Electrocatalytic reduction combined electrode and preparation method and application thereof

A composite electrode, electrocatalysis technology, applied in chemical instruments and methods, reduced water/sewage treatment, water pollutants, etc., can solve the problems of poor conductivity, high specific surface area, hydrophobicity, etc., and achieve enhanced conductivity and high specific surface area. , the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of composite electrode of the present invention comprises the following steps:

[0032] (1) Graphite felt (GF) pretreatment: Graphite felt is ultrasonically washed with acetone and methanol for 20 minutes each to remove surface organic matter, and then washed with distilled water; then immersed in a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:1 for 1 hour , for corrosion roughening treatment;

[0033] (2) Preparation of multi-walled carbon nanotube (MWCNTs) suspension: add 0.1-0.5g MWCNTs to a certain concentration of hexadecyltrimethylammonium bromide solution and perform full ultrasound to prepare a reaction solution;

[0034] (3) Preparation of MWCNTs / GF electrode: Take the pretreated GF in step (1) as the cathode, and the titanium plate as the anode, put them into the reaction solution obtained in step (2), and conduct electrodeposition with a current of 5-30mA for 30min. Obtain MWCNTs / GF...

Embodiment 1

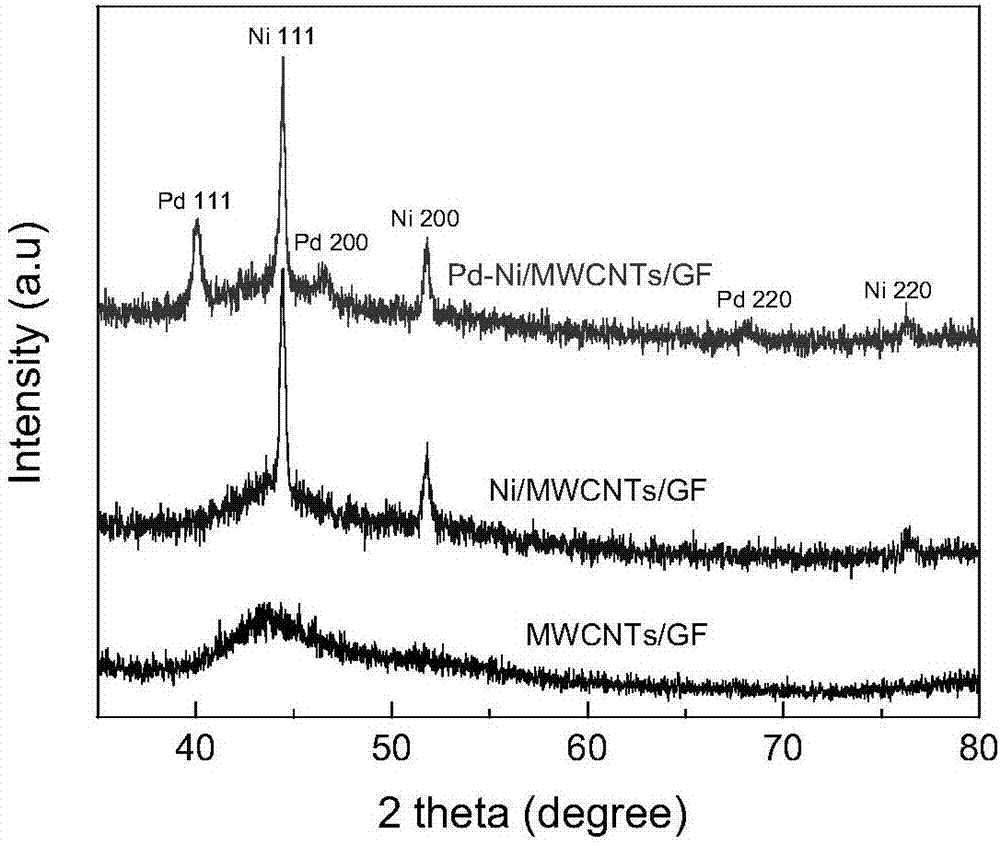

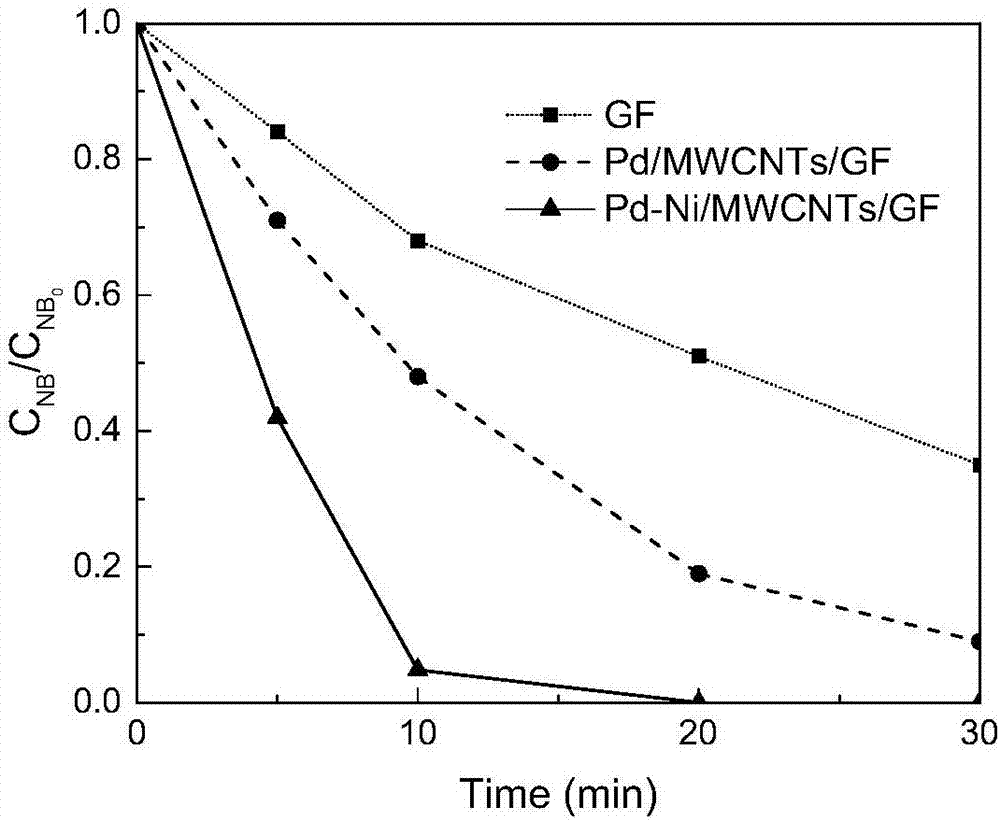

[0040] Example 1 (Pd-Ni / MWCNTs / GF electrode)

[0041] (1) Graphite felt (GF) pretreatment: GF was washed with acetone and methanol for 20 minutes to remove surface organic matter, and then washed with distilled water. Then immerse in a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:1 for 1 hour to carry out corrosion roughening treatment;

[0042] (2) Configuration of multi-walled carbon nanotube (MWCNTs) suspension: add 0.1-0.5g MWCNTs to a certain concentration of hexadecyltrimethylammonium bromide solution and perform sufficient ultrasonication to obtain a reaction solution;

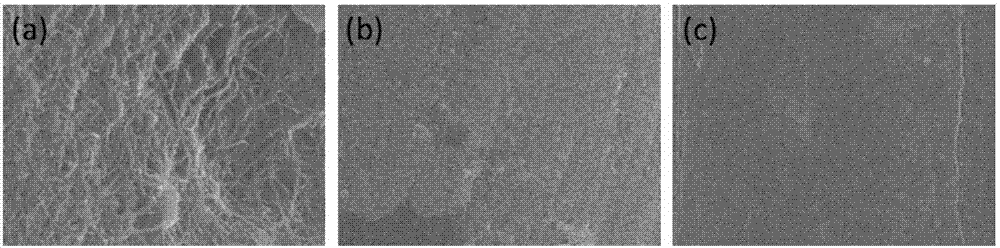

[0043] (3) Preparation of MWCNTs / GF electrode: Take the GF treated in step (1) as the cathode, and the titanium plate electrode as the anode, put it into the MWCNTs suspension obtained in step (2), and conduct electrodeposition at 5-30mA for 30min , to get MWCNTs / GF electrode (scanning electron microscope photo see figure 1 ).

[0044] (4) Configura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com