Device and method for preparing titanium-containing superalloy hollow steel ingot by electroslag remelting

A technology of electroslag remelting and high-temperature alloys, which is applied in the field of iron and steel metallurgy, can solve problems such as inclusions, alloy composition steel ingot surface quality control bottlenecks, segregation, etc., to improve internal quality and surface quality, smooth inner and outer surface quality, and reduce core The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

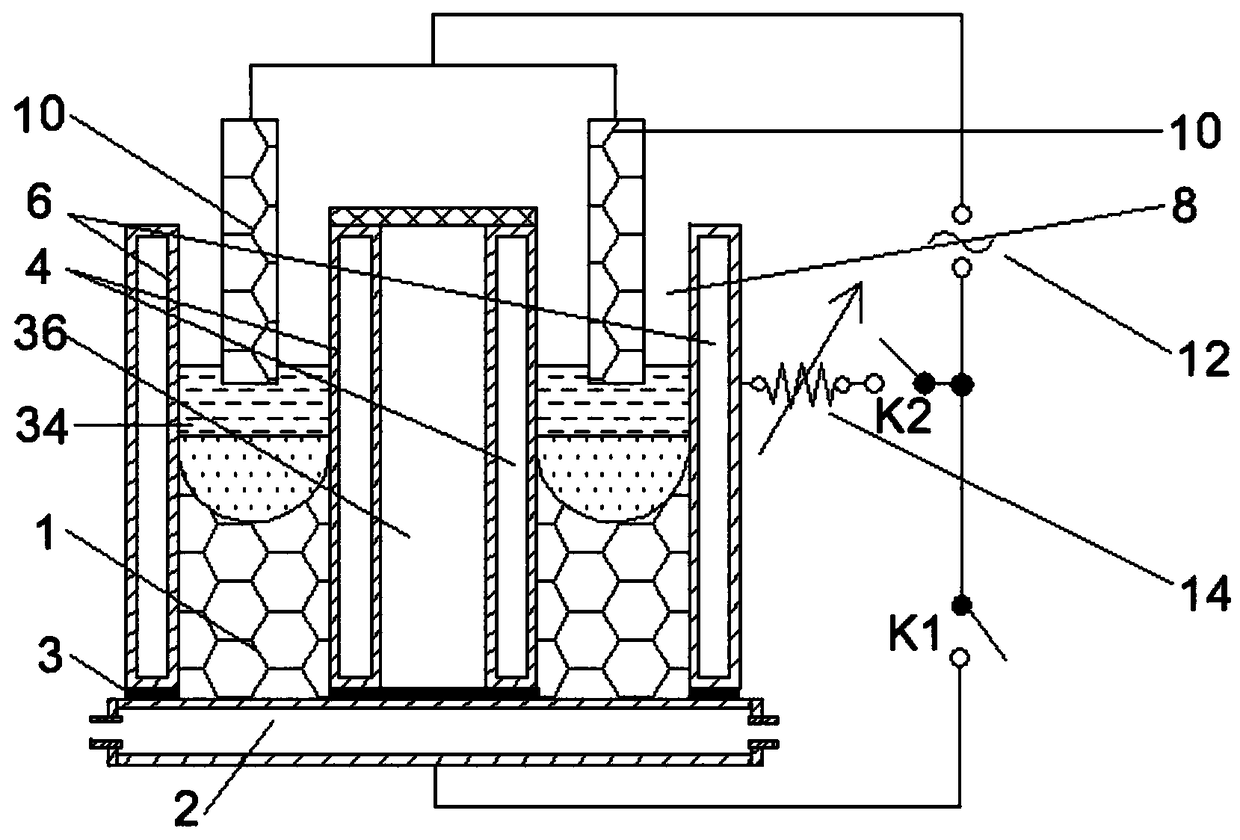

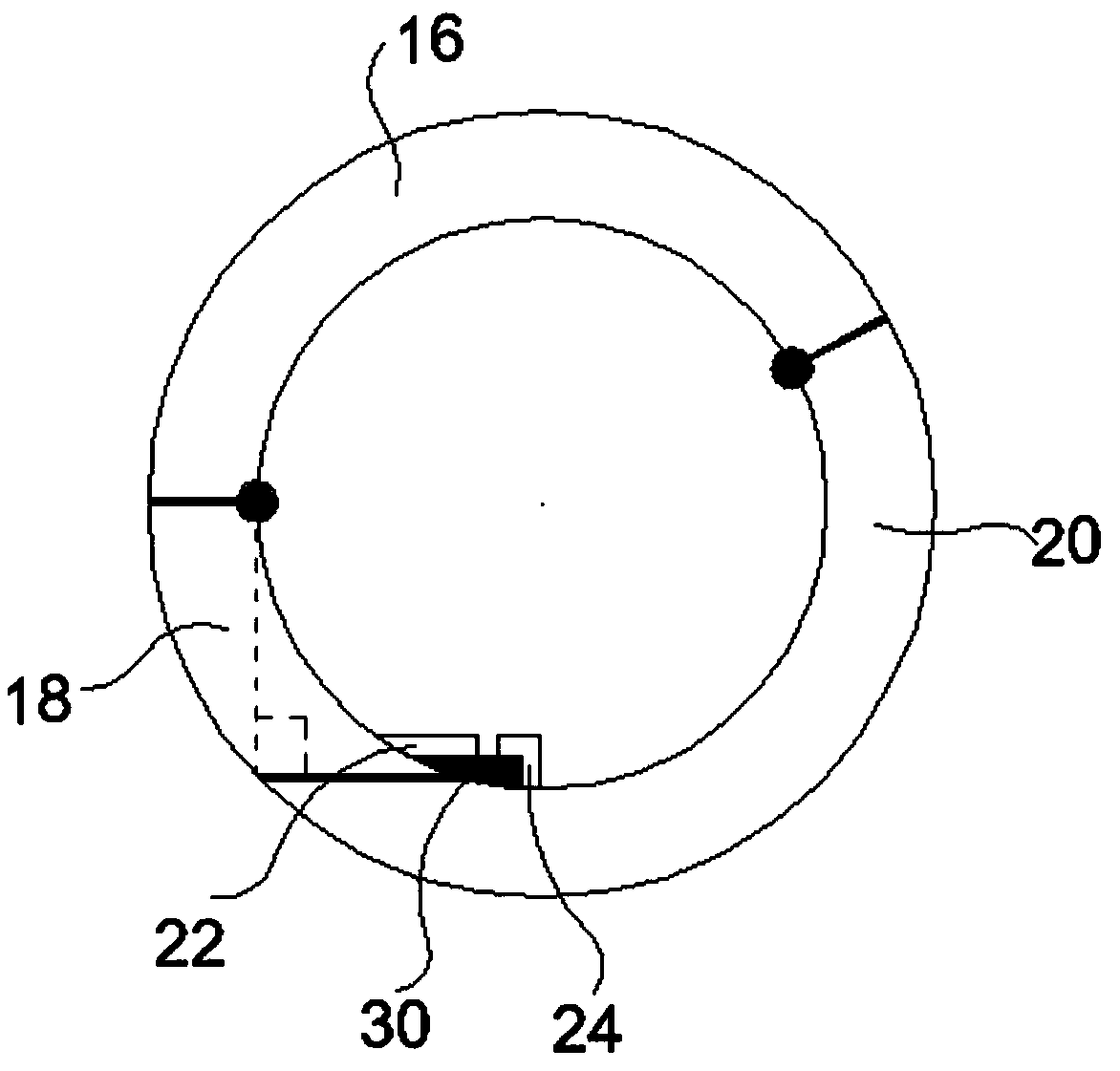

[0043] Such as Figure 1-2 As shown, this embodiment discloses a device for preparing a titanium-containing superalloy hollow steel ingot by electroslag remelting, including an electroslag remelting furnace 2, an inner mold 4, an outer mold 6 and a power supply system. The above-mentioned inner mold 4 and outer mold 6 are all installed on the electroslag remelting furnace 2, corresponding to the hollow steel ingot (containing titanium superalloy) of hollow tubular structure, the above-mentioned inner mold 4 and outer mold 6 are all preferably Hollow cylindrical body structure, the inner crystallizer 4 and the outer mold 6 are arranged coaxially inside and outside, and an annular pouring cavity 8 is formed between them; Describes the electroslag remelting smelting in the cavity, and cooling to form titanium-containing superalloy parts (hollow steel ingots). The use of internal and external combined crystallizers can abandon the ingot extraction link of the traditional ingot-pu...

Embodiment 2

[0058] This example discloses a method for preparing a titanium-containing superalloy by electroslag remelting. The device in Example 1 is used to prepare GH738. The chemical composition of the consumable electrode is shown in Table 1.

[0059] Table 1 Chemical composition of superalloy GH738 consumable electrode

[0060] Grade

C

Cr

co

Mo

Al

Ti

Ni

GH738

0.05

19.2

13.5

4.2

1.4

3.1

Bal

[0061] It includes the following steps:

[0062] (1) Prepare GH738 superalloy consumable electrode groups, 4 electrode groups on the left side and 4 electrode groups on the right side;

[0063] (2) Use the following mass percentage proportioning slag: CaF 2 :59%, CaO:18%, Al 2 o 3 :18%, TiO 2 : 5% of the slag is placed in the slag melting furnace, insert graphite electrodes for slag melting, after the end, pour the high-temperature liquid slag into the annular pouring cavity, insert the self-consumable electrode group, and ...

Embodiment 3

[0070] Using the electroslag remelting device of the above-mentioned embodiment 1 to prepare a titanium-containing superalloy hollow ingot, the following method was adopted to prepare Inconel 740, and the chemical composition of the consumable electrode is shown in Table 3.

[0071] Table 3 Chemical composition of superalloy Inconel 740 consumable electrode

[0072] Grade

C

Cr

co

Nb

Si

Al

Ti

Ni

Inconel740

0.03

25

20

2

0.5

0.9

1.8

Bal

[0073] It specifically includes the following steps:

[0074] (1) Prepare Inconel 740 superalloy consumable electrode groups, with 4 electrodes on the left and 4 electrodes on the right;

[0075] (2) Use the following mass percentage proportioning slag: CaF 2 :59%, CaO:18%, Al 2 o 3 :18%, TiO 2 : 5% of the slag is placed in the slag melting furnace, and graphite electrodes are inserted for slag melting. After the end, the high temperature liquid slag is poured into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com