Three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

A three-dimensional silicon carbide and silicon carbide fiber technology is applied in the field of three-dimensional silicon carbide fiber reinforced silicon oxide-zirconia composite ceramic composite materials and its preparation, which can solve the problem of less gaseous raw materials and no three-dimensional silicon carbide fiber preforms. The research reports of silicon-zirconia composite ceramic composites, and the problems of unsatisfactory deposition characteristics, etc., can improve the filling degree, improve the ability of the substrate to bear and transmit loads, and improve the impregnation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

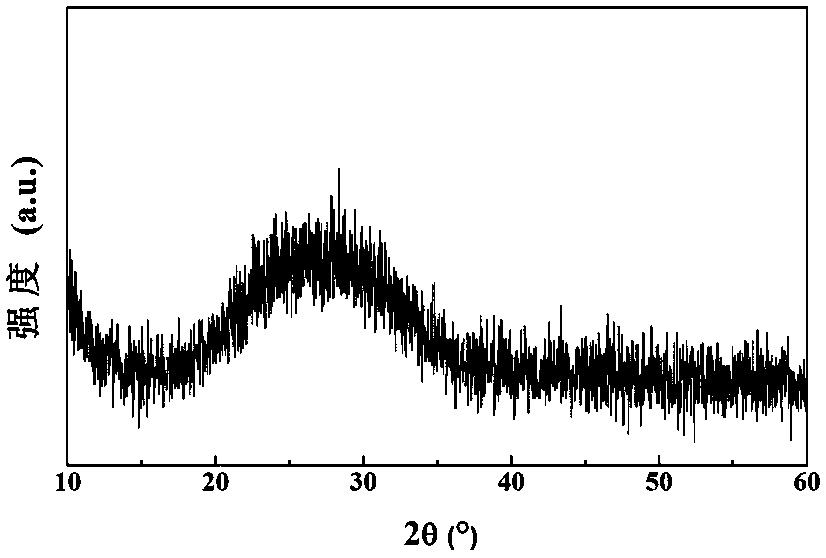

Image

Examples

Embodiment 1

[0042] A method for preparing a three-dimensional silicon carbide fiber-reinforced silica-zirconia composite ceramic composite material of the present invention comprises the following specific process steps:

[0043] (1) Sol selection: select SiO with a solid phase content of 40wt% 2 -ZrO 2 Composite sol as SiO 2 -ZrO 2 The raw material of multiphase ceramic matrix, in which SiO 2 with ZrO 2 The molar ratio is 1:1, in the above SiO 2 -ZrO 2 Add HNO to composite sol 3 As a stabilizer, HNO 3 The amount added is SiO 2 30% of the weight of the sol.

[0044] (2) Pretreatment of prefabricated parts: The three-dimensional silicon carbide fiber prefabricated part obtained by alternate lamination of silicon carbide fiber cloth and mesh tire was selected as the reinforcement phase, and the volume fraction of fibers in the three-dimensional silicon carbide fiber prefabricated part was 24%. Place the selected three-dimensional silicon carbide fiber preform under vacuum, raise t...

Embodiment 2

[0053] A method for preparing a three-dimensional silicon carbide fiber-reinforced silica-zirconia composite ceramic composite material of the present invention comprises the following specific process steps:

[0054] (1) Sol selection: select SiO with a solid phase content of 30wt% 2 -ZrO 2 Composite sol as SiO 2 -ZrO 2 The raw material of multiphase ceramic matrix, in which SiO 2 with ZrO 2 The molar ratio is 95:5, in the above SiO 2 -ZrO 2 Add HNO to composite sol 3 As a stabilizer, HNO 3 The addition amount is SiO 2 25% of the weight of the sol.

[0055] (2) Pretreatment of prefabricated parts: The three-dimensional silicon carbide fiber prefabricated part obtained by laminating and suturing silicon carbide fiber cloth is selected as the reinforcement phase, and the volume fraction of fibers in the three-dimensional silicon carbide fiber prefabricated part is 46%. The selected three-dimensional silicon carbide fiber preform is placed under vacuum, the temperature...

Embodiment 3

[0063] A method for preparing a three-dimensional silicon carbide fiber-reinforced silica-zirconia composite ceramic composite material of the present invention comprises the following specific process steps:

[0064] (1) Sol selection: select SiO with a solid phase content of 35wt% 2 -ZrO 2 Composite sol as SiO 2 -ZrO 2 The raw material of multiphase ceramic matrix, in which SiO 2 with ZrO 2 The molar ratio is 5:95, in the above SiO 2 -ZrO 2 Add HNO to composite sol 3 As a stabilizer, HNO 3 The amount added is SiO 2 20% of the weight of the sol.

[0065] (2) Pretreatment of the prefabricated part: the three-dimensional silicon carbide fiber prefabricated part with three-dimensional four-way weaving structure is selected as the reinforcement phase, and the volume fraction of the fiber in the three-dimensional silicon carbide fiber prefabricated part is 51%. The selected three-dimensional silicon carbide fiber preform is placed in a high-purity argon atmosphere, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com