Flat coke receiving car used for reducing coke burning loss and provided with dust removal device

A dust removal device and the technology of flat-joint coke cars, which are applied in the field of flat-joint coke cars, can solve the problems of low operating costs, high operating costs, and large investment in dust removal, etc., and achieve the effect of reducing investment costs and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

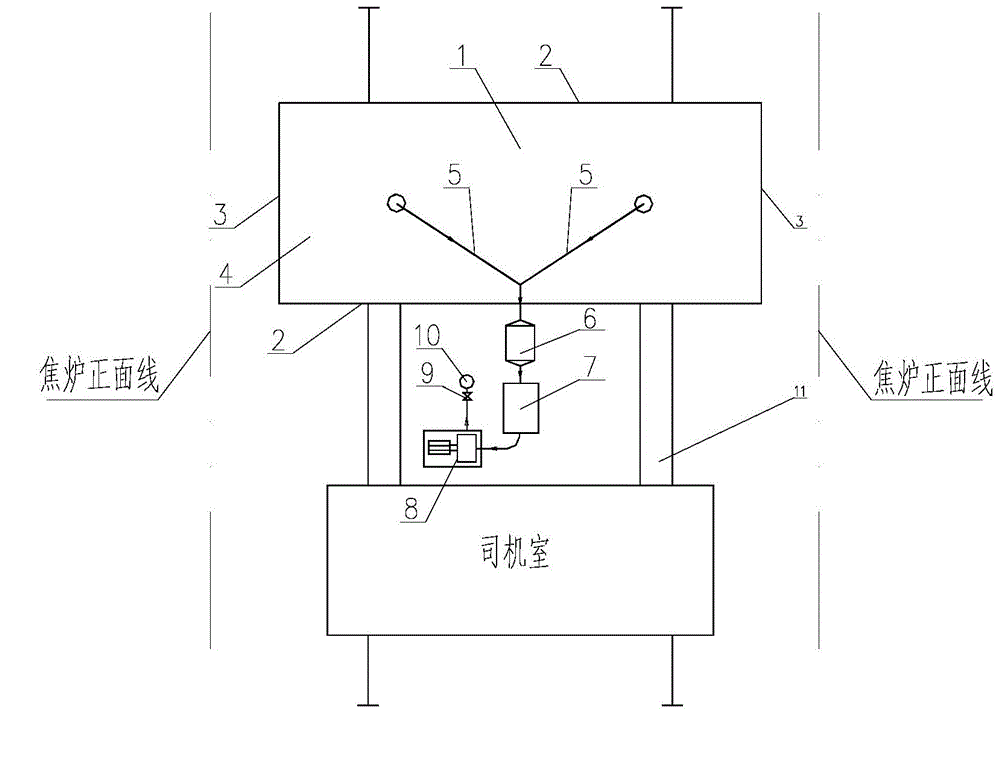

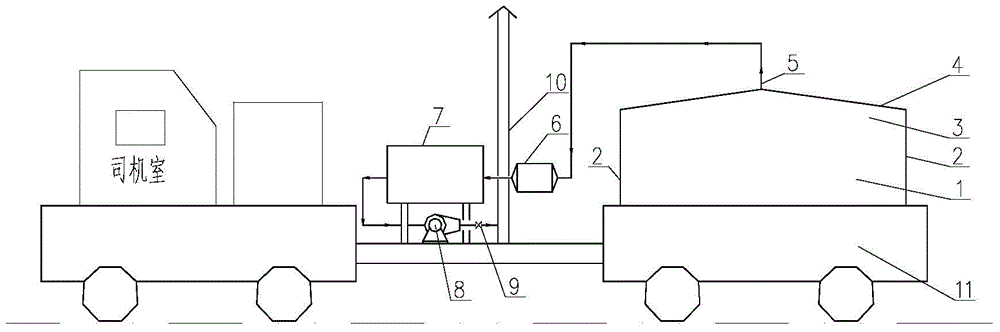

[0014] Such as figure 1 with figure 2 As shown, the butt joint coke car with reduced coke burning loss and dust removal device in this embodiment includes a dust removal pipeline 5, a filter 6, a dust collector 7, an induced draft fan 8, a flue gas valve 9, an exhaust cylinder 10 and a connecting rod. Coke car 11, wherein: it also includes a coke slot 1 composed of a coke slot top plate 4, two fixed baffles 2 and two movable baffles 3, and the two fixed baffles 2 are arranged at the front and back of the coke slot 1 On both sides, two movable baffles 3 are arranged on the left and right sides of the coke receiving groove 1 and can be opened by a hydraulic mechanism to facilitate coke receiving or coking out, and the top plate 4 of the coke receiving groove is arranged on two fixed baffles 2 and two movable A closed coke receiving groove 1 is formed on the top of the baffle plate 3, which prevents the coke in the coke receiving groove from contacting with the air, and reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com