Sapphire tube black body cavity optical fiber temperature measurement device

An optical fiber temperature measurement and sapphire technology, which is used in measurement devices, thermometers, and heat measurement, etc., can solve problems such as complex optical signal processing devices, and achieve the effect of reducing interference, reducing the risk of deterioration, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

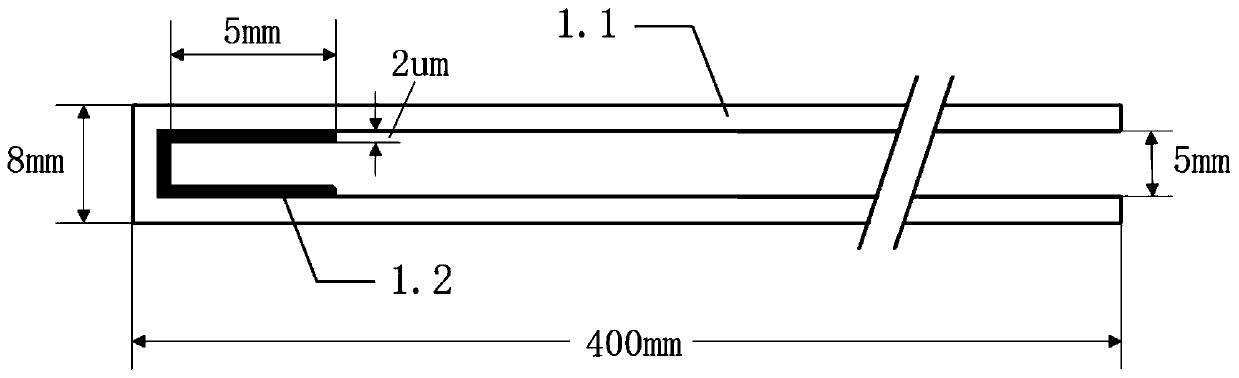

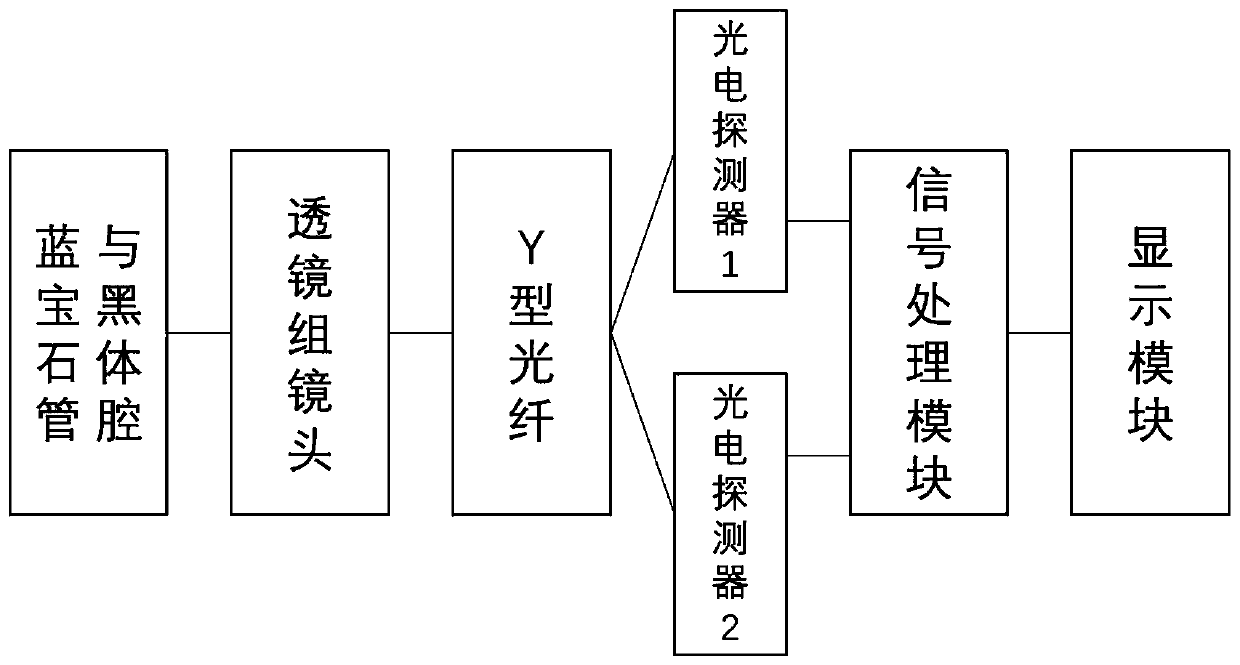

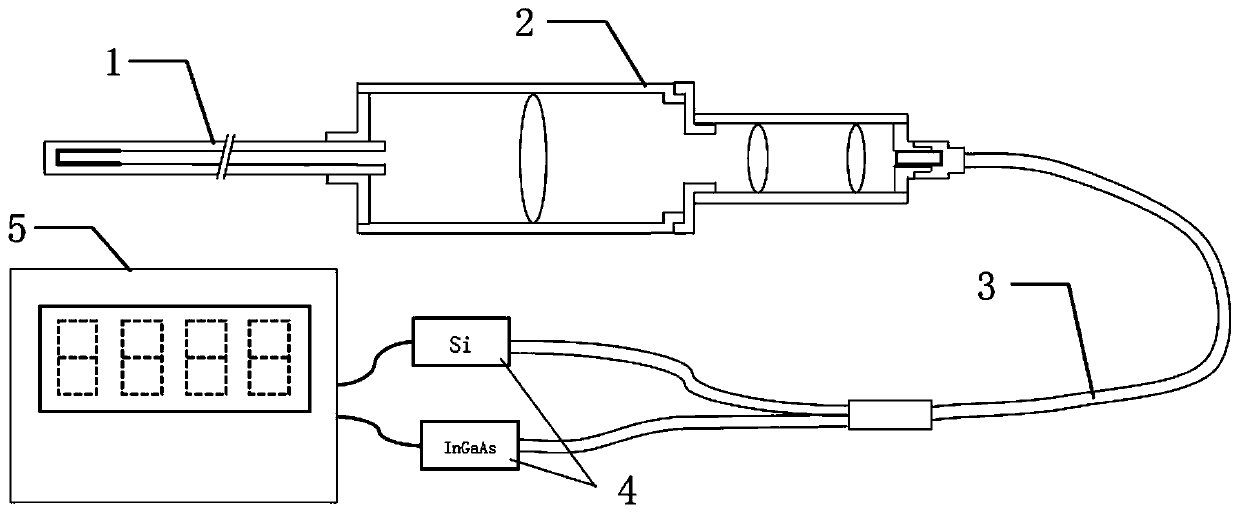

[0027] Such as figure 1 with figure 2 As shown, a sapphire tube blackbody cavity optical fiber temperature measuring device designed by the present invention includes an optical system and a circuit system. The optical system includes a sapphire tube 1 coated with a blackbody cavity at one end of the seal, a lens group lens 2 and a Y-shaped energy transmission fiber 3. Among them, the standard single crystal sapphire tube 1.1 specification is (inner diameter 5mm*outer diameter 8mm*length 400mm), one end is the sealing end; use vacuum magnetron sputtering coating technology to coat a layer of 1-2μm thick and 5mm long Al on the bottom of the sealing end of the sapphire tube and the adjacent wall 2 o 3 Coating, that is to form a black body cavity 1.2; lens group lens 2 coupling wavelength range 350nm ~ 2000nm, Y-shaped energy transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com