Low-internal-stress heat-resistant ABS resin and preparation method thereof

An ABS resin and internal stress technology, applied in the field of low internal stress heat-resistant ABS resin and its preparation, can solve the problems of decreased fluidity, decreased fluidity, poor electroplating, etc., and can reduce viscosity, improve fluidity, and toughen efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

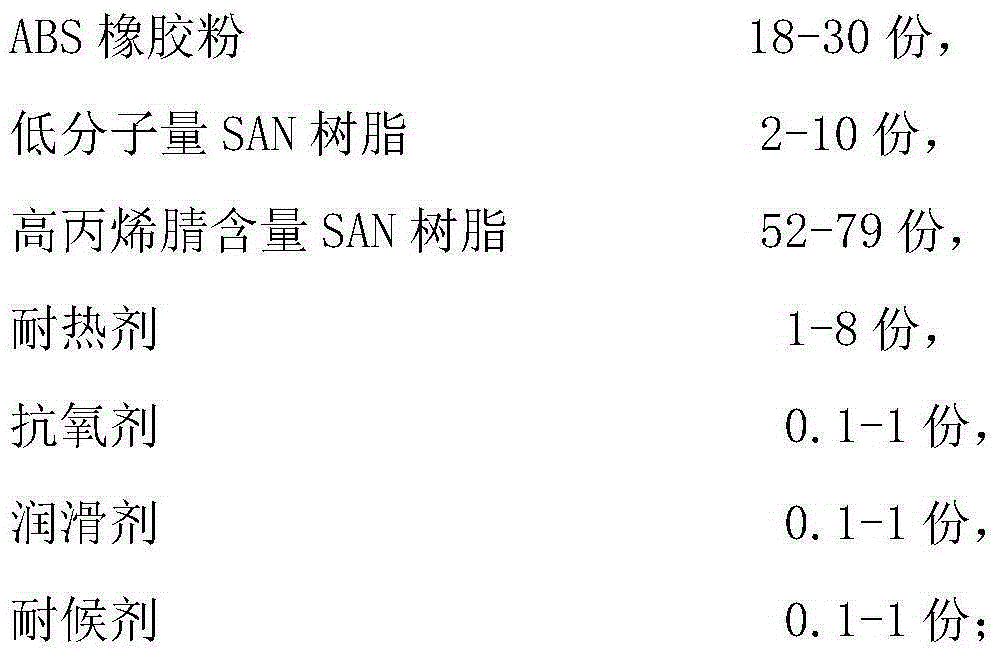

[0039] Weighing (components by weight, the same below)

[0040]

[0041] Put the above raw materials into a high-speed mixer and stir for 5-30 minutes, then discharge to obtain a mixture;

[0042] The mixture is extruded and granulated through a twin-screw extruder, wherein the temperature of the twin-screw extruder is 180-260° C., and the screw speed is 180-600 rpm. The product is obtained by conveying, melting, shearing, extrusion, cooling and granulation.

Embodiment 2

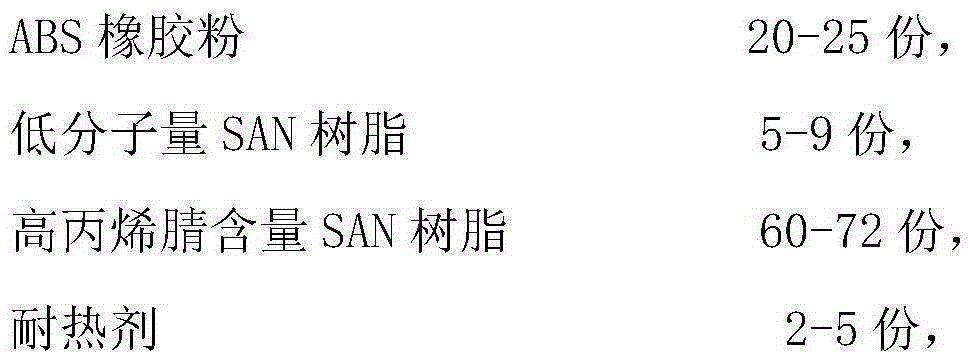

[0044] Weighing (components by weight, the same below)

[0045]

[0046]

[0047] The product is obtained by the method of Example 1.

Embodiment 3

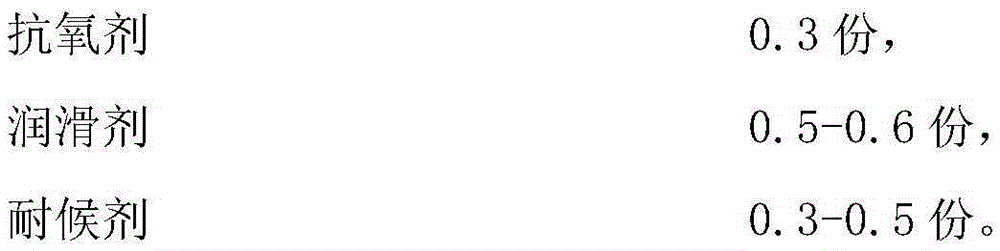

[0049] Weighing (components by weight, the same below)

[0050]

[0051] The product is obtained by the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com