, except that in the step 2, the fluorination in the recovered cryolite The content of calcium is 4.4 wt.%, the concentration of described sodium carbonate solution is 3 mol / L, and the solid-liquid ratio of described cryolite and the sodium carbonate solution that adds is 1: 1.5; In described step 3, The calcium content in the final cryolite product is 0.5 wt %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com