A kind of environment-friendly gas-sensitive coating for volatile acid and preparation method thereof

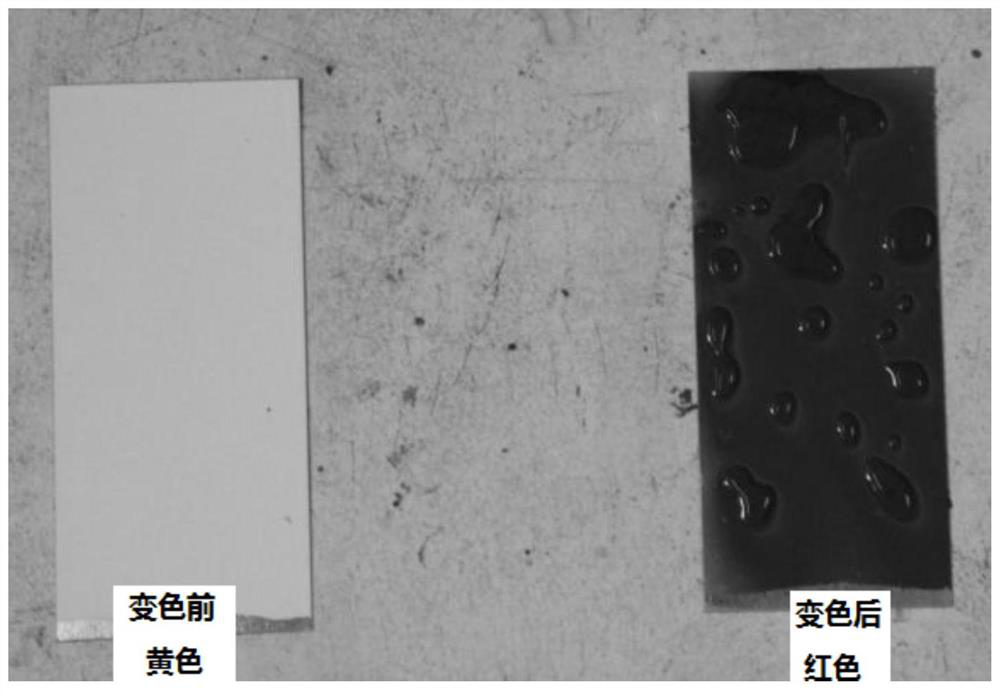

A volatile and environmentally friendly technology, applied in epoxy resin coatings, polyester coatings, chemical instruments and methods, etc., can solve the problems of inconspicuous discoloration, dependence on imports, long discoloration time, etc., to achieve obvious discoloration and wide application Wide, color changing reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

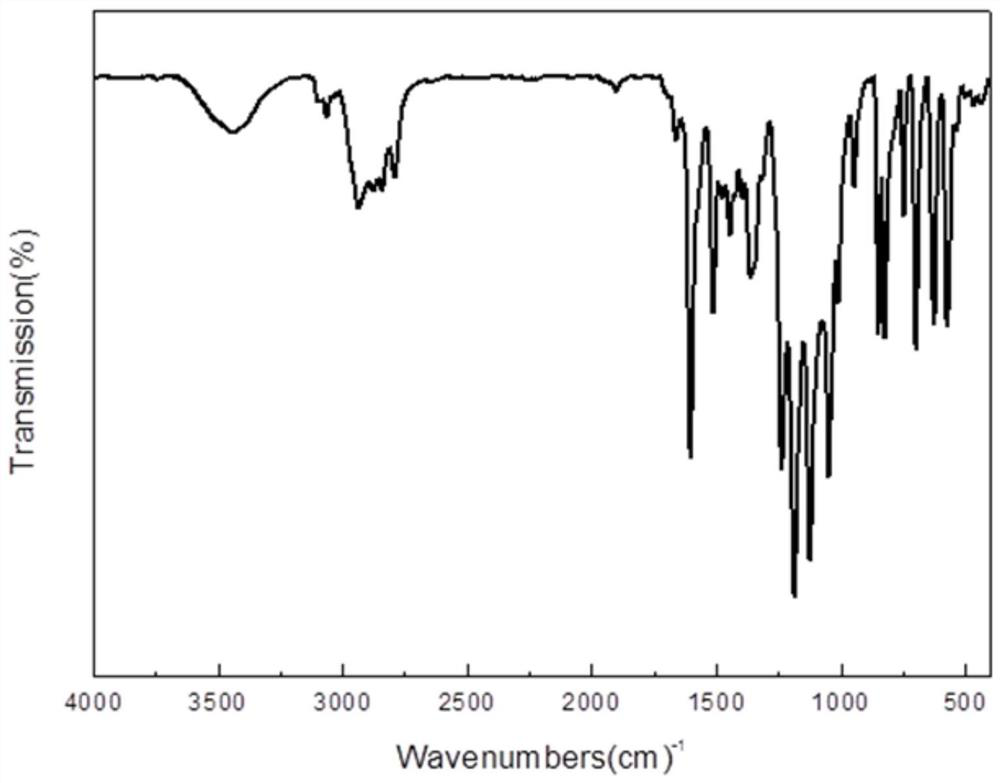

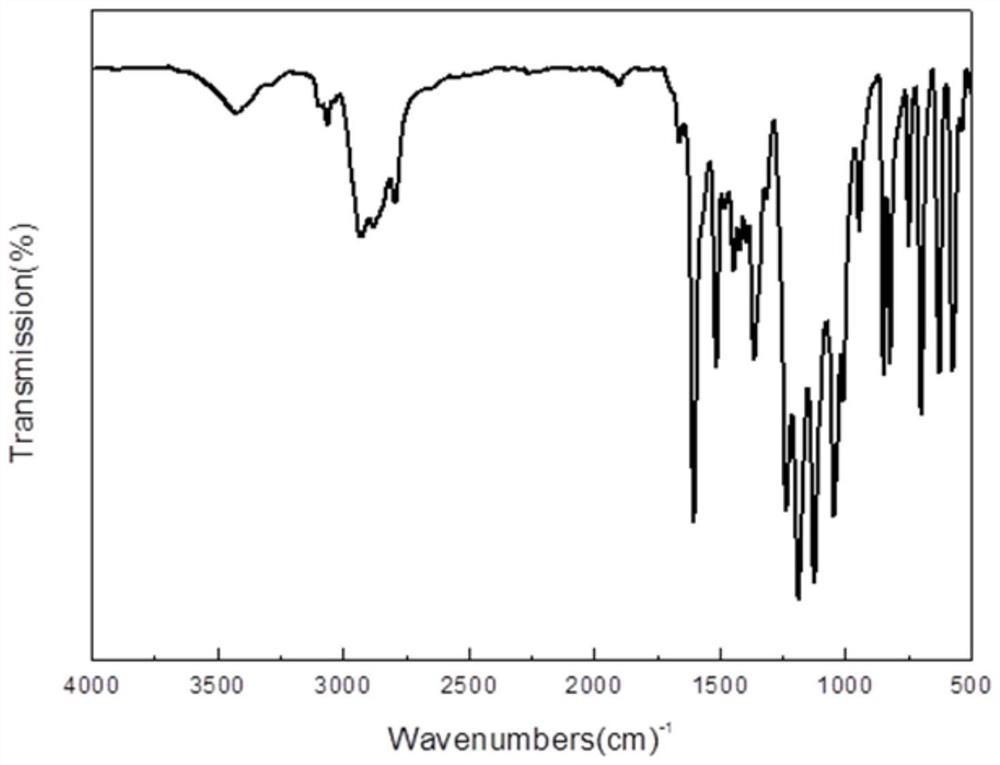

[0013] Technical scheme of the present invention is as follows:

[0014] An environmentally friendly gas-sensitive coating for volatile acids, comprising the following components by mass:

[0015] 50-100 parts of strong acid-resistant resin, 1-30 parts of special color-changing agent A1-30 parts, 0.5-5 parts of auxiliary color-changing component, 0-20 parts of filler, 0-20 parts of auxiliary agent, 0-300 parts of solvent;

[0016] Described special discoloration agent A is the substance obtained after compound B treats white carbon black;

[0017] The compound B has the following structural characteristics:

[0018]

[0019] Among them: R' is a variety of organic groups that act as bridges to connect the benzene ring to the silicon atom; it is further preferably an alkylene group, more preferably a C1-C8 alkylene group, preferably a methylene group, an ethylene group or propylene;

[0020] R" is a variety of organic groups that can leave with the HOR" structure; more pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com