Method for continuously extracting and recovering polytetrafluoroethylene dispersion resin

A polytetrafluoroethylene and dispersion resin technology, applied in the field of continuous extraction and recovery of polytetrafluoroethylene dispersion resin, can solve the problems of too many unit operations, unfavorable large-scale application, and the paraffin content index cannot meet the requirements, etc. High efficiency, effective reuse, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

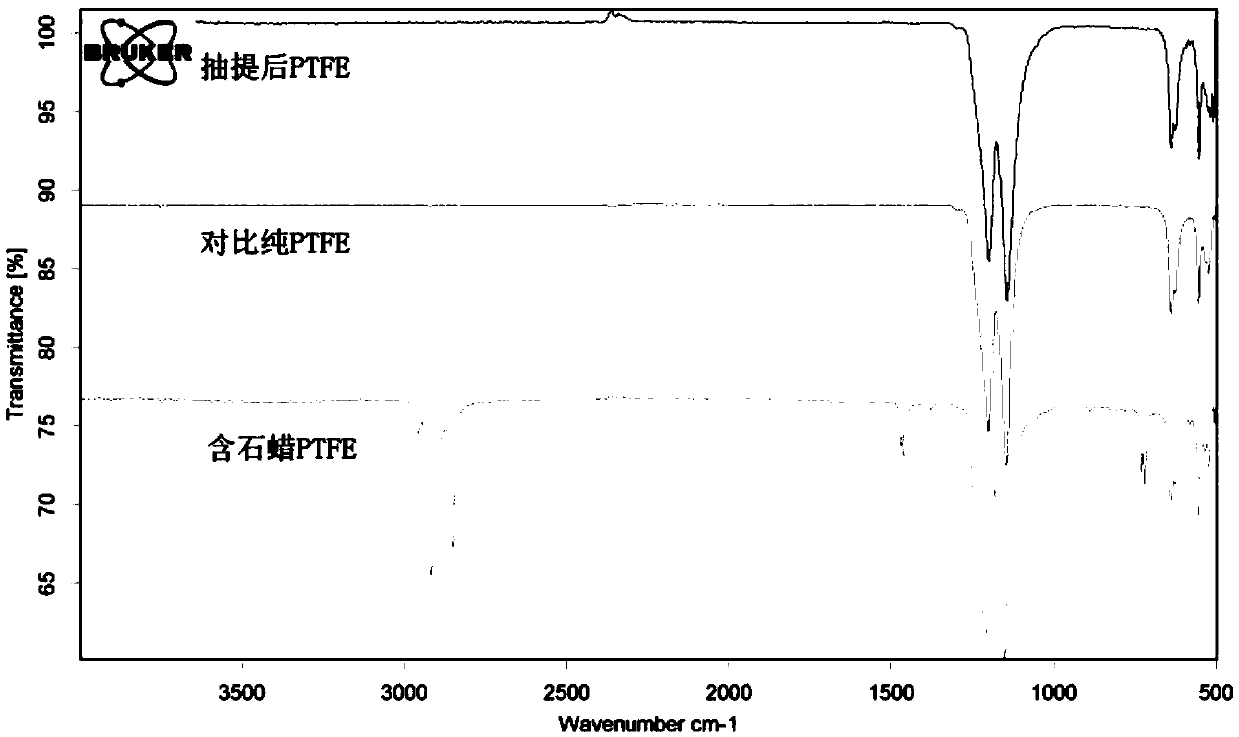

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for continuous extraction and recovery of tetrafluoroethylene dispersed resin, comprising the steps of:

[0040] 1) Soak the extraction sleeve in the extractor in chloroform for 8 hours; then put it in the temperature of 105°C and dry it for 2 hours, and accurately weigh 47.90g;

[0041] 2) the PTFE waste residue containing paraffin with a moisture content not higher than 10% is placed in the extraction sleeve, and accurately weighs 59.95g (the weight of the extraction sleeve after adding the PTFE waste residue, that is, the amount of PTFE waste residue is 12.05g); carefully put it into the Soxhlet extractor, and the extractor was kept warm with glass fiber cloth;

[0042] 3) Use chloroform as the organic solvent for the extraction treatment, connect the various parts of the extractor, connect the condensed water, and carry out the extraction treatment at a constant temperature of 62° C. for 5 hours;

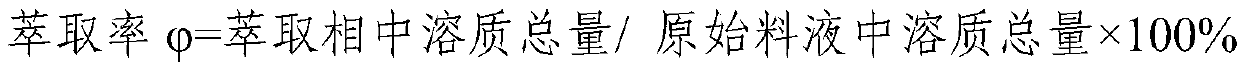

[0043]Wherein, the weight-to-volu...

Embodiment 2

[0049] This embodiment provides a method for continuous extraction and recovery of tetrafluoroethylene dispersed resin, the specific operation steps are the same as in Example 1, the difference is only in:

[0050] Step 2) in waxy PTFE waste residue add-on is 15.03g;

[0051] In step 4), "perform row extraction for 5 hours" is replaced by "perform extraction for 4 hours";

[0052] Finally, 6.97g of recycled PTFE was obtained, the wax content was 3.85% in the sample sent and the extraction rate was 96.3% in comprehensive analysis.

Embodiment 3

[0054] This embodiment provides a method for continuous extraction and recovery of tetrafluoroethylene dispersed resin, the specific operation steps are the same as in Example 1, the difference is only in:

[0055] Step 2) in waxy PTFE waste residue add-on is 14.36g;

[0056] In step 4), "perform row extraction for 5 hours" is replaced by "perform extraction for 6 hours";

[0057] Finally, 6.68g of recycled PTFE was obtained, and the wax content was 1.89% in the sample test, and the extraction rate of comprehensive analysis was 98.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com