High-r-aminobutyric-acid-content highland-barley red yeast and preparation method thereof

A technology of aminobutyric acid and highland barley red yeast rice, which is applied in the field of biotechnology food, can solve the problems of low content of r-aminobutyric acid and the like, and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

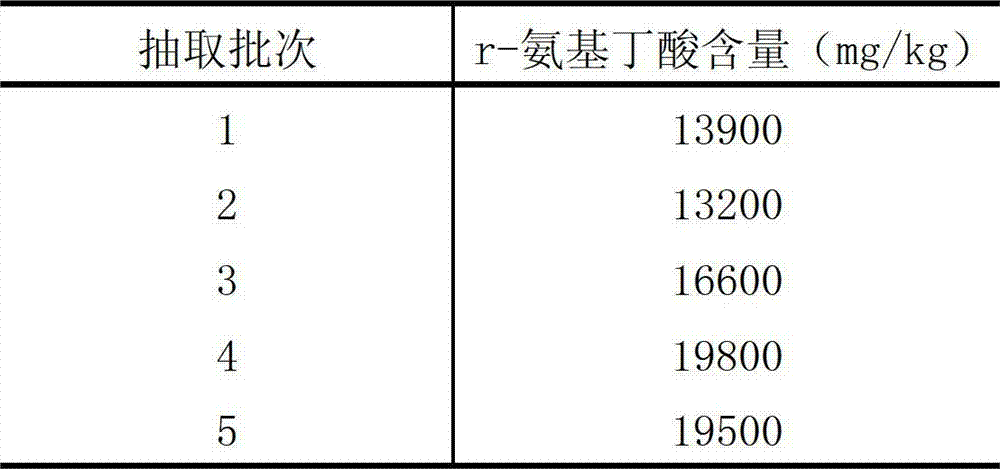

Image

Examples

Embodiment 1

[0042] The high-content r-aminobutyric acid highland barley red yeast rice of the present embodiment is prepared according to the following steps:

[0043] 1) Prepare slant medium:

[0044] Take 20g of potato slices, 2g of glucose, 2g of sucrose, 0.5g of yeast extract, 1g of peptone, and 1g of agar powder, mix well, adjust the pH to 5.5, and sterilize at 121°C for 30 minutes after bottling;

[0045] 2) Prepare seed medium:

[0046] Take 7g of glucose, 0.2g of yeast extract, 0.6g of sodium glutamate, 0.1g of sodium nitrate, 0.05g of magnesium sulfate, 0.1g of potassium dihydrogen phosphate, and 0.001g of ferric sulfate, stir evenly, adjust the pH to 5.5, and pack in cans Sterilize at 121°C for 30 minutes

[0047] 3) Preparation of green barley buds:

[0048] Take full-bodied barley, wash it, soak it in water for 40 hours, drain it, and put it in an incubator at 25°C for 36 hours. During the activation period, take vitamin B with a concentration of 30ml / L. 6 Spray the surfac...

Embodiment 2

[0074] The high-content r-aminobutyric acid highland barley red yeast rice of the present embodiment is prepared according to the following steps:

[0075] 1) Prepare slant medium:

[0076] Take 18g of potato slices, 3g of glucose, 1g of sucrose, 1g of yeast extract, 0.5g of peptone, and 2g of agar powder, stir evenly, adjust the pH to 5.5, and sterilize at 121°C for 30 minutes after bottling;

[0077] 2) Prepare seed medium:

[0078] Take 5g of glucose, 0.3g of yeast extract, 0.4g of sodium glutamate, 0.2g of sodium nitrate, 0.05g of magnesium sulfate, 0.1g of potassium dihydrogen phosphate, and 0.001g of iron sulfate, stir evenly, adjust the pH to 5.5, and pack into tanks Sterilize at 121°C for 30 minutes

[0079] 3) Preparation of green barley buds:

[0080] Take full-bodied highland barley, wash it, soak it in water for 24 hours, drain it, and put it in an incubator at 25°C for 48 hours. During the activation period, take vitamin B with a concentration of 30ml / L. 6 Spr...

Embodiment 3

[0106] The high-content r-aminobutyric acid highland barley red yeast rice of this embodiment is prepared according to the following steps:

[0107] 1) Prepare slant medium:

[0108] Take 18-20g of potato slices, 2-3g of glucose, 1-2g of sucrose, 0.5-1g of yeast extract, 0.5-1g of peptone, 1-2g of agar powder and stir evenly, adjust the pH to 5.5, and sterilize at 121°C after bottling 30 minutes;

[0109] 2) Prepare seed medium:

[0110] Take 5-7g of glucose, 0.2-0.3g of yeast extract, 0.4-0.6g of sodium glutamate, 0.1-0.2g of sodium nitrate, 0.05g of magnesium sulfate, 0.1g of potassium dihydrogen phosphate, and 0.001g of iron sulfate and stir evenly. Adjust the pH to 5.5, and sterilize at 121°C for 30 minutes after dispensing

[0111] 3) Preparation of green barley buds:

[0112] Take full-bodied highland barley, wash it, soak it in water for 24-40 hours, drain it, and put it in an incubator at 25°C for 36-48 hours. During the activation period, take 30ml / L vitamin B6 aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com