Melamine salt flame retardant, flame-retardant polyamide film and preparation method thereof

A technology of flame retardant polyamide and melamine salt, which is applied in the field of melamine salt flame retardant, flame retardant polyamide film and preparation thereof, and can solve the problems of flame retardancy and mechanical properties of flame retardant polyamide film. Comprehensive problems such as poor performance, to achieve the effect of improving compatibility, reducing crystallization ability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of melamine ammonium salt flame retardant provided by the invention comprises the steps:

[0065] (1) Add the dibasic acid compound and thionyl chloride into the reaction vessel, react at 70-78° C. for 3 to 5 hours to generate acid chloride, and remove the remaining thionyl chloride by distillation under reduced pressure; the dibasic acid compound The molar ratio with thionyl chloride is 0.8~1.0:1;

[0066](2) Esterify the acid chloride obtained in step (1) with tetrahydrofurfuryl alcohol, react at 85-100°C for 1-2 hours, heat up until the solution has reflux, and then react for 3-4 hours. After the reaction is completed, distill under reduced pressure Remove the raw material, pour the mixture into ice water, adjust the pH to 5-7, and obtain the intermediate; taking the molar number of the dibasic acid compound described in step (1) as the basis, the amount of tetrahydrofurfuryl alcohol and the dibasic acid compound The molar ratio is 1~1.2:1;

...

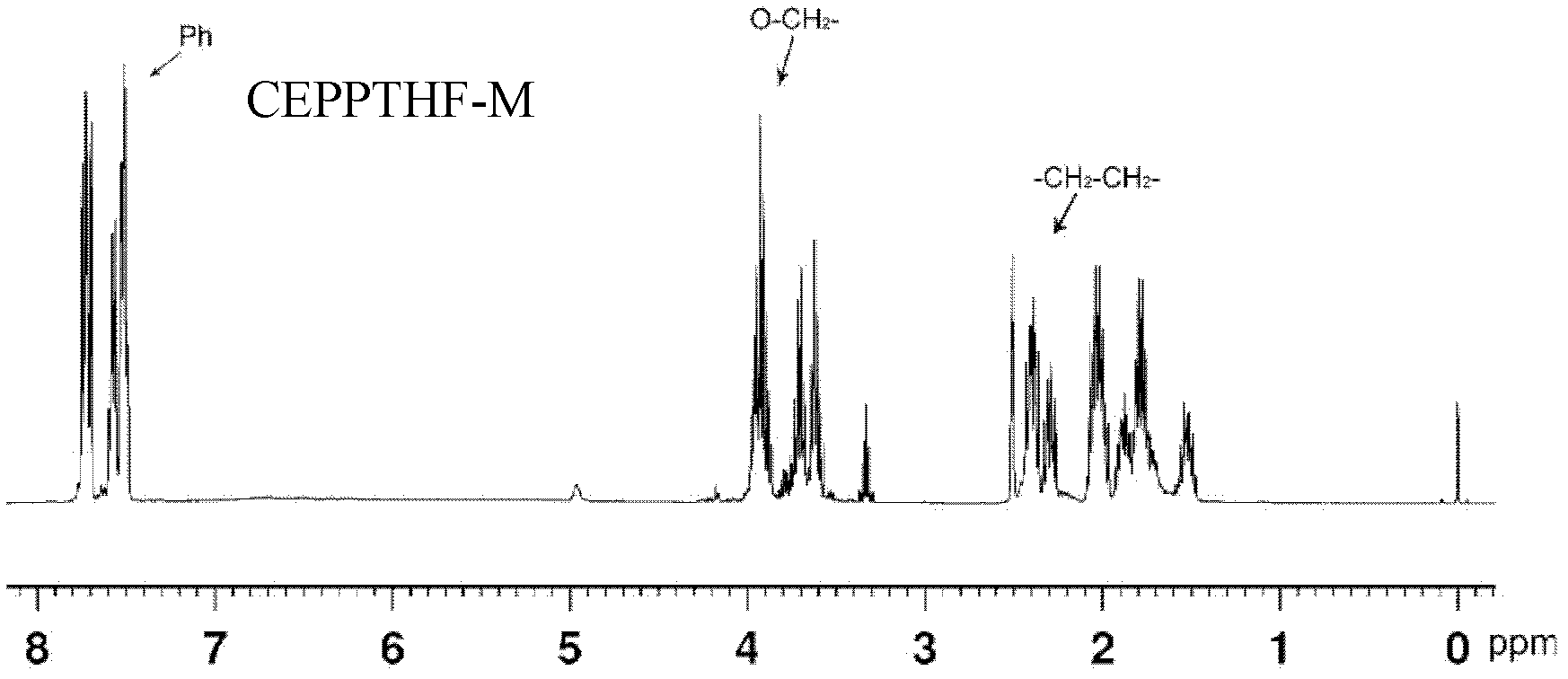

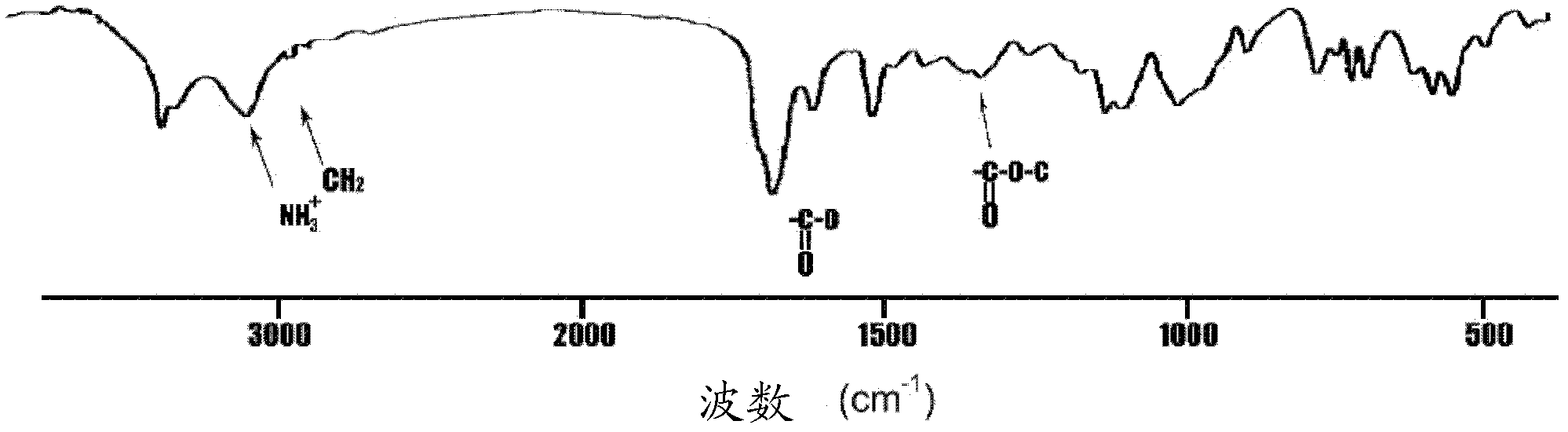

Embodiment 1

[0077] The following figure is the synthesis diagram of the flame retardant 3-(hydroxy-phenyl-phosphoryl)-tetrahydrofurfuryl propionate melamine salt (CEPPTHF-M):

[0078]

[0079] In a four-neck flask equipped with a stirring device, a thermometer, and a dropping funnel, add 1 mole of 3-(hydroxyl-phenyl-phosphoryl)-propionic acid (CEPP) and 1 mole of thionyl chloride respectively, and heat to make CEPP was dissolved, then two drops of dried pyridine were added dropwise, and the temperature was kept at 78°C for 3 hours. After the reaction, distill under reduced pressure and add an appropriate amount of toluene and repeat under reduced pressure to remove thionyl chloride. Add toluene to make it dissolve, then dropwise add 1 mole of tetrahydrofurfuryl alcohol, keep a certain temperature at 96°C, and react for 1.5h, after the addition, raise the temperature until there is reflux, and then react for 3h. After completion of the reaction, the raw material was distilled off under...

Embodiment 2

[0083] The following figure is the synthesis diagram of the flame retardant 3-(hydroxy-naphthyl-phosphoryl)-tetrahydrofurfuryl propionate melamine ammonium salt (CENPTHF-M):

[0084]

[0085] In a four-neck flask equipped with a stirring device, a thermometer, and a dropping funnel, add 0.8 moles of 3-(hydroxy-naphthyl-phosphoryl)-propionic acid (CENP) and 1 mole of thionyl chloride respectively, and heat to make CEPP was dissolved, then two drops of dried pyridine were added dropwise, and the temperature was kept at 70°C for 5 hours. After the reaction, distill under reduced pressure and add an appropriate amount of toluene and repeat under reduced pressure to remove thionyl chloride. Add xylene (DMB) to dissolve it, then dropwise add 0.9 mole of tetrahydrofurfuryl alcohol, keep a certain temperature of 100°C, and react for 1 hour. After completion of the reaction, the raw material was distilled off under reduced pressure. After cooling, the mixture was poured into ice w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com