High- and low-temperature-resistant aluminum alloy for gear box of motor train unit and preparation method therefor

A high and low temperature resistance, aluminum alloy technology, applied in the field of aluminum alloys, can solve the problems of poor high and low temperature resistance, poor strength, etc., to achieve the effect of improving high and low temperature performance, improving flexural resistance and strength, improving plasticity and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

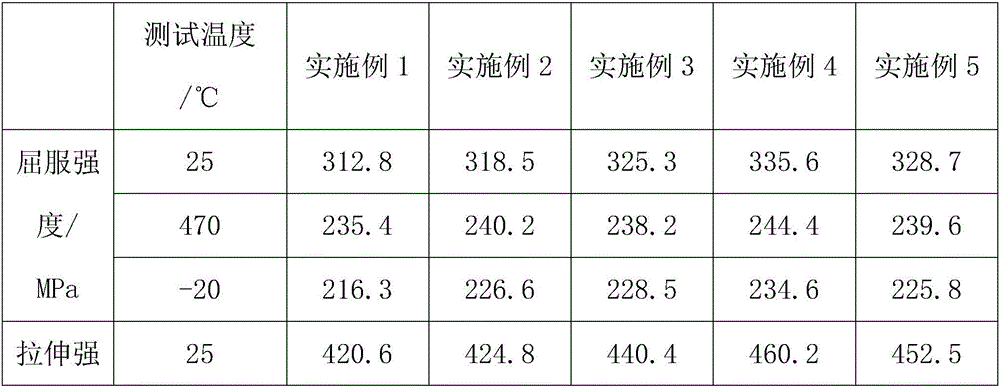

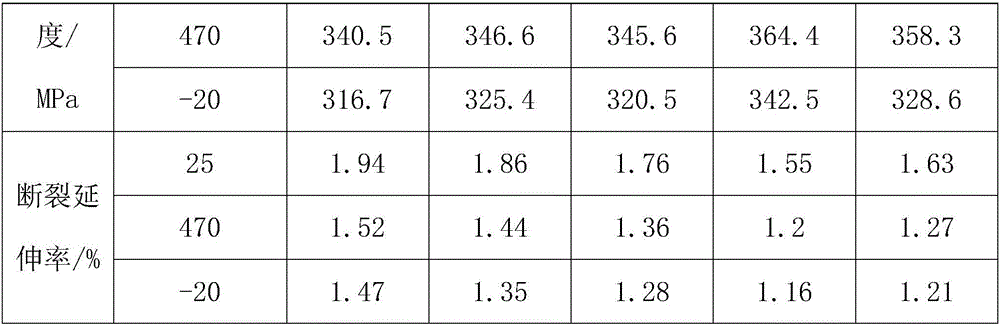

Examples

Embodiment 1

[0021] A high and low temperature resistant aluminum alloy for the gear box of an EMU, the composition of the aluminum alloy includes the following components by weight percentage: Mg: 0.6%, Cu: 1.1%, Zn: 0.08%, Si: 7.2%, B: 0.07 %, Ti: 0.25%, Ni: 0.01%, Nd: 0.08%, Mn: 0.2%, Pt: 0.03%, Cd: 0.005%, Sn: 0.018%, Cr: 0.01%, Ge: 0.024%, Nb: 0.035 %, Mo: 0.062%, Hf: 0.048%, the single content of other impurity elements ≤0.05%, the total content of other impurity elements ≤0.15%, and the balance is Al.

[0022] The preparation method of the high and low temperature resistant aluminum alloy for the motor train gear box proposed by the present invention, the specific steps are as follows:

[0023] S1. Melting: Preheat the melting furnace for 25 minutes, put pure Al into the furnace, heat to 735°C, keep the temperature for 30 minutes after the pure Al is melted, then add other raw materials in order of melting point from low to high, and stir After it is completely melted, lower the te...

Embodiment 2

[0028] A high and low temperature resistant aluminum alloy for the gearbox of an EMU, the composition of the aluminum alloy includes the following components by weight percentage: Mg: 0.75%, Cu: 0.96%, Zn: 0.14%, Si: 6.72%, B: 0.096 %, Ti: 0.225%, Ni: 0.02%, Nd: 0.064%, Mn: 0.37%, Pt: 0.025%, Cd: 0.008%, Sn: 0.015%, Cr: 0.022%, Ge: 0.021%, Nb: 0.042 %, Mo: 0.051%, Hf: 0.052%, the single content of other impurity elements ≤0.05%, the total content of other impurity elements ≤0.15%, and the balance is Al.

[0029] The preparation method of the high and low temperature resistant aluminum alloy for the motor train gear box proposed by the present invention, the specific steps are as follows:

[0030] S1. Melting: Preheat the melting furnace for 28 minutes, put pure Al into the furnace, heat to 730°C, keep the temperature for 38 minutes after the pure Al is melted, and then add other raw materials in order of melting point from low to high, in the stirring state After it is comple...

Embodiment 3

[0038] A high and low temperature resistant aluminum alloy for the gearbox of an EMU, the composition of the aluminum alloy includes the following components by weight percentage: Mg: 0.9%, Cu: 0.86%, Zn: 0.2%, Si: 6.4%, B: 0.13 %, Ti: 0.16%, Ni: 0.04%, Nd: 0.056%, Mn: 0.58%, Pt: 0.018%, Cd: 0.011%, Sn: 0.011%, Cr: 0.025%, Ge: 0.016%, Nb: 0.054 %, Mo: 0.042%, Hf: 0.066%, the individual content of other impurity elements is ≤0.05%, the total content of other impurity elements is ≤0.15%, and the balance is Al.

[0039] The preparation method of the high and low temperature resistant aluminum alloy for the motor train gear box proposed by the present invention, the specific steps are as follows:

[0040] S1. Melting: preheat the melting furnace for 27 minutes, put pure Al into the furnace, heat to 720°C, keep the temperature for 35 minutes after the pure Al is melted, and then add other raw materials in order of melting point from low to high, in the stirring state After it is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com