Steel cord and single steel wire having excellent straightness quality for reinforcing tire and manufacturing method thereof

A technology for steel cords and manufacturing methods, applied in textiles and papermaking, manufacturing tools, tire parts, etc., can solve problems such as steel cords and single steel wires that are difficult to meet linearity quality and cannot provide excellent linearity, Achieving excellent straight line quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

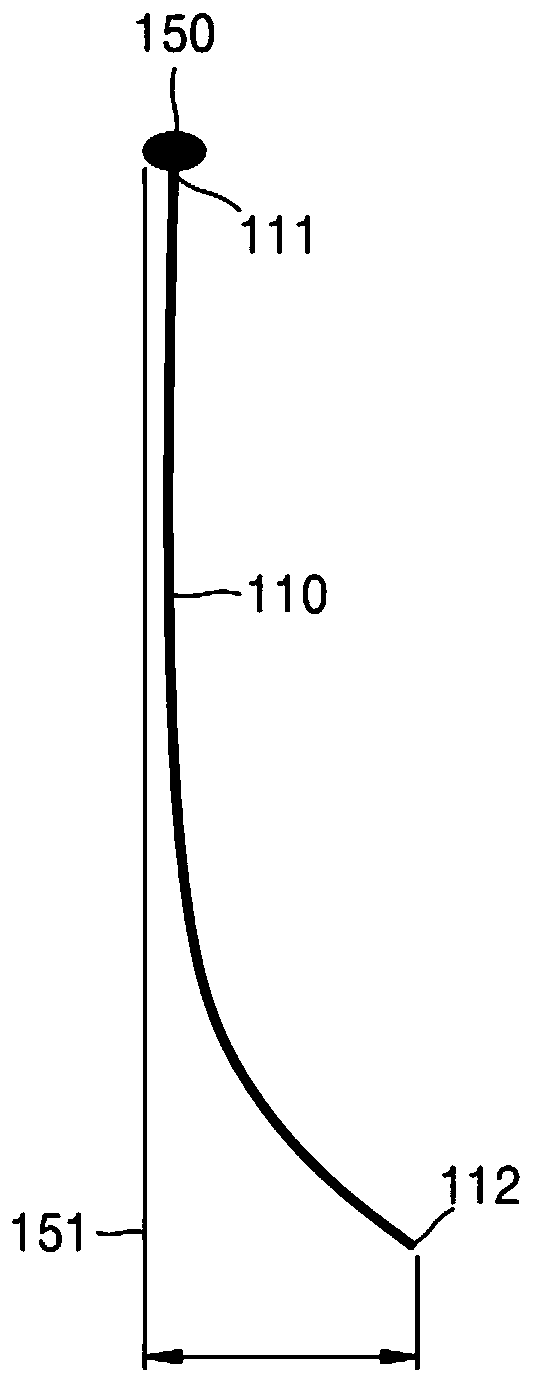

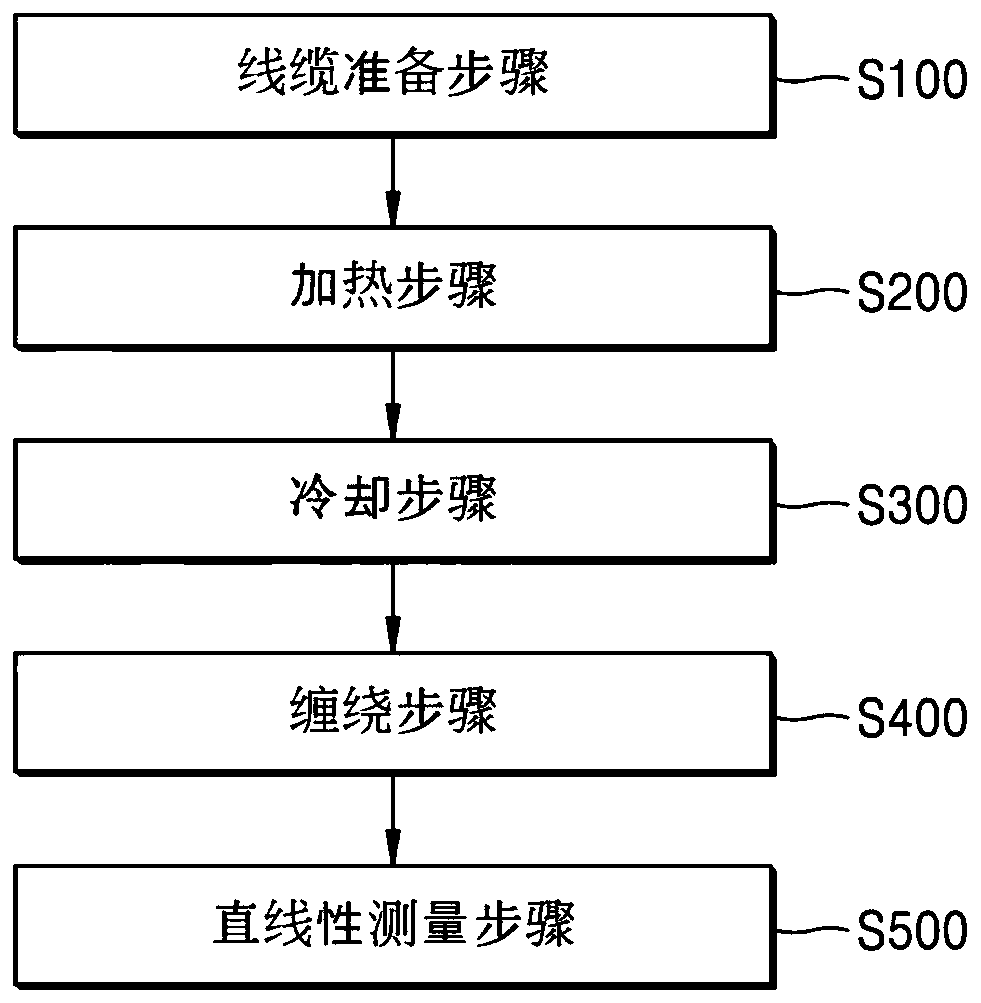

[0022] The present invention relates to a steel cord for tire reinforcement having excellent linear quality and a single steel wire and a manufacturing method thereof, and more particularly to a steel cord for tire reinforcement and a single steel wire having excellent linear quality and a manufacturing method thereof, which is achieved by making the steel wire The cord and the single steel wire are heated and cooled to remove the stress remaining on the steel cord and the single steel wire, so as to promote the strain aging of the steel cord and the single steel wire to improve the straight line quality after aging. Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0023] The steel cord for tire reinforcement having excellent linear quality and the single steel wire of the present invention may include a cable 110 and a winding unit 120 capable of being wound by the cable 110 .

[0024] After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com