Online environment monitoring system and method in fluorine chemical industry

A monitoring system and environment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unintuitive, unfavorable human protection, low degree of automation, etc., achieve good reproducibility and accuracy, avoid direct contact, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

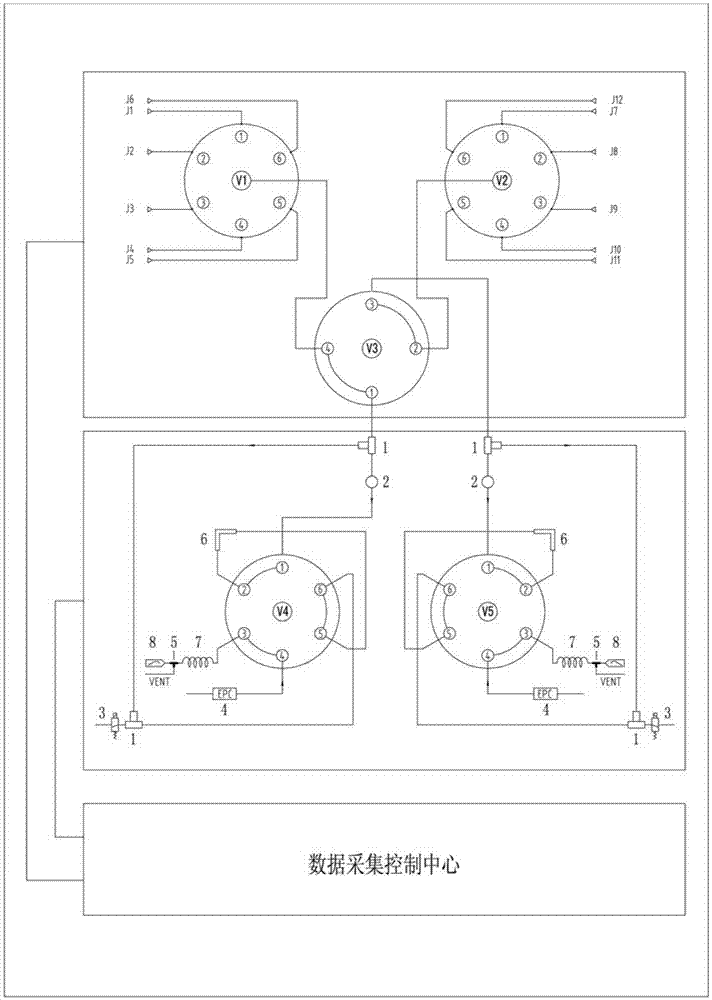

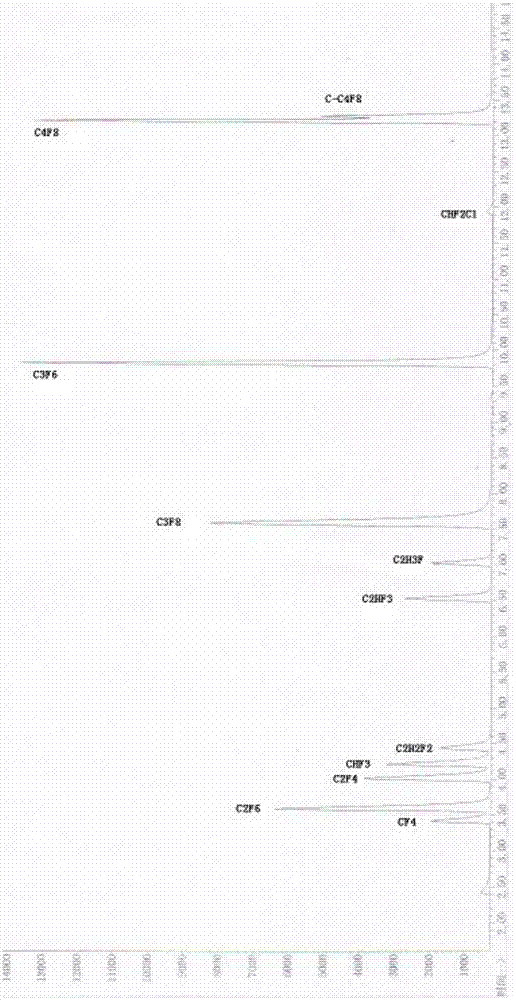

[0035] Example 1: Environmental online monitoring system for the fluorine chemical industry

[0036] The environmental online monitoring system of the fluorine chemical industry in this embodiment includes a sample collection unit, a multi-channel comprehensive analysis unit and a data collection control center, the sample collection unit is connected to the multi-channel comprehensive analysis unit through pipelines, and the multi-channel comprehensive analysis unit Connect to the data acquisition control center;

[0037] The online collection system includes a collection port, a bundle tube, and a multi-channel switching valve, the collection port is connected to the bundle tube, and a multi-channel switching valve is set on the pipeline formed by the bundle tube;

[0038] The multi-channel comprehensive analysis unit includes an adjustable distributor 5 electronic flowmeter 2, a silent oil-free diaphragm pump 3 and a gas chromatography-mass spectrometer, see figure 1 , is ...

Embodiment 2

[0043]In this example, a comparison is made with the mainstream material bundle tubes currently available on the market (the deactivated copper tubes are purchased from Agilent), and the results are listed in Table 1. The other components of the online monitoring device used are as described in Example 1, and the standard gas used is chlorodifluoromethane with a content of 5 ppb diluted with nitrogen.

[0044] Table 1 Main tube material

[0045] J1 J2 J3 J4 Tube material polyethylene PTFE Fusible tetrafluororesin Deactivated copper tube Tube length 160 meters 160 meters 160 meters 160 meters

[0046] According to the order of J1 to J5, cycle test 5 times, the results are as follows:

[0047] Table 2: Standard gas detection reproducibility

[0048]

[0049] From the experimental data in this embodiment, it can be known that the fluorine-containing resin bundle tube of polytetrafluoroethylene and fusible tetrafluororesin is select...

Embodiment 3

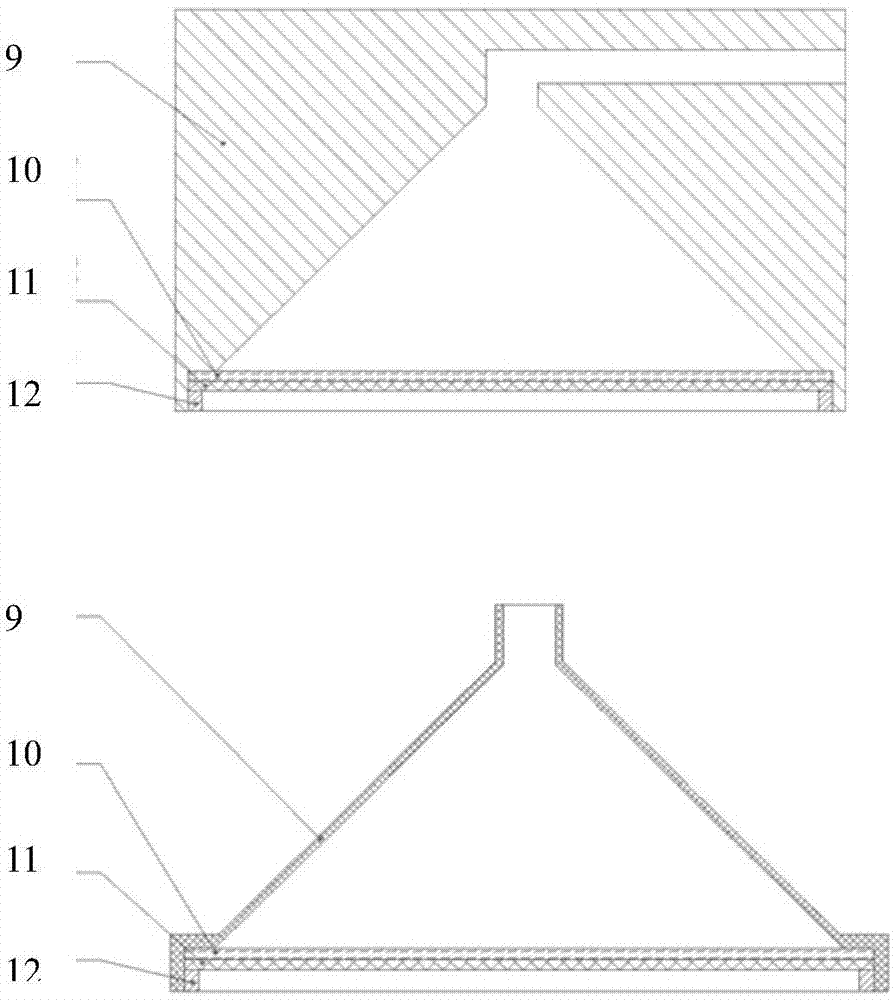

[0051] In this embodiment, an experiment is carried out on the importance of the polytetrafluoroethylene biaxially stretched gas permeable membrane treated with oil-repellent technology at the collection port as the filter membrane. The present embodiment has carried out two experiments: experiment pair three kinds of filter modes are compared, and adopt the system of embodiment 1 to the standard gas that the content of nitrogen dilution is 10ppb to carry out five repeated monitoring experiments, filter mode is as table 3, The experimental data are shown in Table 4; Experiment 2: The three filtering methods were monitored for three consecutive months in a machine room with heavy oil and gas, and the experimental results are shown in Table 5.

[0052] Table 3: List of filtering methods

[0053]

[0054] Table 4: Standard gas detection reproducibility

[0055]

[0056]

[0057] Table 5: List of on-site monitoring results

[0058]

[0059] From the experimental data...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com