Packaging method for electroluminescence devices

A technology of electroluminescent devices and packaging methods, which is applied to electrical components, semiconductor devices, circuits, etc., and can solve the problems of reduced sealing performance, easy cracking and brittle epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

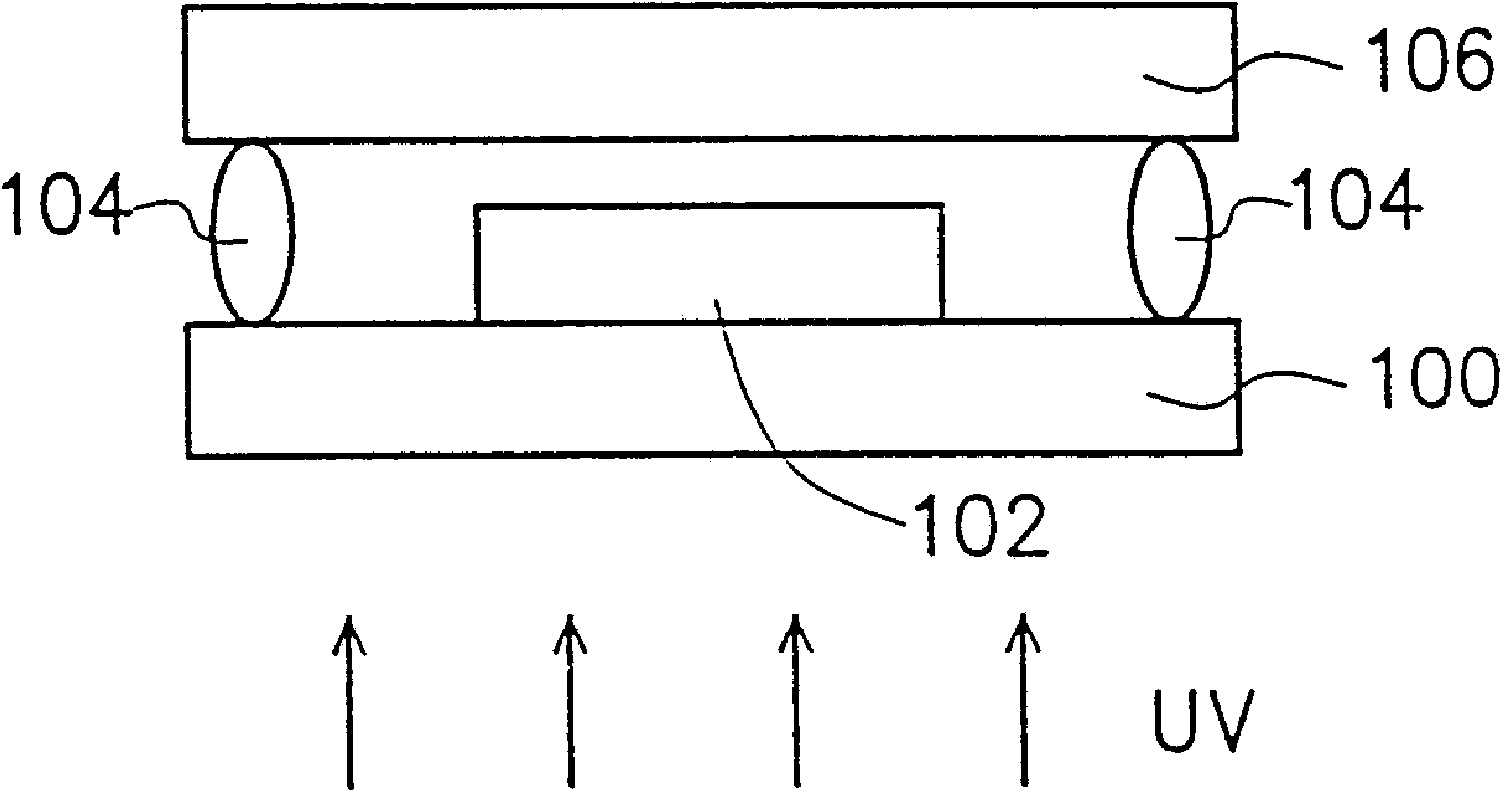

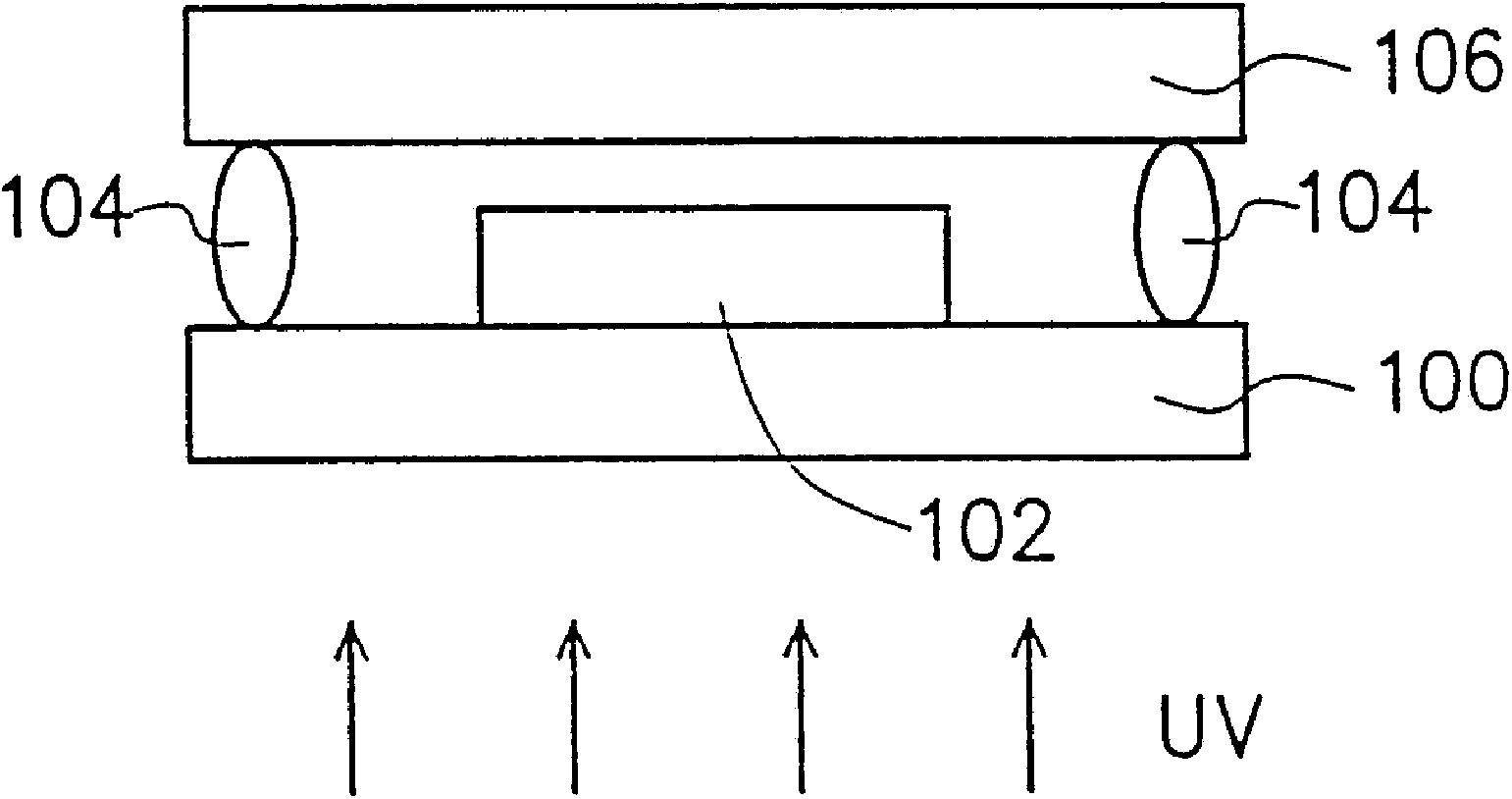

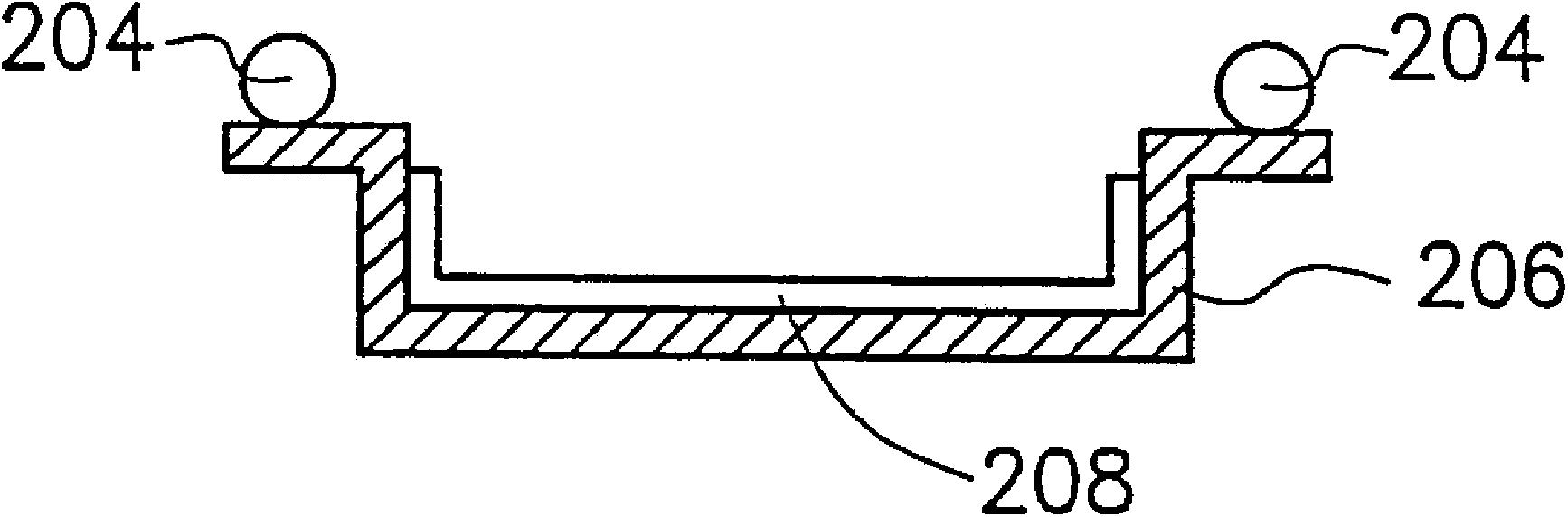

Image

Examples

Embodiment Construction

[0027] Its technical route is as follows:

[0028] Preparation of silicone-modified epoxy resin matrix material:

[0029] Dissolve 7 grams each of organosilicon and epoxy resin with a weight ratio of 1:1 in 10 milliliters of xylene and cyclohexanone solvents of equal volume, stir with electromagnetic force, the temperature is 50 ° C, and the stirring time is 4 Then the above solution was mixed and added to a 100 ml three-neck round bottom flask, stirred by electromagnetic force, and then 0.01 moles of dibutyltin dilaurate catalyst was gradually added dropwise with a separatory funnel as the temperature changed, and the final temperature was controlled at 136°C , reacted for 10 hours, after the reflux reaction was completed, a light yellow transparent solution was obtained, and then the solvent was removed by distillation under reduced pressure to obtain a silicone-modified epoxy resin matrix glue material, which was in the form of a viscous light yellow transparent colloid mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com