Aluminum-scandium alloy target blank and preparation method and application thereof

An alloy target, an aluminum-scandium technology, which is applied in the field of aluminum-scandium alloy target blank and its preparation, can solve the problems of affecting film-forming performance, uneven microstructure, and scandium segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

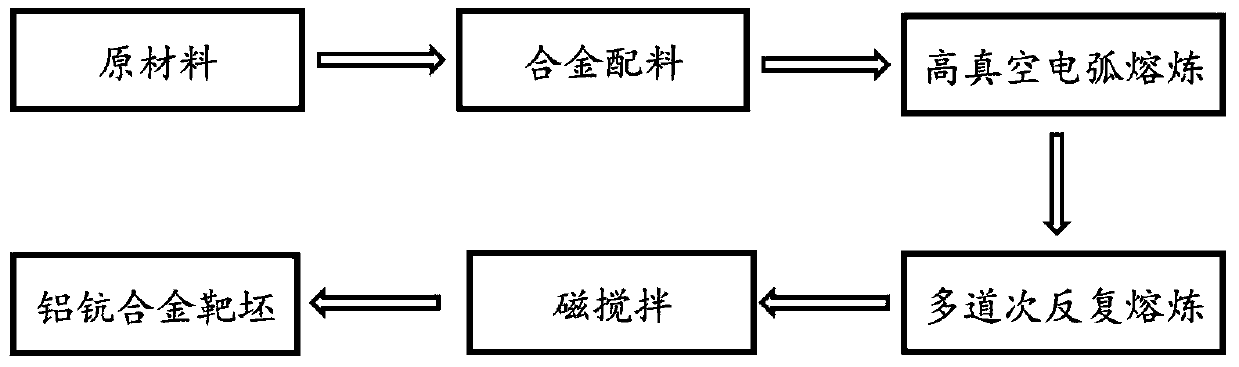

[0026] The invention provides a method for preparing an aluminum-scandium alloy target blank, comprising the following steps:

[0027] Put the aluminum source and the scandium source in a water-cooled copper crucible, vacuumize it and fill it with an inert gas, and repeat the arc melting to obtain a molten alloy;

[0028] Condensing the molten alloy liquid under the protection of an inert gas to obtain an aluminum-scandium alloy ingot;

[0029] The aluminum-scandium alloy ingot is subjected to electromagnetic stirring and repeated thermomechanical treatment in sequence to obtain an aluminum-scandium alloy target blank.

[0030] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0031] The aluminum source and the scandium source are placed in a water-cooled copper crucible, vacuumized and then filled with an inert gas, and arc melting is repeated to obtain molten alloy ...

Embodiment 1

[0054] as per image 3 The process shown in the preparation of aluminum scandium alloy target blank, the specific steps are as follows:

[0055] (1) Dip aluminum (purity: 99.999%) into ethyl acetate for wiping with absorbent cotton, then wash with concentrated sulfuric acid (95% by mass), wash with water to remove residual sulfuric acid solution and metal ions, and then place in vacuum Dry in a drying oven at 25°C; scandium (purity: 99.99%) is dried in a vacuum oven at 25°C; aluminum: scandium = 65at%: 35at%, the total mass is 150g.

[0056] (2) Place the treated aluminum on the bottom of the water-cooled copper crucible in the high vacuum arc melting furnace, place the treated scandium on the aluminum surface, and use vacuum grease to seal the furnace body of the high vacuum arc melting furnace. The pump is evacuated 4 times, and then the molecular pump is used to evacuate to a pressure of 3.4×10 -3 Pa, then filled with high-purity argon gas to a pressure of -0.05MPa, adjus...

Embodiment 2

[0059] According to the method of embodiment 1, the aluminum-scandium alloy target blank is prepared, and the difference from embodiment 1 is:

[0060] In step (1), acetone replaces ethyl acetate, scandium: aluminum=40at%: 60at%;

[0061] In step (2), the maximum current of arc melting is 430A, the time of single arc melting is independently 70s, and the condensation time is 45s;

[0062] In step (3), the electric current of the electromagnetic stirring is 335A, and the deformation rate of a single ingot rolling is 27%; Density>97%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com