Method for separating trifluoroethylene in tetrafluoroethylene production

A technology of trifluoroethylene and tetrafluoroethylene, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problem of chemical corrosion resistance of polymers, decline in dielectric properties, affecting polymer properties, and no treatment Methods and other issues, to improve the phenomenon of random discharge of trifluoroethylene, to achieve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

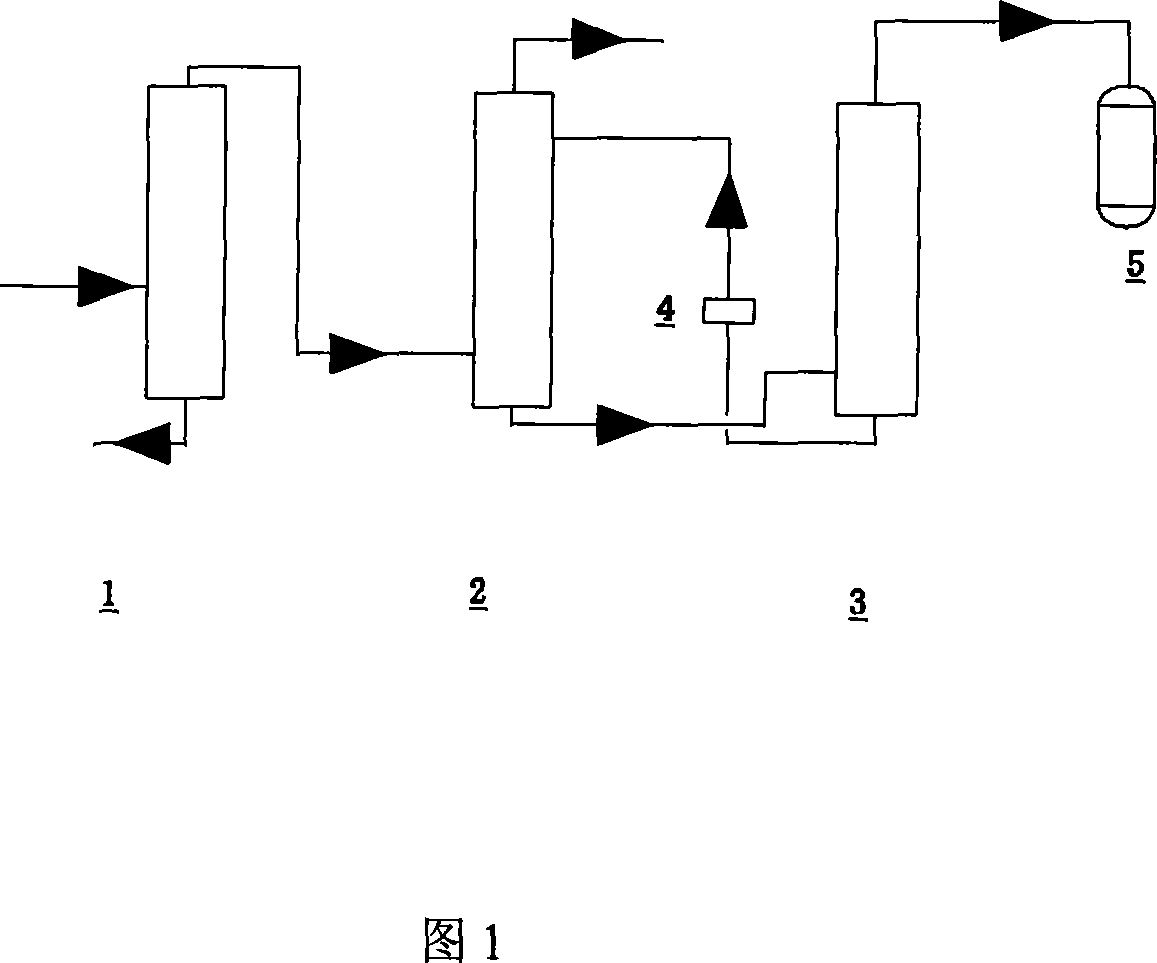

[0022] As shown in Figure 1, this device is implemented on a 3000-ton tetrafluoroethylene production device. This process is located behind the tetrafluoroethylene recovery tower, and the material gas enters tower 1 from the top of the tetrafluoroethylene recovery tower. The temperature at the top of tower 1 is - 15~+15℃, the temperature of the tower kettle is 10~50℃, and the liquid-gas ratio is 3~20:1; through the separation of tower 1, more than 90% of tetrafluoroethylene and trifluoroethylene in the material gas are separated, and two Useful components such as fluorochloromethane are returned to the original system from the tower kettle;

[0023] Trifluoroethylene and tetrafluoroethylene gather at the top of tower 1 and enter extraction tower 2 from the top of tower 1. Through the extraction of extraction tower 2, trifluoroethylene in the mixed gas of tetrafluoroethylene and trifluoroethylene is extracted. Ethylene molecules are non-polar molecules, and trifluoroethylene mo...

Embodiment 2

[0027] It is implemented on a 3,000-ton tetrafluoroethylene production plant. This process is located behind the tetrafluoroethylene recovery tower. The material gas enters tower 1 from the top of the tetrafluoroethylene recovery tower. The temperature at the top of tower 1 is -15~+15°C. The temperature is 10-50°C, and the liquid-gas ratio is 7-10:1; through the separation of tower 1, more than 90% of tetrafluoroethylene and trifluoroethylene in the material gas are separated, and useful components such as difluorochloromethane Point returns former system from tower still; Other is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com