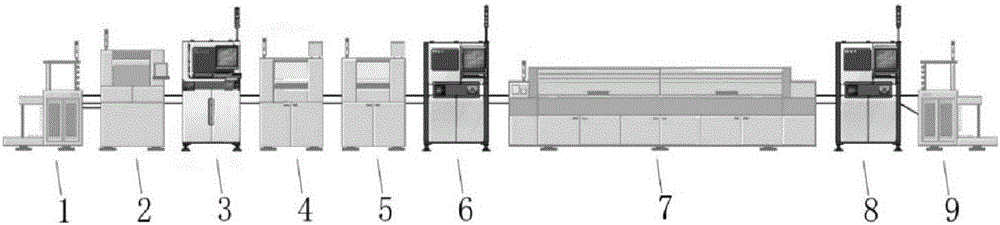

Intelligent monitoring system for quality of PCB solder paste printing process and method

An intelligent monitoring system and solder paste printing technology, which is applied in the field of surface mount and PCB solder paste printing process quality monitoring, can solve the problems that cannot be prevented, reduce solder paste printing defects, solve equipment operation islands, and improve SMT process quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

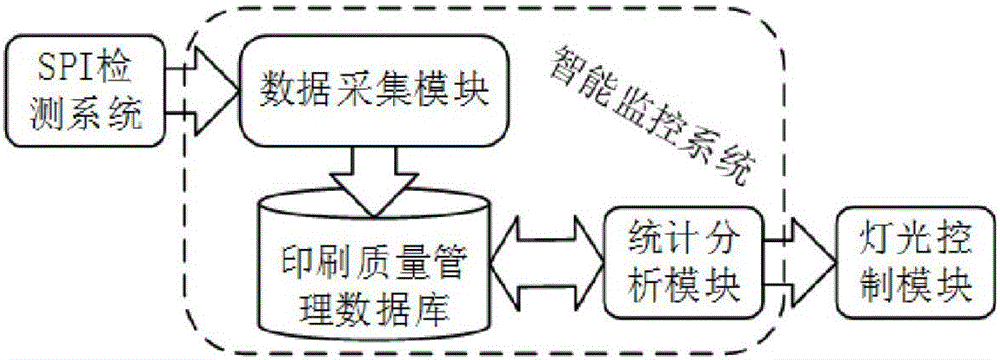

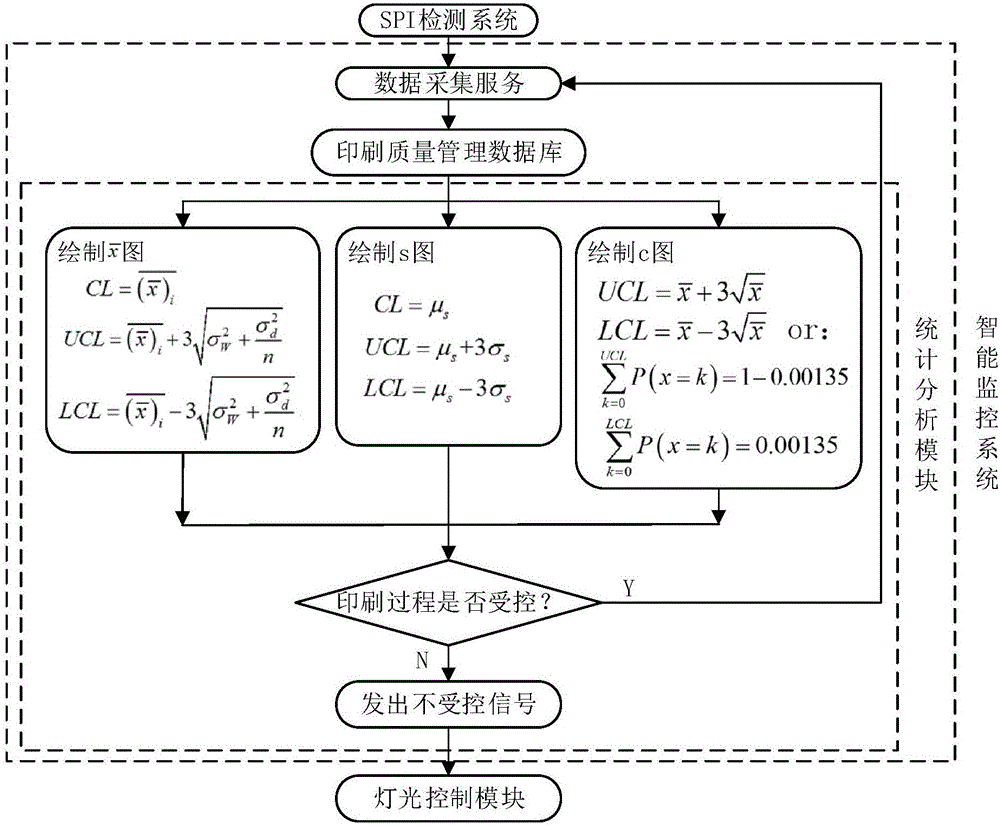

[0031] An intelligent monitoring system for PCB solder paste printing process quality, including a data acquisition module, a printing quality management database, a statistical analysis module and a lighting control module; the printing quality management database can be used to store the data of the data acquisition module and the statistical analysis module respectively, convenient Staff view call history data.

[0032] The data acquisition module is used for real-time acquisition of various parameter data in the PCB solder paste printing process detected by the SPI detection system, and simultaneously transmits the collected data to the printing quality management database for storage;

[0033] The statistical analysis module acquires the data collected by the data collection module (it can directly read the data collected by the data collection module, or read the data stored in the printing quality management database by the data collection module), and analyze the data, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com