Antiskid connecting pad and fabrication technology thereof

A manufacturing process and technology of connection pads, applied in the field of non-slip connection pads and its manufacturing process, to achieve the effects of low density, cleanliness, and easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

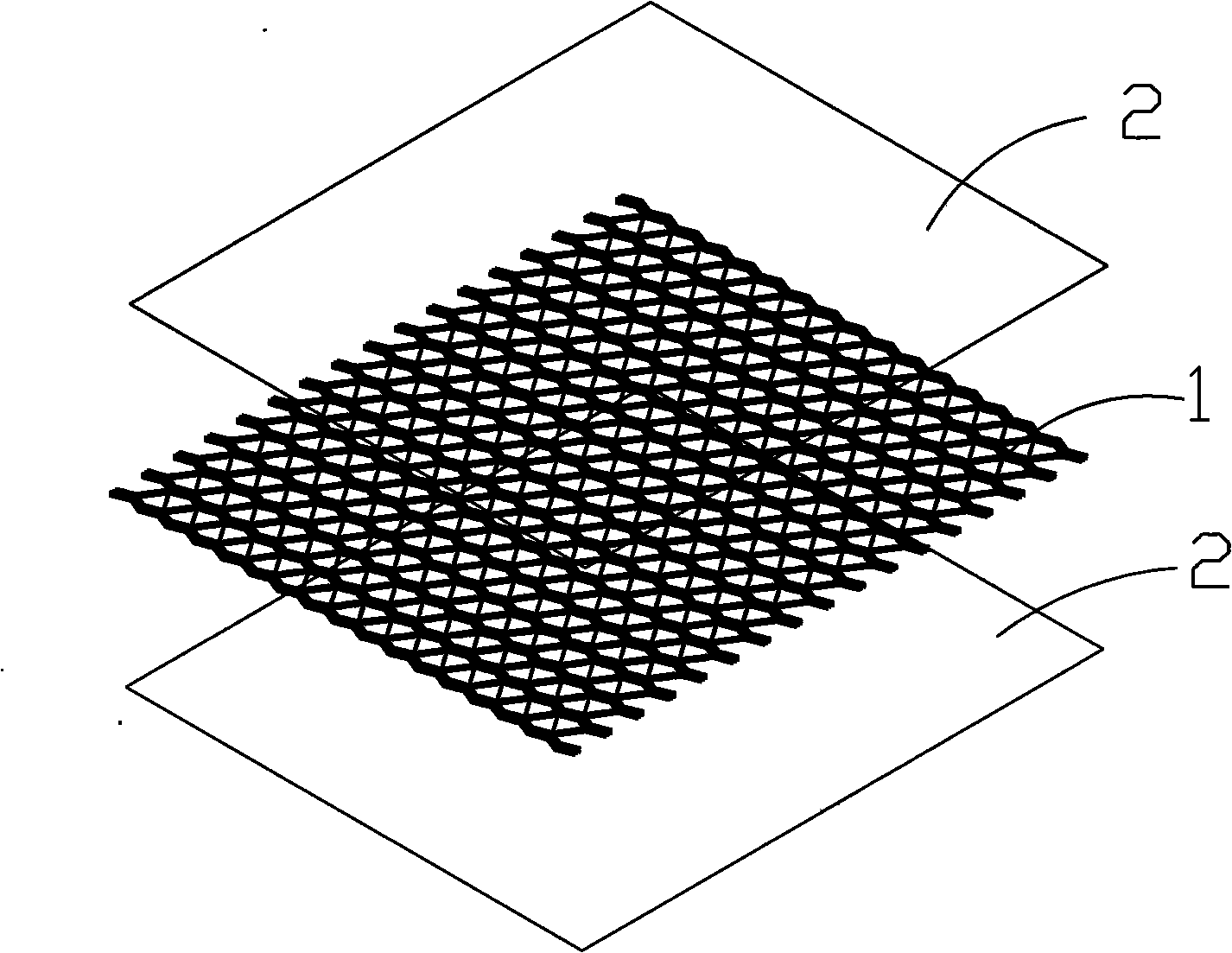

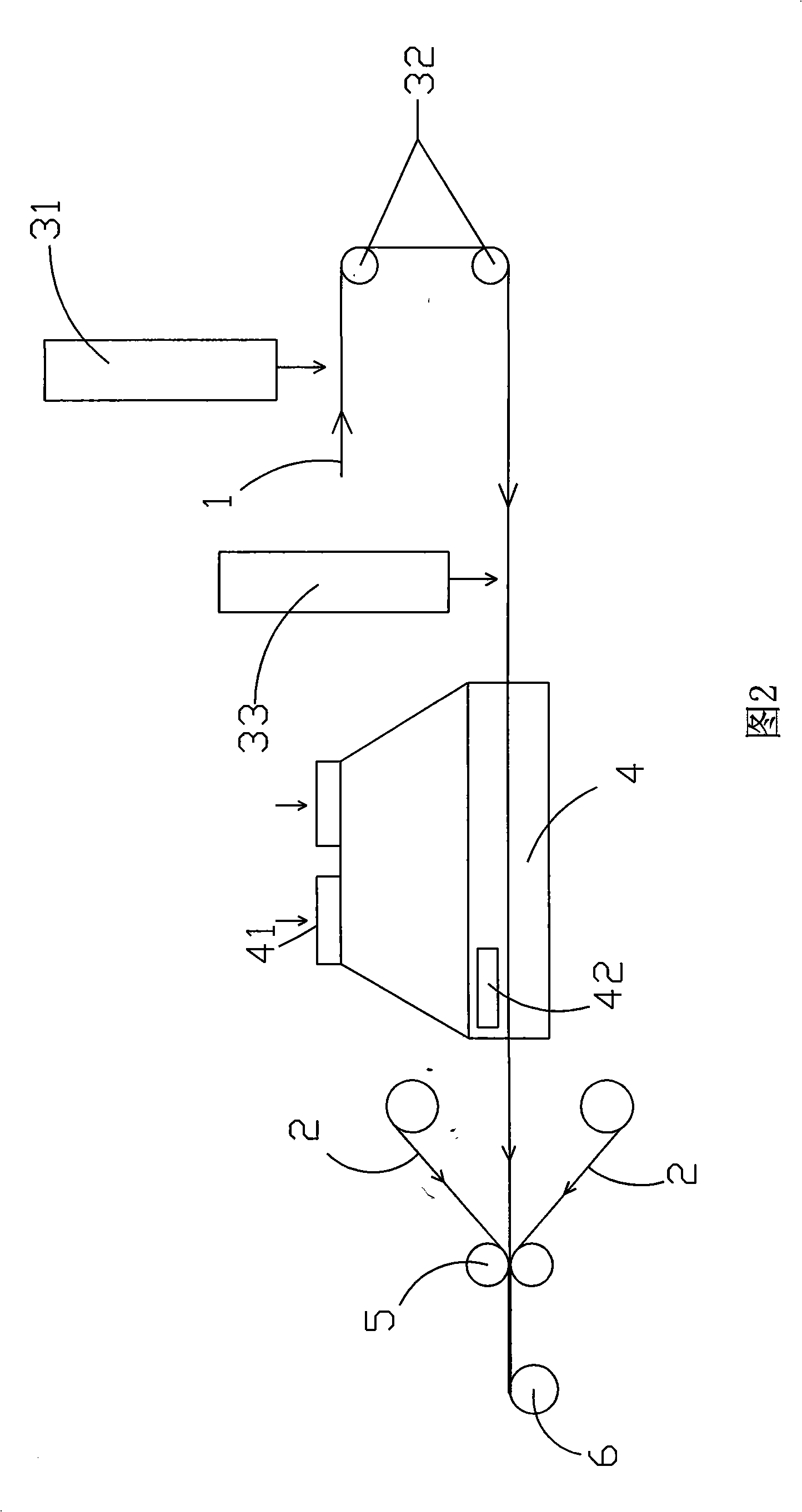

[0022] like figure 1 As shown, the non-slip connection pad of the present invention includes three layers, wherein the knitted mesh cloth 1 is located in the middle, and the protective film 2 is located on both sides of the mesh cloth 1, wherein the knitted mesh cloth is made of PET material or nylon Or made of polyester, the specification is about 120g / m 2 , the thickness is 1.016mm, and the two sides of the knitted mesh cloth 1 are coated with self-adhesive; the protective film 2 on the two sides is made of PE or PVC material, pasted by the self-adhesive of the knitted mesh cloth 1 On both sides of the knitted grid cloth 1 , the thicknesses of the two protective films 2 may be different, or they may be the same, or they may be differentiated by color. In this embodiment, one of the protective films is yellow, made of PE material, and the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com