A special thermoplastic composite material suitable for 3D printing and its preparation method

A composite material and 3D printing technology, applied in the direction of additive processing, etc., can solve problems such as poor adaptability, slow cooling speed, easy cooling deformation, etc., and achieve fast molding speed, fast cooling speed, and small molding shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ① 55 parts of polyphthalamide (PPA), 25 parts of Surlyn resin (Surlyn), 10 parts of ethylene-glycidyl methacrylate (E-GMA), 5 parts of nano-titanium dioxide, 5 parts of graphene, nucleation 0.5 part of dispersant, 0.8 part of dispersant, and 0.5 part of antioxidant were mixed in a high-speed mixer for 20 minutes at a speed of 300 to 1000 rpm to obtain material 1;

[0028] ②Put material 1 from the main feeding port into the parallel twin-screw extruder for granulation, the granulation temperature is 340°C, the screw speed is 400rpm, the water ring is used to granulate, and the cyclone separation is dried to obtain a special thermoplastic compound suitable for 3D printing. Material.

Embodiment 2

[0030] ① 65 parts of polyphthalamide (PPA), 10 parts of Surlyn resin (Surlyn), 5 parts of ethylene-glycidyl methacrylate (E-GMA), 10 parts of nano-titanium dioxide, 10 parts of graphene, nucleation 0.5 part of agent, 0.8 part of dispersant, and 0.5 part of antioxidant were mixed in a high-speed mixer for 20 minutes at a speed of 500 rpm to obtain material 1;

[0031] ②Put material 1 from the main feeding port into the parallel twin-screw extruder for granulation, the granulation temperature is 340°C, the screw speed is 400rpm, the water ring is used to granulate, and the cyclone separation is dried to obtain a special thermoplastic compound suitable for 3D printing. Material.

Embodiment 3

[0038] The performance test of embodiment 3 materials

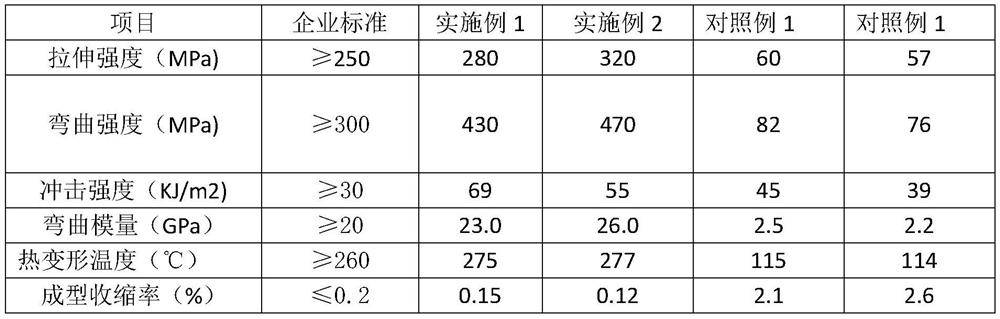

[0039] The special thermoplastic composite materials prepared in Examples 1-2, Comparative Examples 1 and 2 are divided into four groups, and each group of materials carries out the following performance tests according to the following national standards:

[0040] The national testing standards adopted are as follows:

[0041] Tensile performance test standard: GB1040-79;

[0042] Bend performance test standard: GB1042-79;

[0043] Impact performance test standard: GB1043-79;

[0044] Heat distortion temperature test standard: GB1634-79;

[0045] Plastic molding shrinkage test standard: ASTM D955.

[0046] The test results of the above materials are shown in the table below:

[0047]

[0048] From the above results, it can be seen that the special thermoplastic composite materials suitable for 3D printing prepared in Examples 1-2 have extremely high strength and impact toughness, and the thermal deformation tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com