Aluminum-scandium alloy target material, preparation method and application thereof and vacuum consumable electro-arc furnace

A vacuum arc melting and alloy target technology, which is applied in vacuum evaporation plating, metal material coating technology, lighting and heating equipment, etc., can solve the problems of coarse grain structure of the target material and uniform melt mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing an aluminum-scandium alloy target, comprising the following steps:

[0036] The aluminum source and the scandium source are mixed and pressed to obtain a consumable electrode;

[0037] Welding the consumable electrodes to obtain welding electrodes;

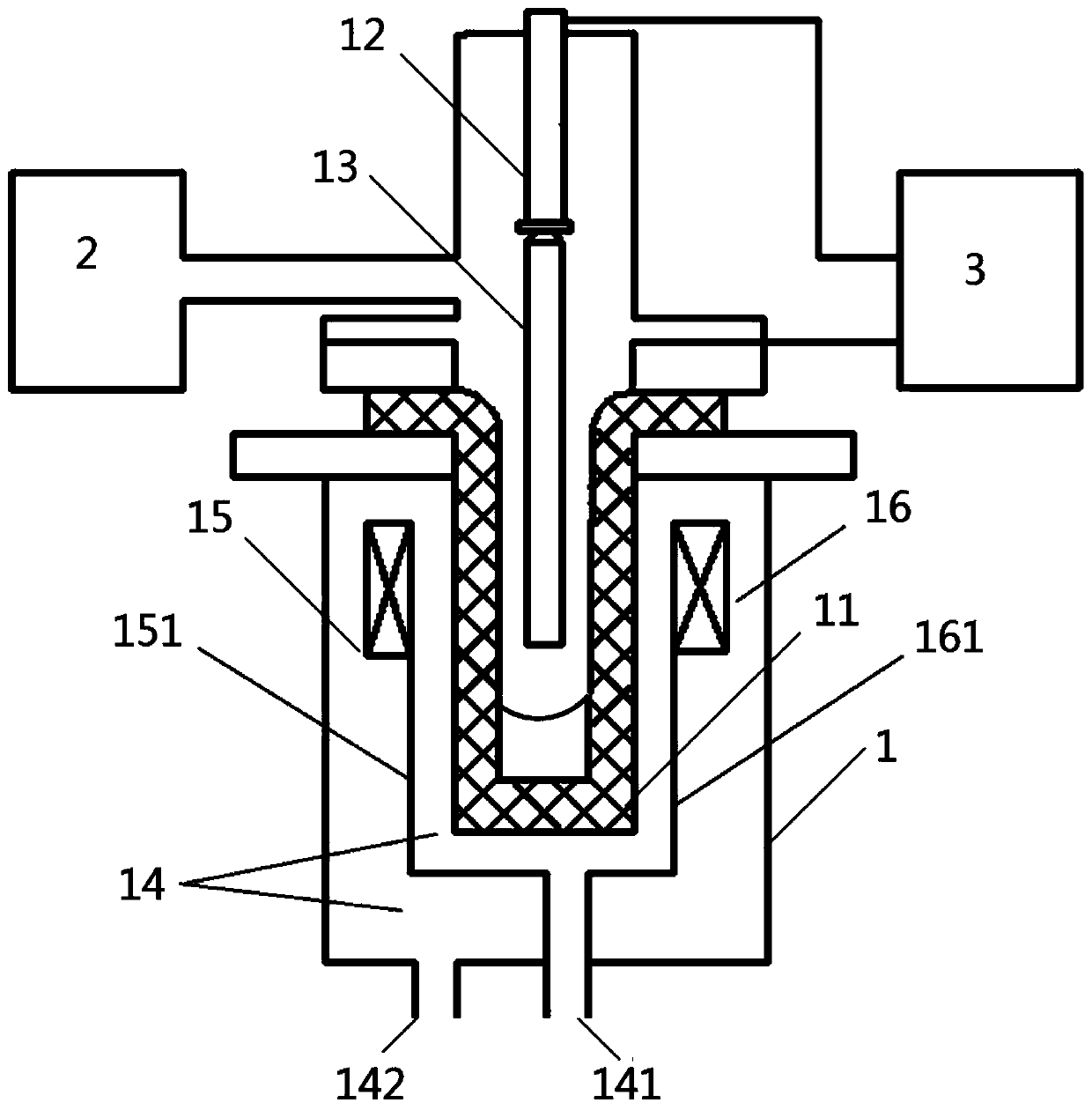

[0038] placing the assembly welding electrodes in a water-cooled copper crystallizer to carry out the first vacuum arc melting and the first condensation in sequence to obtain primary ingots of aluminum scandium;

[0039] placing the aluminum-scandium primary ingot in a water-cooled copper crystallizer to perform the second vacuum arc melting and the second condensation in order to obtain the aluminum-scandium secondary ingot;

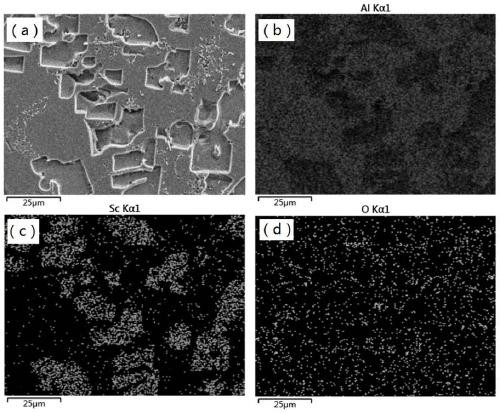

[0040] Repeating thermomechanical processing of the aluminum-scandium secondary ingot to obtain an aluminum-scandium alloy target;

[0041] The arc starting material is installed in the water-cooled copper crystallizer.

[0042] In the present inventi...

Embodiment 1

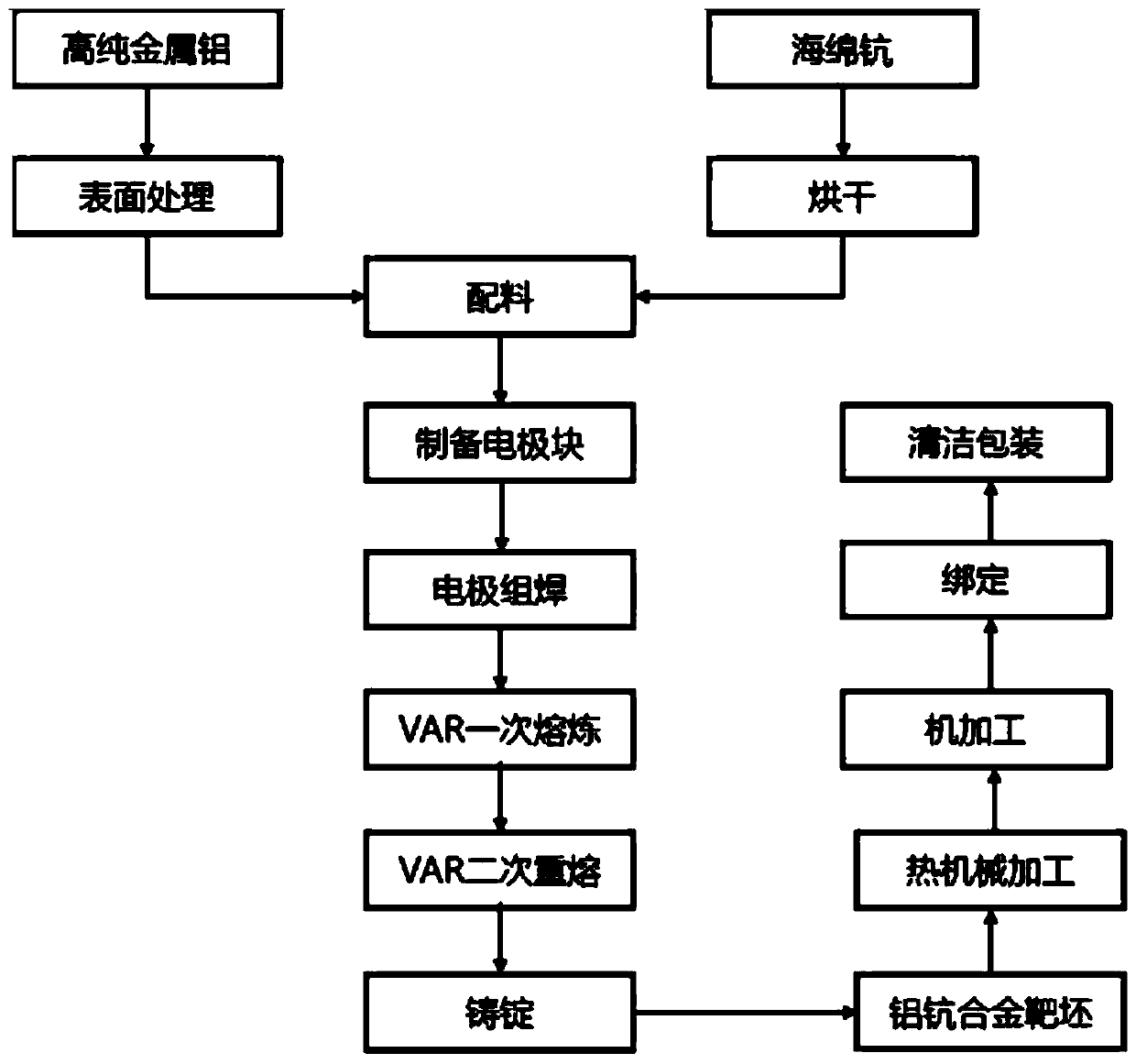

[0087] Use the process flow shown in Figure 1 to prepare an aluminum-scandium alloy sputtering target, and the specific steps are as follows:

[0088] (1) Aluminum (purity is 99.999%) is mechanically descaled, and a sulfuric acid solution with a concentration of 95wt% is used for degreasing treatment, washed with water to remove residual sulfuric acid solution and metal ions, and then placed in a vacuum drying oven at 25°C Drying; sponge scandium (purity is 99.99%) is dried in a vacuum drying oven at 25°C; the treated sponge scandium and aluminum are mixed evenly according to the ratio of 3at%:97at%, and the obtained aluminum scandium alloy ingredients are mixed in the Pressing at 400MPa for 5min, the density is 4g / cm 3 self-consumable electrodes.

[0089] (2) Four consumable electrodes with a mass of 70 g were assembled and welded by vacuum electron beam to obtain assembled welding electrodes, wherein the focusing current of vacuum electron beam was 1.5A, and the assembled w...

Embodiment 2

[0094] The aluminum-scandium alloy target was prepared according to the method of Example 1, the difference from Example 1 is:

[0095] In step (1), spongy scandium: aluminum=5at%: 95at%;

[0096] In step (2), the mass of a single consumable electrode is 75g;

[0097] In step (3), the electric current of the first vacuum arc melting is 2400A;

[0098] In step (4), the electric current of the second vacuum arc melting is 8000A;

[0099] In step (5), the temperature of the longitudinal rolling is 430° C., the time is 4 minutes, and the deformation of a single longitudinal rolling is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com