Fluorgypsum-based repair mortar

A technology for repairing mortar and fluorine gypsum, applied in the field of building materials, can solve the problems of poor weather resistance of organic caulks, large shrinkage of cement-based materials, low strength of semi-aqueous gypsum, etc., so as to improve water resistance and tensile bond strength. High, avoid anti-alkali and surface yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

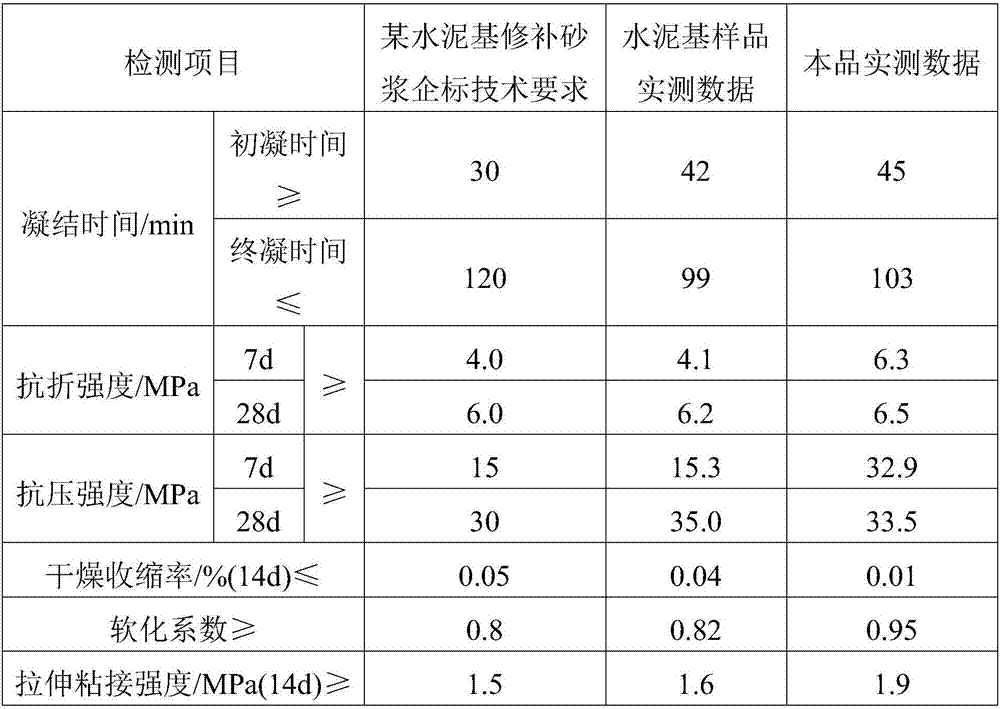

Embodiment 1

[0031] A kind of fluorine gypsum-based repairing mortar, including main ingredients and additives, in parts by mass, the main ingredients include the following components: 70 parts of fluorogypsum, 5 parts of Portland cement, 25 parts of aggregate; The agent includes the following components: 0.5 parts of sodium sulfate, 2 parts of alkaline earth metal oxides, 0.5 parts of polycarboxylic acid, 0.1 parts of polyvinyl alcohol, 0.5 parts of redispersible emulsion agent, and 0.4 parts of organic fluorine silicon protective agent.

[0032] Wherein, Portland cement is fly ash Portland cement, which is the active mineral admixture; the aggregate is 10 parts of 80-mesh quartz sand, 10 parts of 160-mesh quartz sand and 5 parts of 200-mesh quartz sand; Sodium sulfate is the activator; alkaline earth metal oxide is the coagulation regulator; polycarboxylic acid is the water reducer; polyvinyl alcohol is the water-retaining thickener; agent.

[0033] During preparation, add fluorinated g...

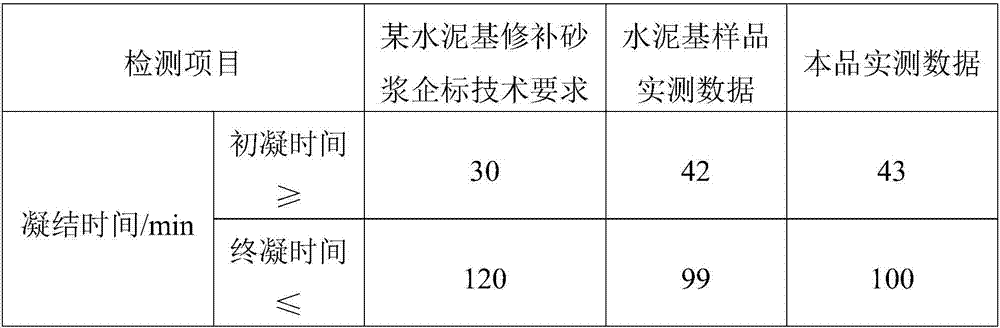

Embodiment 2

[0039] A kind of fluorine gypsum-based repair mortar, including main material and admixture, in parts by mass, the main material includes the following components: 50 parts of fluorine gypsum, 5 parts of Portland cement and 5 parts of blast furnace slag powder, aggregate 35 parts; the admixture includes the following components: 3 parts of potassium sulfate, 1 part of carbonate compound, 0.5 part of melamine, 0.5 part of polycarboxylic acid, 0.5 part of hydroxymethyl propyl cellulose, redispersible 1 part of latex agent, 0.2 part of silicate protective agent.

[0040] Wherein, the Portland cement is fly ash Portland cement, Portland cement and blast furnace slag powder are the active mineral admixture; the aggregate is 20 parts of 80 mesh quartz sand, 10 parts of 160 mesh quartz sand And 5 parts of 200 mesh quartz sand; Potassium sulfate is the activator; Carbonate compound is the coagulation regulator; Trimeric nitrile amine and polycarboxylic acid are the water reducing agen...

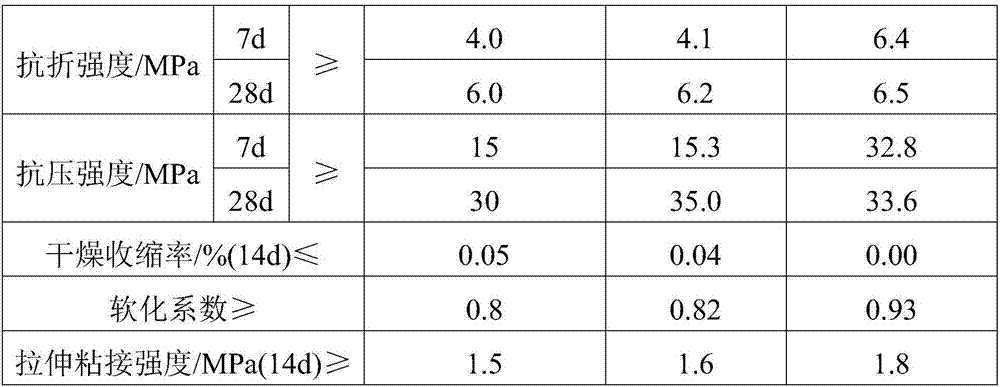

Embodiment 3

[0048] A fluorogypsum-based repair mortar, comprising main ingredients and admixtures, the main ingredients include the following components in parts by mass: 25 parts of fluorogypsum, 2 parts of Portland cement, 1 part of silica fume, blast furnace slag powder 7 parts, 65 parts of aggregate; the admixture includes the following components: 1 part of potassium aluminum sulfate, 2 parts of alkaline earth metal oxide, 1 part of carbonate compound, 0.5 part of benzene-based water reducer, 0.4 part of polyvinyl alcohol , 0.1 part of hydroxymethyl propyl cellulose, 1 part of redispersible emulsion agent, 0.3 part of organic fluorocarbon protective agent.

[0049] Wherein, the Portland cement is fly ash Portland cement, Portland cement, silica fume and blast furnace slag powder are the active mineral admixture; the aggregate is 20 parts of 80 mesh quartz sand, 20 parts of 160 mesh quartz sand and 15 parts of 200 mesh quartz sand; aluminum potassium sulfate is the activator; alkaline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com