Method for Eliminating Chromatic Aberration Defects on Surface of Non-oriented Electrical Steel Sheet Coil

A technology of oriented electrical steel sheets and oriented electrical steels, which is applied to workpiece surface treatment equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as not considering the particularity of thin slab continuous casting and rolling processes, and achieve the reduction of surface color difference defects , increase the viscosity and surface tension, and increase the effect of peeling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through comparative examples and examples.

[0022] The method for eliminating chromatic aberration defects on the surface of non-oriented electrical steel sheet coils provided by various embodiments of the present invention includes the following steps:

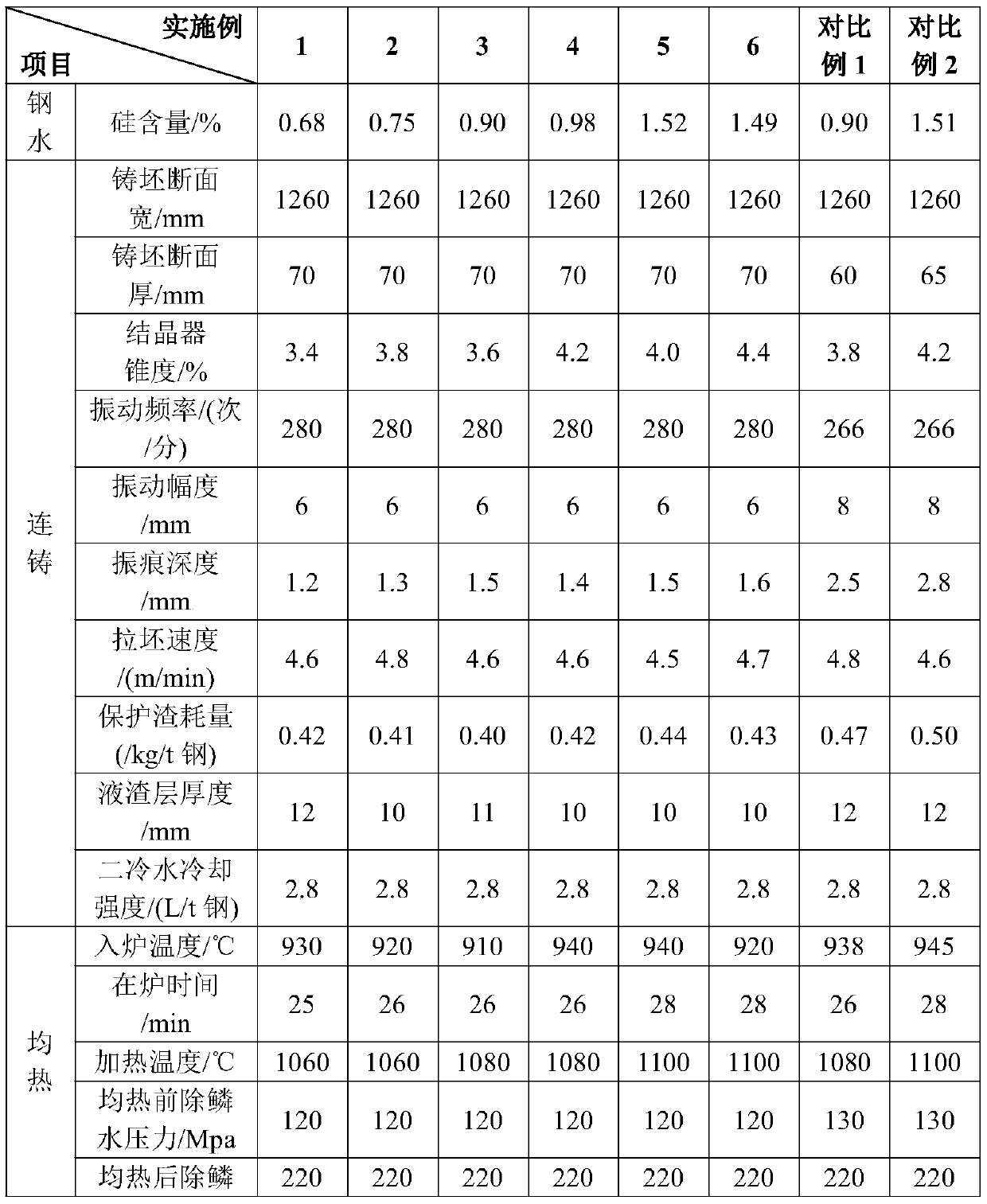

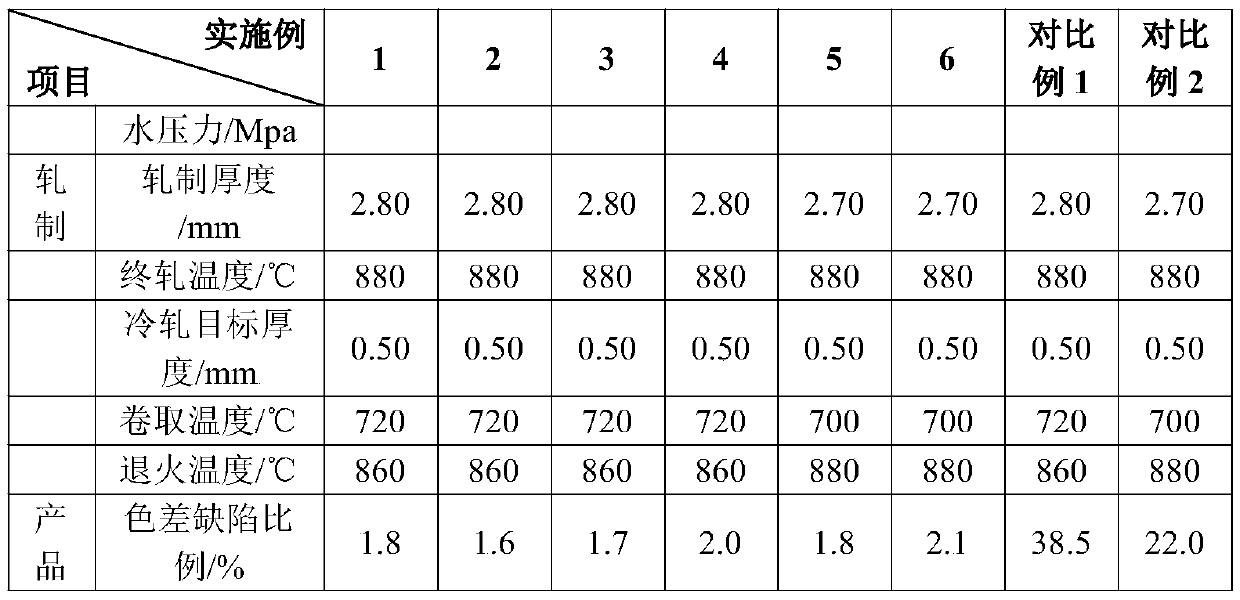

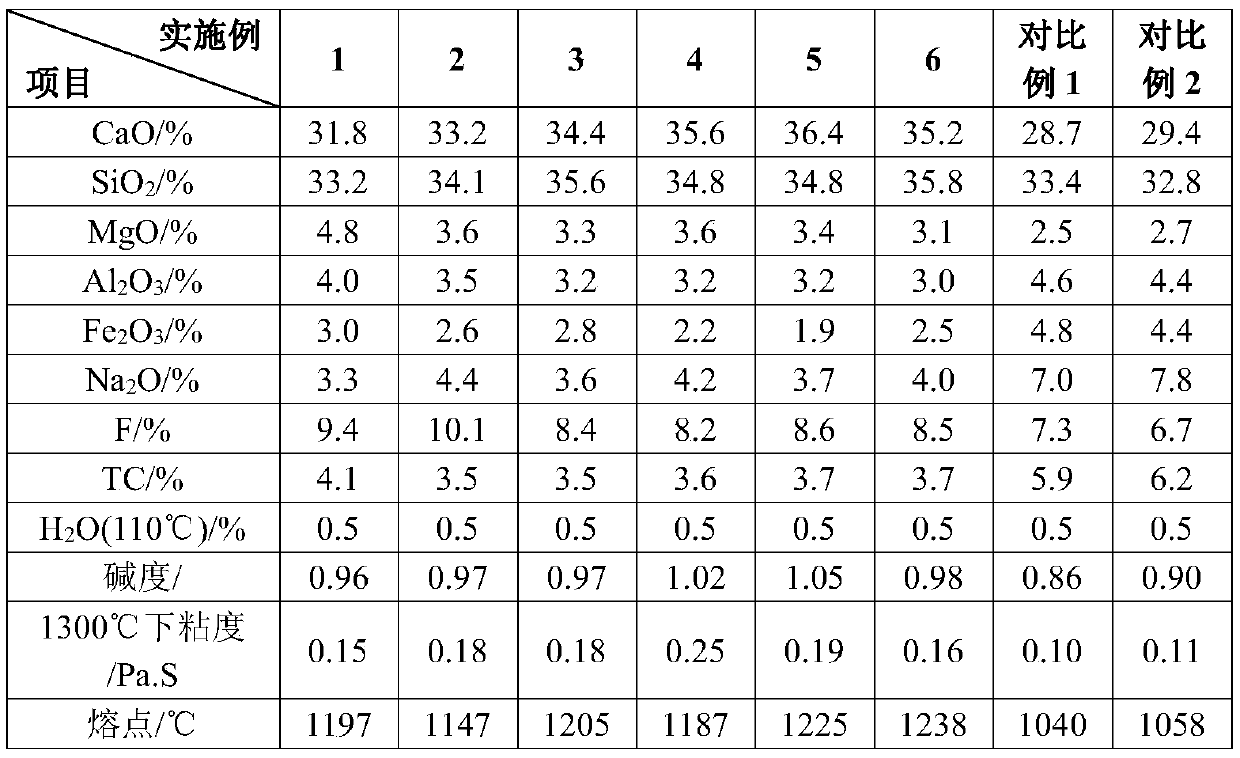

[0023] 1) Thin slab continuous casting is performed on non-oriented electrical steel molten steel with a refined silicon content of 0.5 to 2.5% (the component content is the mass content unless otherwise specified). ~90)*(900~1600)mm, mold taper is 2.5~8.0%, caster casting speed is 3.2~5.5m / min. The electromagnetic brake of the crystallizer is put into use, and the crystallizer adopts sinusoidal vibration mode. The crystallizer vibration frequency is 270-297 times / min, the vibration amplitude is ≤6mm, and the vibration mark depth of the continuous casting slab is ≤2.0mm. The consumption of mold slag is 0.30~0.60kg / t steel, the thickness of the liquid sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com