Aluminum alloy lead with lanthanon yttric and preparation method thereof

A technology of rare earth elements and aluminum alloys, which is applied in the manufacture of cables/conductors, metal/alloy conductors, circuits, etc., can solve the problems of unsatisfactory complex natural conditions, rain, snow, freezing and long-distance cross-sea wiring, etc., so as to improve the strength and Thermal stability, reduced pinhole rate, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

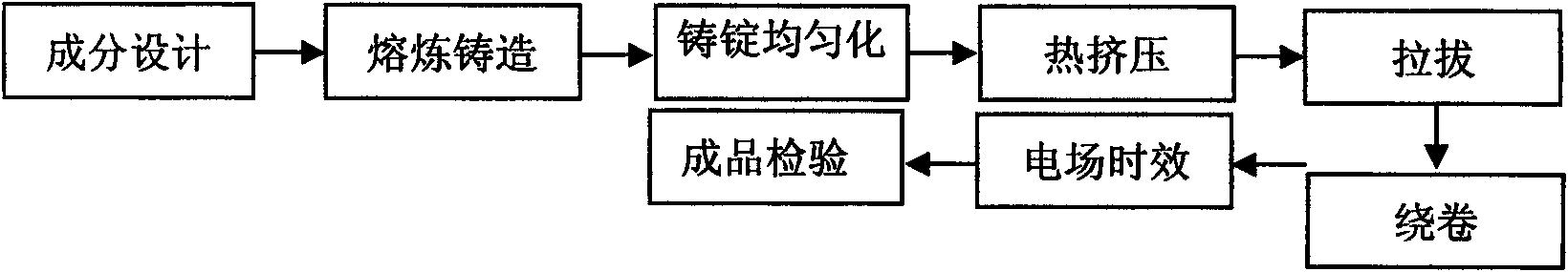

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: get No. 2 technical pure aluminum 100 kilograms, it contains aluminum 99.7%, iron 0.10%, silicon 0.04%, gallium 0.01%; No. 2 commercial pure magnesium 1 kilogram; Aluminum-silicon intermediate alloy (10% Si) 5 kg; 1.5 kg of aluminum-yttrium master alloy (14% Y); put the rising raw material into a box-type resistance furnace for smelting in batches, first put the prepared aluminum material into the crucible, heat and melt it with a resistance furnace, and wait for the pure aluminum After complete melting, add dry KCl+NaCl (mass percentage 1:1) solvent to cover (both prevent oxidation and adsorption slagging and refining). When the temperature of the molten aluminum reaches 700°C, the aluminum-silicon master alloy is added, and after the aluminum-silicon master alloy is melted, pure magnesium is added and pressed into the bottom of the molten pool. Then add the Al-Y master alloy at 700 ° C, and use hexachloroethane (C 2 Cl 6 ) Degassing agent degassing, st...

Embodiment 2

[0023] Embodiment 2: 100 kilograms of No. 2 industrial pure aluminum, 1 kilogram of No. 2 industrial pure magnesium; 4.17 kilograms of aluminum-silicon master alloy (12% Si); 2.1 kilograms of aluminum-yttrium master alloy (12% Y); Put the aluminum material into the crucible, heat and melt it with a resistance furnace, add the dried MgCl+NaCl+KCl (1:1:1) solvent to cover after the pure aluminum is completely melted, and then add pure magnesium, silicon-aluminum alloy and silicon-yttrium alloys. The melted aluminum alloy melt is cast at 700-710° C. into an aluminum ingot with a diameter of 50 mm. The 50mm ingot is homogenized at 450°C / 10 hours in a resistance furnace, and then directly extruded into a 14mm screw, which is drawn into a 3-8mm cable wire on a 100-ton cold drawing machine, and then in the frame Coil on the winding machine. The coiled cables are subjected to aging treatment at 250°C / 4 hours in an electric field aging furnace with an electric field strength of 12kV / ...

Embodiment 3

[0024] Embodiment 3: 100 kilograms of No. 2 industrial pure aluminum, 1 kilogram of No. 2 industrial pure magnesium; 3.57 kilograms of aluminum-silicon master alloy (14% Si); 2.8 kilograms of aluminum-yttrium master alloy (10% Y); Put the aluminum material into the crucible, heat and melt it with a resistance furnace, and then add the dried KCl+MgCl after the pure aluminum is completely melted 2 +BaCl 2 +CaF 2 (40:40:5:15) solvent covering, then add pure magnesium, silicon-aluminum alloy and silicon-yttrium alloy. . The melted aluminum alloy melt is cast at 700-710° C. into an aluminum ingot with a diameter of 50 mm. The 50mm ingot is homogenized at 450°C / 10 hours in a resistance furnace, and then directly extruded into a 14mm screw, which is drawn into a 3-8mm cable wire on a 100-ton cold drawing machine, and then in the frame Coil on the winding machine. The coiled cables are subjected to aging treatment at 150°C / 10 hours in an electric field aging furnace with an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com