Preparation method of superfine polytetrafluoroethylene fiber

A technology of polytetrafluoroethylene and polyvinyl alcohol, which is applied in fiber processing, spinning solution preparation, textiles and papermaking, etc. It can solve the problems of inability to produce ultrafine polytetrafluoroethylene fibers and achieve high uniformity of fineness , High temperature and corrosion resistance, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

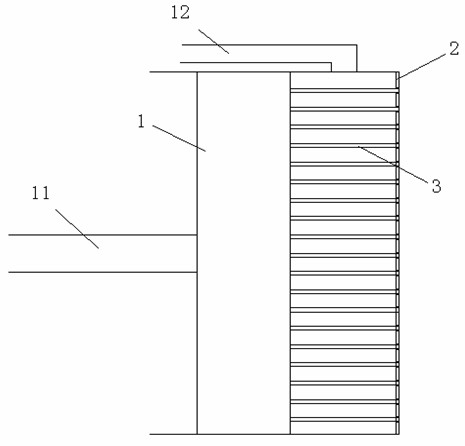

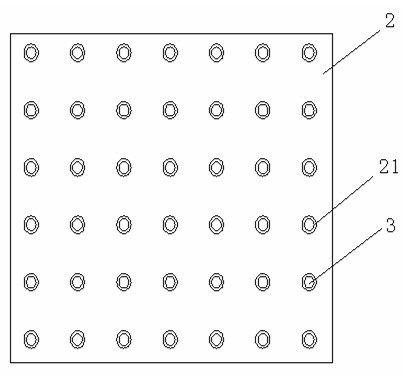

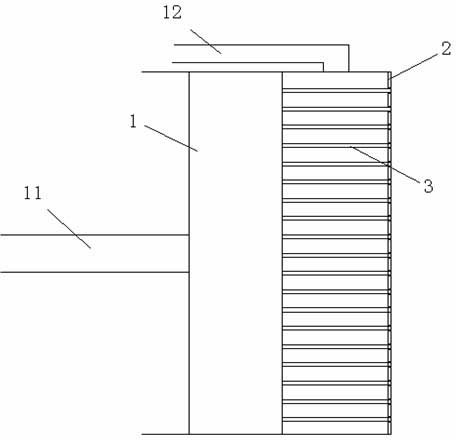

Image

Examples

Embodiment 1

[0027] A preparation method of the ultrafine polytetrafluoroethylene fiber of the present invention, the steps are as follows:

[0028] Preparation of spinning solution 1

[0029] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 9.

[0030] Preparation of spinning solution 2

[0031] Use polyvinyl alcohol (2488, 1788, etc.) with an alcoholysis degree of 88% to prepare a 15% polyvinyl alcohol solution in cold water, add sulfuric acid to make the pH value at 4, add boric acid at a ratio of 1:100 to facilitate its formation of gel , You can add an appropriate amount of defoamer according to the stirring speed, and the defoamer is simethicone. Static vacuum defoaming for 12 hours for later use.

[0032] Prepare supersaturated coagulation bath

[0033] Dissolve sodium sulfate (glauber's salt) in warm water at 45 degrees Celsius to form a supersaturated solution with cry...

Embodiment 2

[0043] Another kind of preparation method of ultrafine polytetrafluoroethylene fiber, the concrete steps of this method are as follows:

[0044] Preparation of spinning solution 1

[0045] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 8;

[0046] Preparation of spinning solution 2

[0047] Use alcoholysis degree of 70% polyvinyl alcohol to prepare 10%% polyvinyl alcohol solution in cold water, add sulfuric acid to make the pH value at 3, and add boric acid at a ratio of 1:100, stir to make it form a gel, and then Static vacuum degassing for 10 hours for standby;

[0048] Prepare supersaturated coagulation bath

[0049] Sodium sulfate is dissolved in warm water at 40 degrees Celsius to form a supersaturated solution with crystals, and caustic soda is added to adjust the pH value to 12;

[0050] spinning

[0051] Spinning liquid 1 and spinning liquid 2 pass throu...

Embodiment 3

[0058] Another kind of preparation method of ultrafine polytetrafluoroethylene fiber, the concrete steps of this method are as follows:

[0059] Preparation of spinning solution 1

[0060] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 10;

[0061] Preparation of spinning solution 2

[0062] Prepare a 120% polyvinyl alcohol solution in cold water with polyvinyl alcohol with a degree of alcoholysis of 90%, add sulfuric acid to make the pH value at 5, and add boric acid at a ratio of 1:100, stir to make it form a gel, and then stand still Vacuum degassing for 15 hours for standby;

[0063] Prepare supersaturated coagulation bath

[0064] Sodium sulfate is dissolved in warm water at 50 degrees Celsius to form a supersaturated solution with crystals, and caustic soda is added to adjust the pH value to 14;

[0065] spinning

[0066] Spinning liquid 1 and spinning liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com