Method for forging mold cavity (female mold) module

A cavity and concave core technology, which is applied in the field of metal forging, can solve the problems of long time consumption, waste of metal materials, and many processing steps, and achieve the effect of reducing processing steps, avoiding waste and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The size and shape are (900+20 / -0×1000+20 / -0) mm cavity (concave) module.

[0035] 1. Smelting: UHP+LF+VD steelmaking is adopted, one 30t ingot is poured, the VD tapping temperature is 1565°C, furnace number: 13203013752;

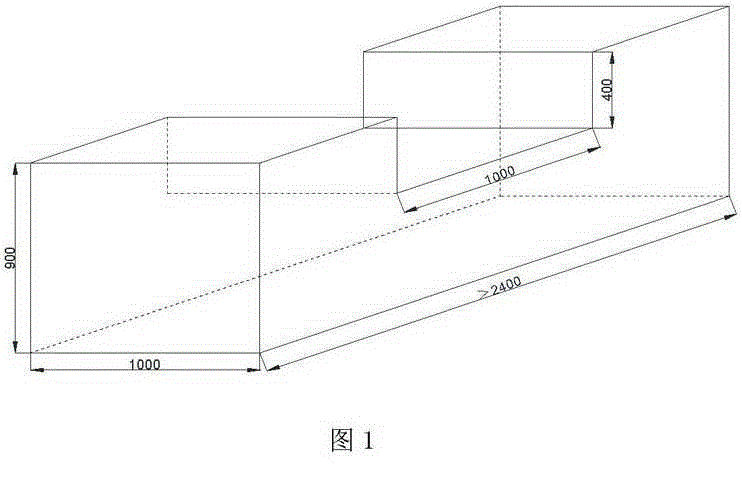

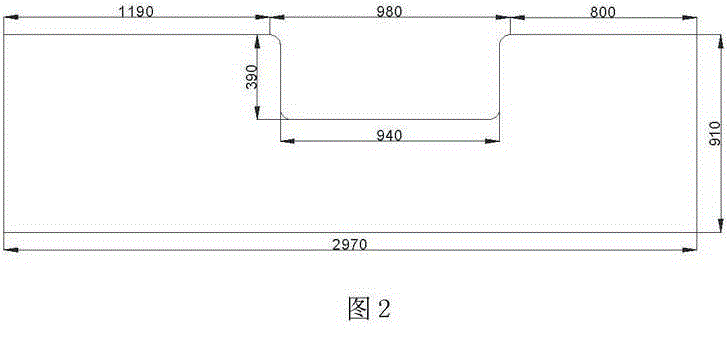

[0036] 2. Forging: ①When forging, heat the steel ingot to 1230°C in the first fire, press the clamp after holding it for 18 hours; The height of the ingot is 1150mm, the upsetting ratio is ≥ 2, and it is drawn once to grow into a flat square of 1300mm×1200mm with a length of 2550mm; ③The steel ingot is returned to the furnace and heated to 1230°C with three fires, and then secondly upset after 5 hours of heat preservation. The height of the ingot before upsetting is 2550mm, and the height of the ingot after upsetting 1270mm, upsetting ratio ≥ 2; figure 1 , figure 2 As shown, there are two heavy pressings in the second drawing, the reduction in the first pass is 190mm, and the reduction in the second pass is 180mm to ensure the deformation of the c...

Embodiment 2

[0048] The size and shape are (850+20 / -0×970+20 / -0) mm cavity (concave) module.

[0049] 1. Smelting: UHP+LF+VD steelmaking is adopted, one 27t ingot is poured, the VD tapping temperature is 1565°C, furnace number: 13203013752;

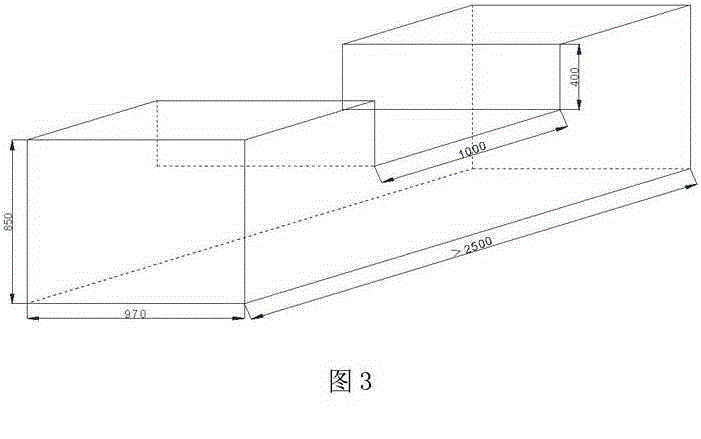

[0050] 2. Forging: ①When forging, heat the steel ingot to 1230°C in the first fire, press the pliers after holding it for 18 hours; The height of the ingot is 1150mm, the upsetting ratio is ≥ 2, and it is drawn once to grow into a 1200mm×1100mm flat square with a length of 2580mm; ③The steel ingot is returned to the furnace and heated to 1230°C with three fires, and then secondly upset after 5 hours of heat preservation. The height of the ingot before upsetting is 2580mm, and the height of the ingot after upsetting 1270mm, upsetting ratio ≥ 2; image 3 , Figure 4 As shown, there are two heavy pressings in the second drawing, the reduction of the first pass is 180mm, and the reduction of the second pass is 180mm to ensure the deformation of the core. ...

Embodiment 3

[0062] The size and shape are 982+20 / -0mm×1015+20 / -0mm cavity (concave center) module.

[0063] 1. Smelting: UHP+LF+VD steelmaking is adopted, one 33t ingot is poured, the VD tapping temperature is 1560℃, furnace number: 13203023903;

[0064] 2. Forging: ①When forging, heat the steel ingot to 1230°C in the first fire, press the pliers after holding it for 20 hours; The steel ingot height is 1160mm, the upsetting ratio is ≥ 2, and the length of the steel ingot is 1300mm×1200mm flat and 2560mm in one drawing; ③The steel ingot is returned to the furnace and heated to 1230°C with three fires, and the second time is upsetting after 5 hours of heat preservation. 1250mm, upsetting ratio ≥ 2; Figure 5 , Figure 6 As shown, there are two heavy pressings in the second drawing, the reduction in the first pass is 200mm, and the reduction in the second pass is 195mm to ensure the deformation of the core. It is forged into a 1060mm×1090mm module with a wide anvil, and the width and thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com