Silicon tetrafluoride purifying method

A technology of silicon tetrafluoride and purification method, applied in halogenated silicon compounds, chemical instruments and methods, halogenated silanes, etc., can solve the problems of high requirements for production equipment, high production cost, low temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

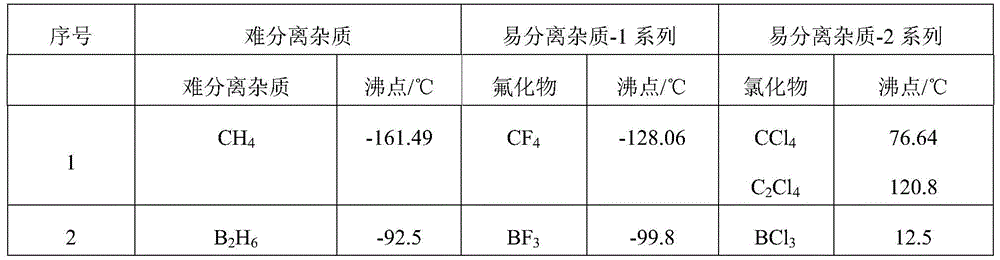

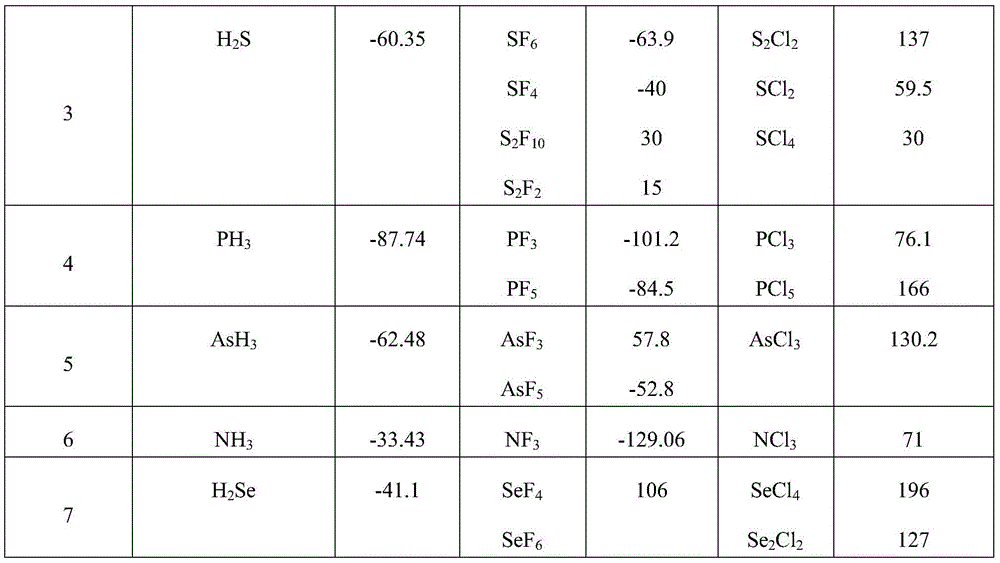

Image

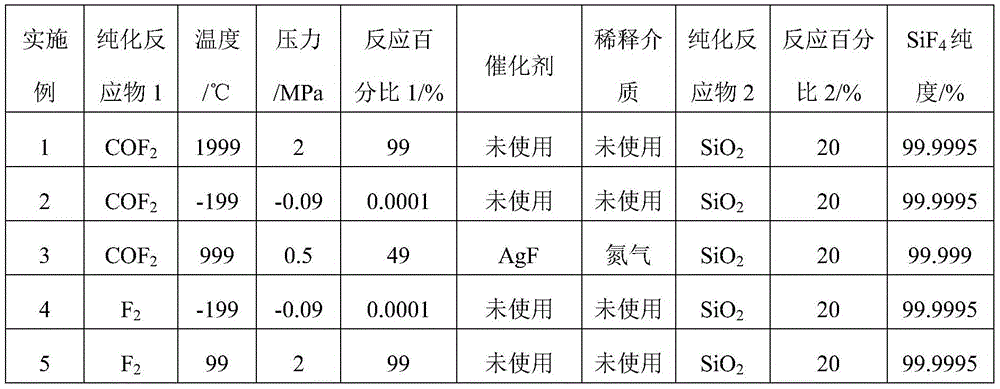

Examples

Embodiment 1~27

[0078] In the purification method of following embodiment 1~27 silicon tetrafluorides:

[0079] The purification apparatus used is as follows:

[0080]A purification device for silicon tetrafluoride, the purification device is made of Monel alloy, the reaction chamber has a volume of 5L, is equipped with a heating tile and a cooling jacket, the diameter of the reaction chamber is 100mm, and is connected with a dilution medium inlet pipe. If it is necessary to use a catalyst, the catalyst can be placed in the reaction chamber before the purification reaction, and if it is necessary to use a dilution medium, the dilution medium can be added through the dilution medium inlet pipe during the purification reaction. During the reaction, the reactor passes through a feed pipe, feeds the crude silicon tetrafluoride gas, and feeds the purified reactant 1 through another feed pipe. Under a certain temperature and pressure, the impurities in the crude silicon tetrafluoride gas react with...

Embodiment 1

[0096] A kind of purification method of silicon tetrafluoride, described purification method is as follows:

[0097] (1) supply silicon tetrafluoride crude product gas 200g to the reaction chamber of purifying device by feed pipe, supply purification reactant 1 carbonyl fluoride to reaction chamber by feed pipe, silicon tetrafluoride crude product gas and purification reactant 1 carry out Purification reaction, the reaction percentage 1 is 99%, the reaction temperature of the reaction chamber is 1999 ° C, the reaction pressure is 2 MPa, no dilution medium is used, no catalyst is used, and the obtained product is collected by a cold trap at -110 ° C to obtain purified tetrafluoroethylene silicon dioxide gas;

[0098] (2) the silicon tetrafluoride gas of the purification that step (1) obtains and purification reactant 2SiO 2 Carry out the purification reaction, the reaction percentage 2 is 20%, the reaction temperature in the reaction chamber is 1999°C, and the reaction pressur...

Embodiment 2

[0104] A kind of purification method of silicon tetrafluoride, described purification method is as follows:

[0105] (1) Reaction temperature is-199 DEG C, reaction pressure is-0.09MPa, reaction percentage 1 is 0.0001%, all the other are with embodiment 1 step (1).

[0106] (2) Purify by freezing and vacuuming, and the rest are the same as step (2) in Example 1.

[0107] The silicon tetrafluoride refined gas is tested and analyzed, and it can be seen that:

[0108] SiF 4 The purity of ≥99.9995%;

[0109] Impurities and content: (SiF 3 ) 2 O≤0.1ppm, CH 4 ≤0.1ppm, C 2 h 6 ≤0.1ppm, C 3 h 8 ≤0.1ppm, C 2 h 2 ≤0.1ppm, C 2 h 4 ≤0.1ppm, CO≤0.1ppm, H 2 ≤0.1ppm, B≤0.1ppm, P≤0.1ppm, As≤0.1ppm, Se≤0.1ppm, H 2 S≤0.1ppm, SO 2 ≤0.1ppm, N 2 O ≤ 0.1ppm, each metal ≤ 0.1ppm, O 2 ≤0.5ppm, N 2 ≤1ppm, CO 2 ≤1ppm, HF≤0.1ppm and HCl≤0.1ppm, other impurities were not detected;

[0110] The metals are: lithium, beryllium, sodium, magnesium, aluminum, potassium, calcium, titanium, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com