Umbrella-shaped gas collecting structure

A tubular structure and umbrella-shaped technology, which is applied in the field of umbrella-shaped gas-collecting structures, can solve the problems of not being able to meet the needs of raw gas export, and achieve the effects of convenient manufacturing, installation and replacement, large gas conduction area, and fast and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

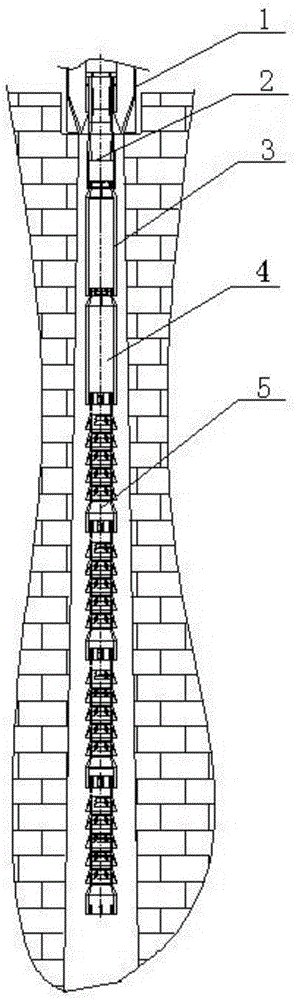

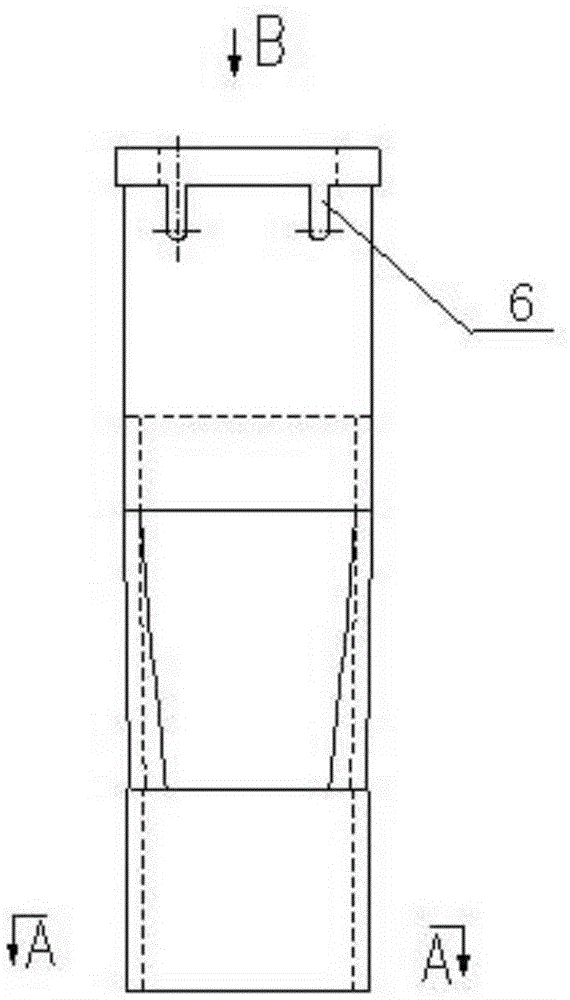

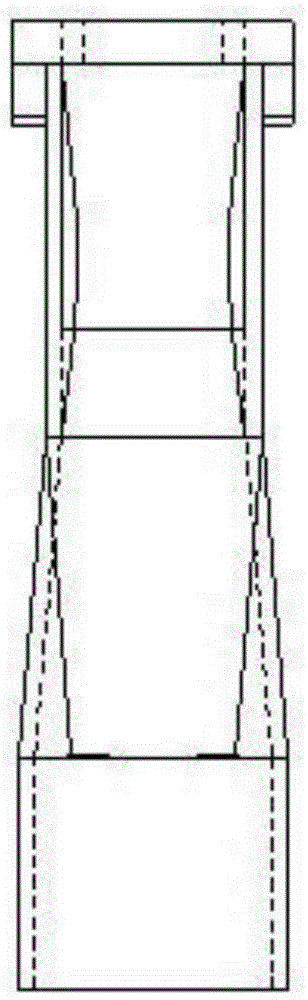

[0029] Such as figure 1 As shown, an umbrella-shaped gas-collecting structure of the present invention is installed in the carbonization chamber of an externally heated low-order pulverized coal retort furnace; it includes an upper tubular structure and a lower umbrella-shaped structure; the upper tubular structure is sequentially connected by the first section 2 from top to bottom , the middle section 3 and the last section 4, wherein the first section 2 is hung on the deep coal box 1, and its upper shape is adapted to the shape of the deep coal box 1; the first section 2, the middle section 3 and the last section 4 are fast The joint is connected, and the last section 4 is connected to the hook 9 on the upper part of the lower umbrella structure through the lifting lug 8; the lower umbrella structure is composed of several air-collecting umbrell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com