Intermediate-strength aluminum alloy wire and process for manufacturing same

A medium-strength aluminum alloy, production process technology, applied in the direction of metal/alloy conductor, rod/rod/wire/strip conductor, cable/conductor manufacturing, etc., can solve the problem of poor overload resistance and fatigue resistance of wires, medium strength The problems of low elongation of aluminum alloy wires and large energy consumption during aging process can achieve the effects of good electrical conductivity, improved electrical conductivity, and labor and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

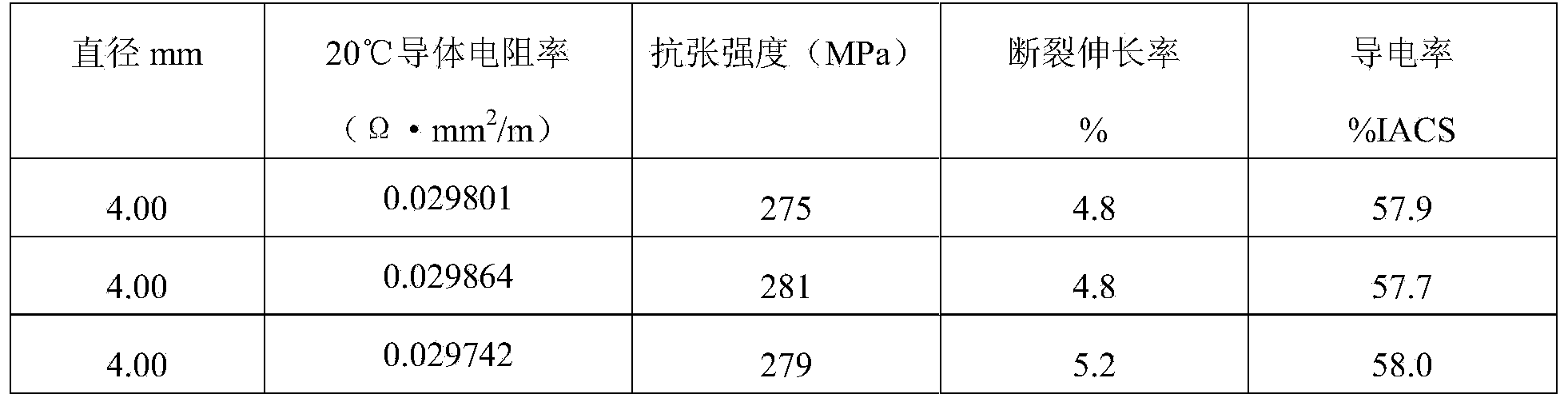

Image

Examples

Embodiment Construction

[0012] The process steps are:

[0013] 1. Select an aluminum ingot and melt it. The selected aluminum ingot composition Al: 99.79wt%, the impurities in the aluminum ingot should meet Si: 0.06wt%, (Cr+V+Mn+Ti)≤0.013wt%, Fe: 0.13wt%, Cu: 0.002wt%, each The sum of similar impurities is 0.21wt%;

[0014] 2. Alloy configuration and stirring. Add aluminum-silicon alloy ingots (AlSi12), aluminum-iron alloy ingots (AlFe20), aluminum-boron alloy ingots (AlB3), rare earth aluminum alloy ingots (AlRe10), and magnesium ingots respectively, using a combination of electromagnetic stirring and manual stirring, stirring evenly, and sampling Spectral analysis, the mass percentage of each element in the furnace is as follows: Si: 0.56wt%, the content of Mg is 0.63wt%, (Cr+V+Mn+Ti): 0.011wt%, the content of B is 0.021wt%, the content of Fe 0.22wt%, Cu content is 0.02wt%, rare earth content is 0.11wt%;

[0015] 3. Refining and degassing in the furnace, removing slag and standing still. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com