FEP fluorine color master batch and processing technique thereof

A processing technology and color masterbatch technology, which is applied in the field of fluoroplastic color masterbatch, can solve the problems of poor corrosion resistance, poor electrical insulation performance, and short service life, and achieve long service life, large insulation resistance, and excellent electrical insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

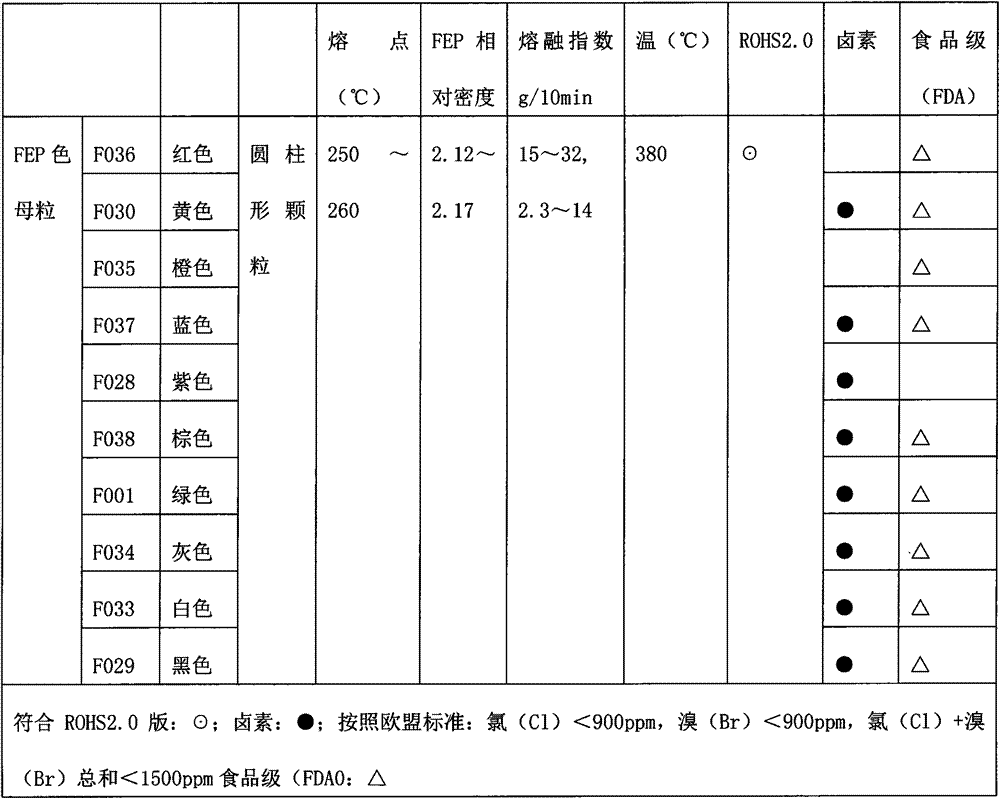

[0028] The FEP fluorine masterbatch of the present invention can be made from the raw materials of the following weight ratio:

[0029] 65% to 85% FEP;

[0030] 8%~25% high temperature pigment;

[0031] 3% to 6% dispersant;

[0032] 0.1% to 2% processing aids.

[0033] The present invention also discloses a processing technique for preparing the above-mentioned FEP fluorine masterbatch, comprising the following steps:

[0034] (1) Ingredients: 65% to 85% of FEP, 8% to 25% of high-temperature pigments, 3% to 6% of dispersants and 0.1% to 2% of processing aids are weighed according to the weight ratio;

[0035] (2) extrusion molding; mixing the ingredients weighed in step (1) into a twin-screw extruder for mixing and plasticization, and carrying out vacuum moisture treatment, and finally extrusion molding;

[0036] (3) cooling; the product extruded in step (2) is rapidly cooled, so that the product after mixing is rapidly crystallized, the surface temperature is reduced, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com