Method for continuously synthesizing nickel carbonate

A synthesis method and technology of nickel carbonate, applied in directions such as nickel carbonate, can solve the problems of high impurity content of nickel carbonate, wide interval between colorimetric cards, and difficulty in removal, etc., and achieve the effect of improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

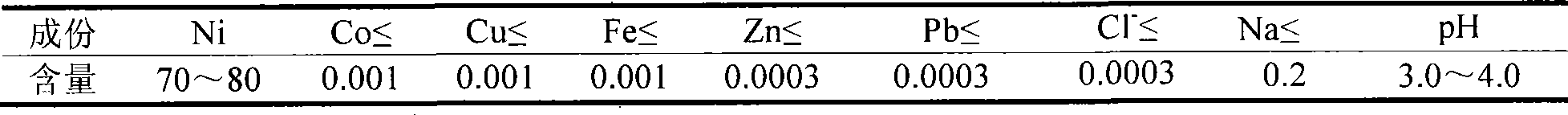

[0025] Preparation of nickel sulfate solution Ni 2+ : 50g / l, concentration of dissolved sodium carbonate solution: 125g / l, after heating the two solutions respectively, they are continuously co-currently and quantitatively added to the synthesis kettle through an automatic metering device, and the pH value of the synthesis process is controlled to be 8.3 to 8.6. After aging, The high-quality nickel carbonate products obtained after washing are shown in the table below.

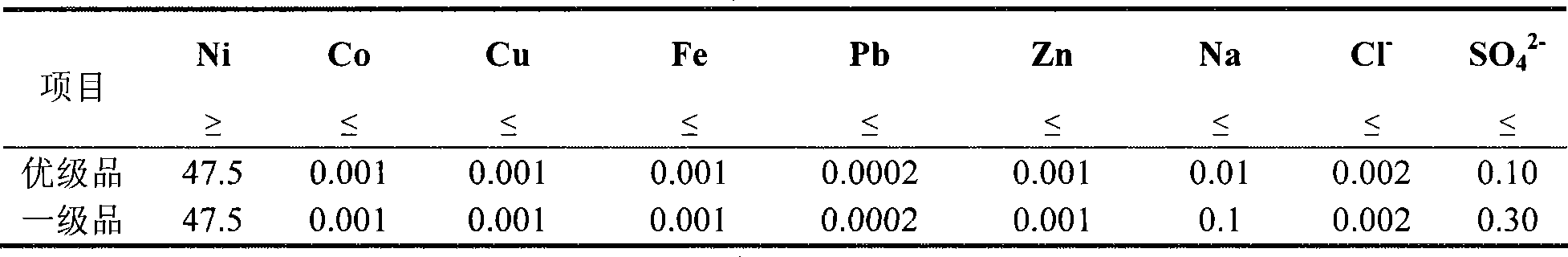

[0026] Composition of high-quality nickel carbonate products / %

[0027]

Embodiment 2

[0029] Preparation of nickel sulfate solution Ni 2+ : 50g / l, concentration of dissolved sodium carbonate solution: 120g / l, after heating the two solutions respectively, they are continuously co-currently and quantitatively added to the synthesis kettle through an automatic metering device, and the pH value of the synthesis process is controlled to be 8.3 to 8.6. After aging, The high-quality nickel carbonate products obtained after washing are shown in the table below.

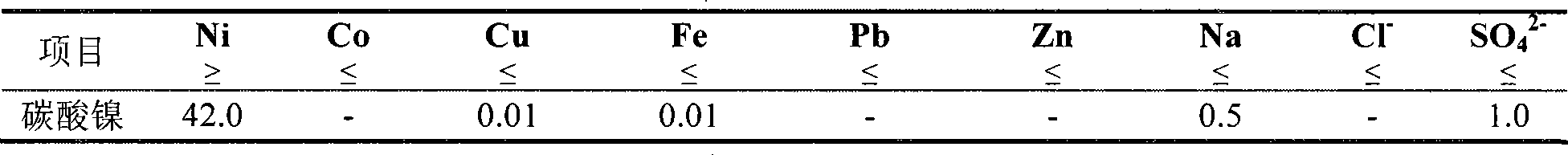

[0030] Composition of high-quality nickel carbonate products / %

[0031]

Embodiment 3

[0033] Preparation of nickel sulfate solution Ni 2+ : 55g / l, the concentration of dissolved sodium carbonate solution: 125g / l, after heating the two solutions respectively, they are continuously co-currently and quantitatively added to the synthesis kettle through an automatic metering device, and the pH value of the synthesis process is controlled to be 8.3 to 8.6. After aging, The high-quality nickel carbonate products obtained after washing are shown in the table below.

[0034] Composition of high-quality nickel carbonate products / %

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com