Rolling technology for controlling decarbonization of 42CrMo steel bloom hot-rolled wire rod

A hot-rolled wire rod and bloom technology, which is applied in the field of metallurgy, can solve the problems of unpublished research reports on decarburization control technology, and achieve the effects of avoiding severe decarburization, solving decarburization exceeding the standard, and reducing decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Using 325mm×280mm bloom heating-opening-pit cooling-heating-wire rolling-roller cooling process to produce Φ13mm wire rod for high-strength bolts, the chemical composition of the 42CrMo steel used is: C: 0.38~0.45 %, Si: 0.17~0.37%, Mn: 0.50~0.80%, S: ≤0.030%, P≤0.030%, Cr: 0.90~1.20%, Ni: ≤0.25%, Cu: ≤0.030, Mo: 0.15~0.25 %, the balance being Fe, a rolling process for controlling the decarburization of 42CrMo steel bloom hot-rolled wire rods, carried out according to the following steps:

[0033] (1) The 42CrMo steel 280mm × 325mm bloom of the above-mentioned composition is blanked. During the blanking process, the parameters of the blanking heating furnace are: heating temperature 1200°C, heating time 8h, and residual oxygen controlled at 2.5%;

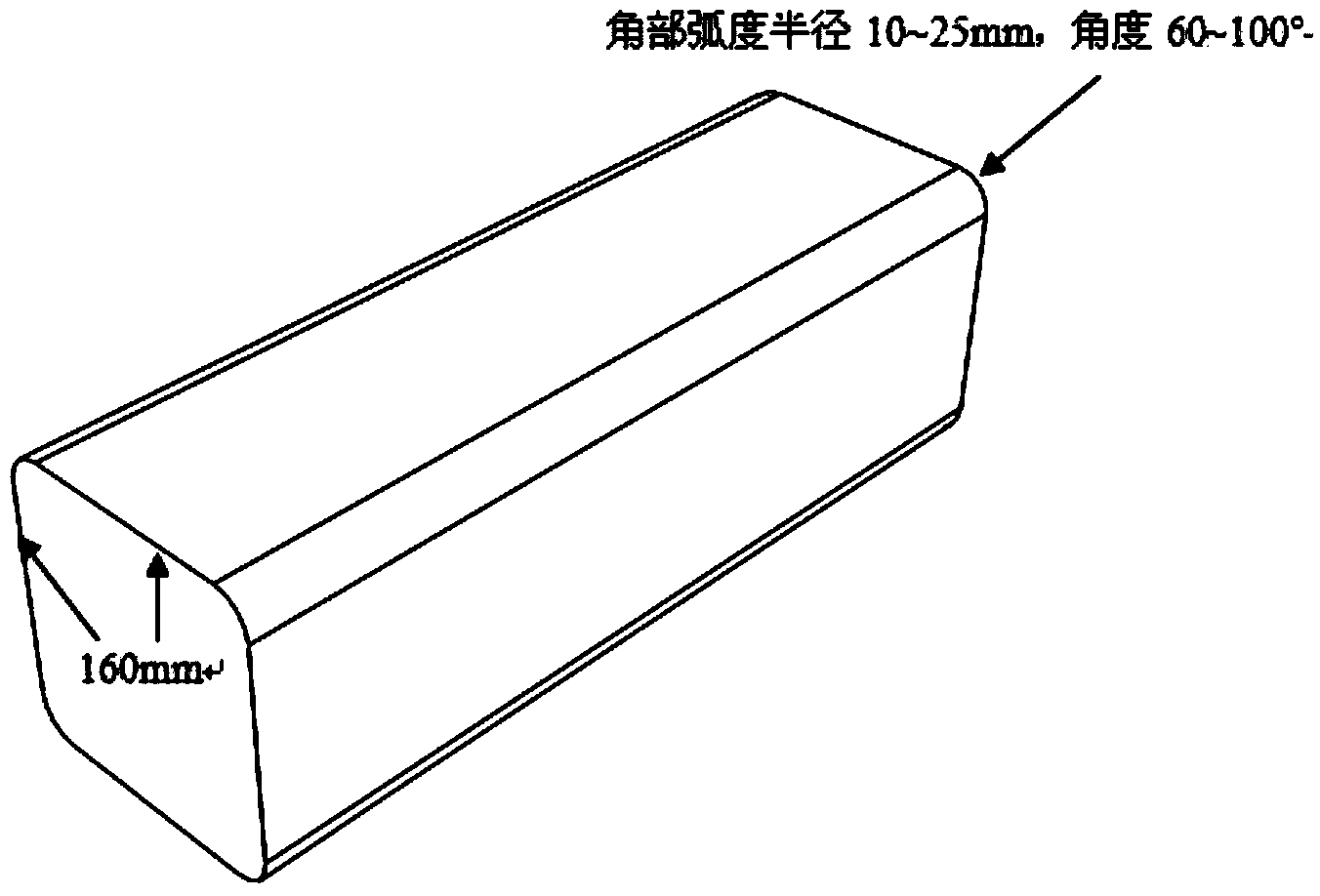

[0034] (2) Grind the 160mm×160mm steel billet after billet opening, grind 4mm, cut off the head and tail 200mm, and grind the corners 5mm, and there should be no right angles at the corners. For this reason, the radius of the c...

Embodiment 2

[0042] Using 325mm×280mm bloom heating-opening-pit cooling-heating-wire rolling-roller cooling process to produce Φ10mm wire rod for high-strength bolts, the chemical composition of the 42CrMo steel used is: C: 0.38~0.45 %, Si: 0.17~0.37%, Mn: 0.50~0.80%, S: ≤0.030%, P≤0.030%, Cr: 0.90~1.20%, Ni: ≤0.25%, Cu: ≤0.030, Mo: 0.15~0.25 %, the balance being Fe, a rolling process for controlling the decarburization of 42CrMo steel bloom hot-rolled wire rods, carried out according to the following steps:

[0043] (1) The 42CrMo steel 280mm × 325mm bloom of the above-mentioned composition is blanked, and the parameters of the blanking heating furnace during the blanking process are: heating temperature 1180°C, heating time 8h, residual oxygen controlled at 3.5%;

[0044] (2) Grind the 160mm×160mm steel billet after billeting, grind 3mm, cut off the head and tail by 150mm, and grind the corner by 5mm, and there should be no right angle at the corner. For this reason, the radius of the co...

Embodiment 3

[0050] Using 325mm×280mm bloom heating-opening-pit cooling-heating-wire rolling-roller cooling process to produce Φ10mm wire rod for high-strength bolts, the chemical composition of the 42CrMo steel used is: C: 0.38~0.45 %, Si: 0.17~0.37%, Mn: 0.50~0.80%, S: ≤0.030%, P≤0.030%, Cr: 0.90~1.20%, Ni: ≤0.25%, Cu: ≤0.030, Mo: 0.15~0.25 %, the balance being Fe, a rolling process for controlling the decarburization of 42CrMo steel bloom hot-rolled wire rods, carried out according to the following steps:

[0051] (1) The 42CrMo steel 280mm × 325mm bloom of the above composition is blanked, and the parameters of the blanking heating furnace during the blanking process are: heating temperature 1150°C, heating time 9h, and residual oxygen content controlled at 4.5%;

[0052] (2) Grind the 160mm×160mm steel billet after billet opening, grind 2mm, cut off the head and tail 100mm, and grind the corners by 3mm, and there should be no right angles at the corners. For this reason, the radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com