Arrangement structure of the ink path system of a commercial rotary offset printing machine

A technology of offset printing machine and ink path, which is applied to the general parts of printing machinery, printing machines, printing, etc. It can solve the problems of ink shortage ghosting, uneven water film, unevenness, etc., to reduce printing color difference and eliminate printing Color change, uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

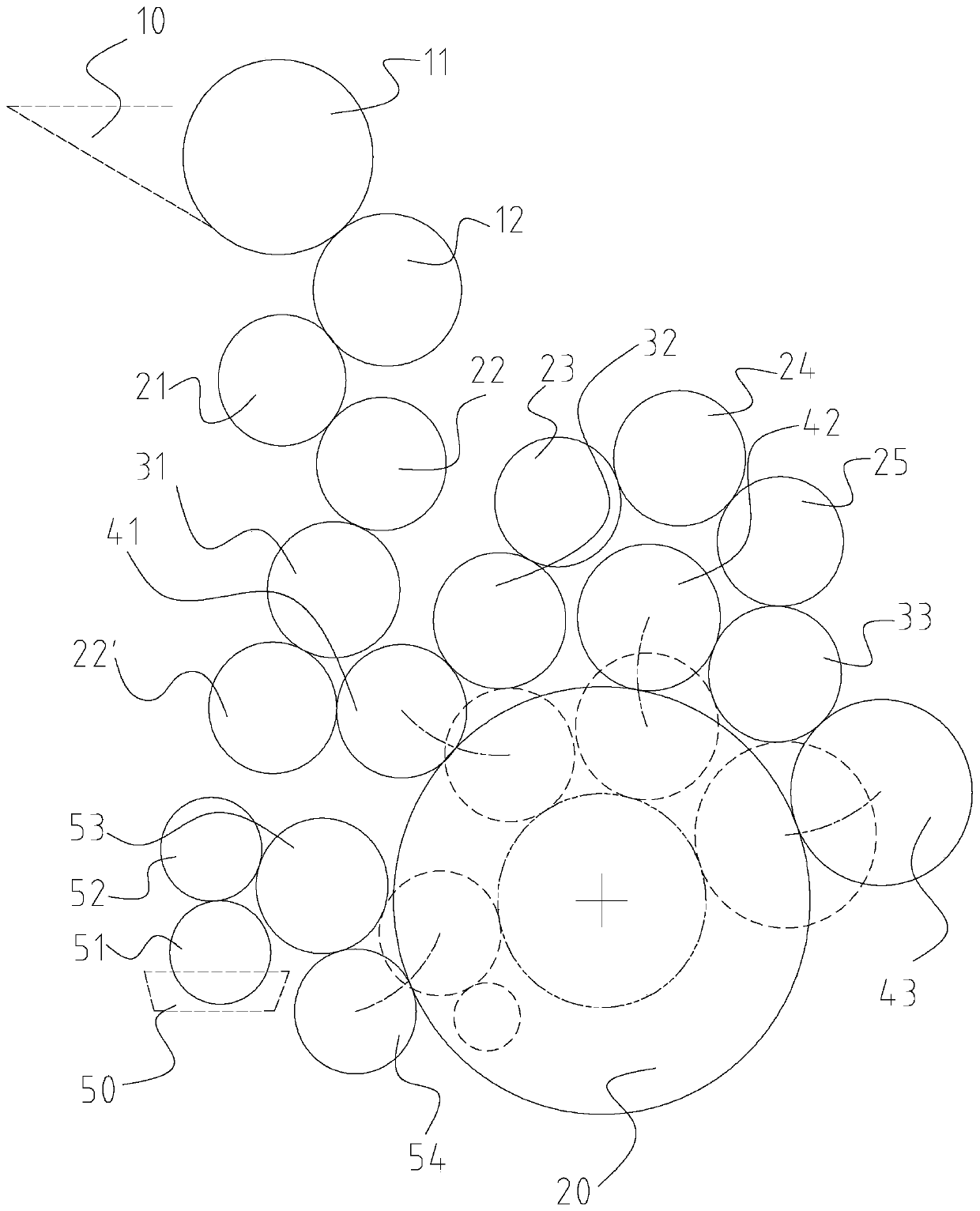

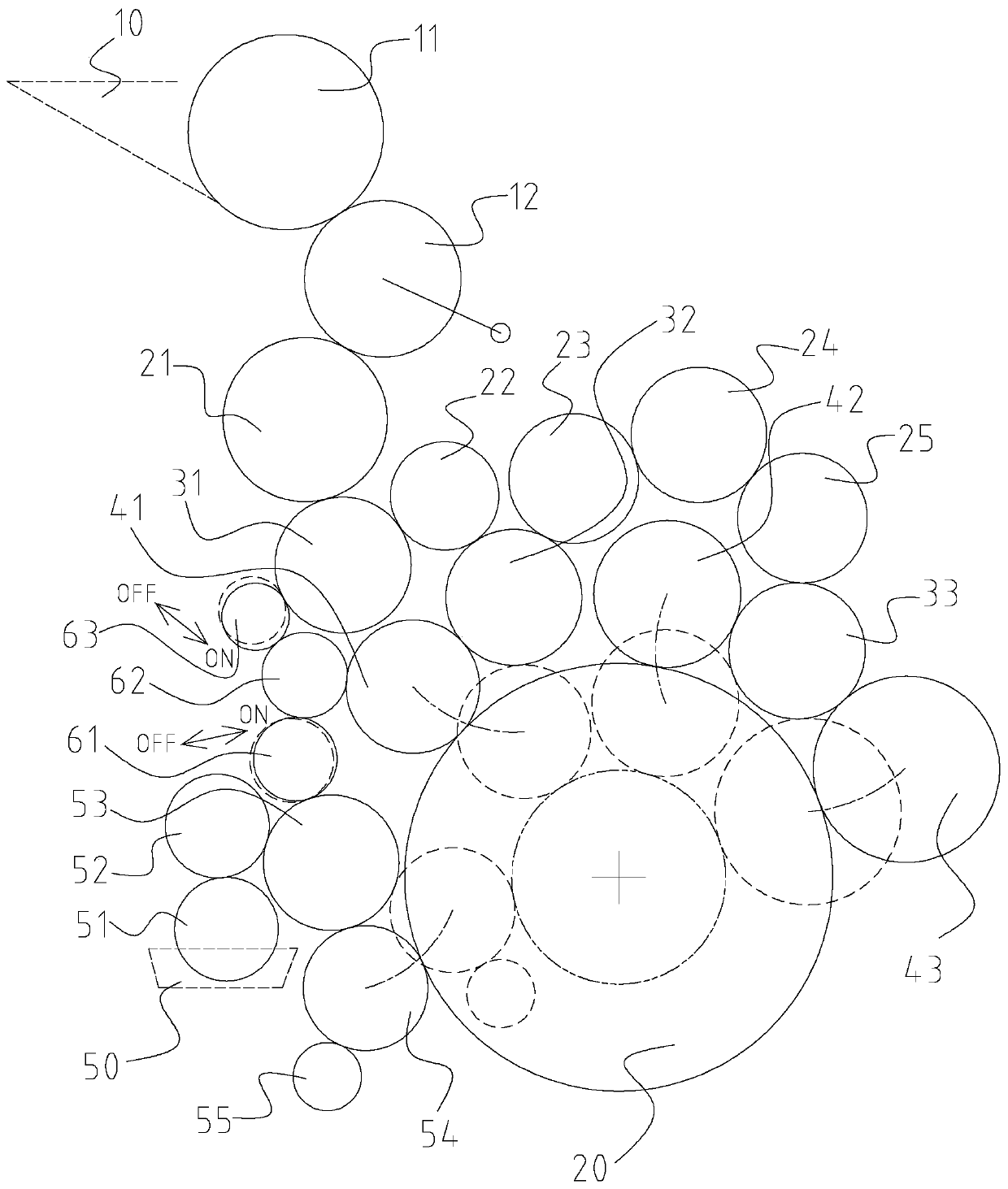

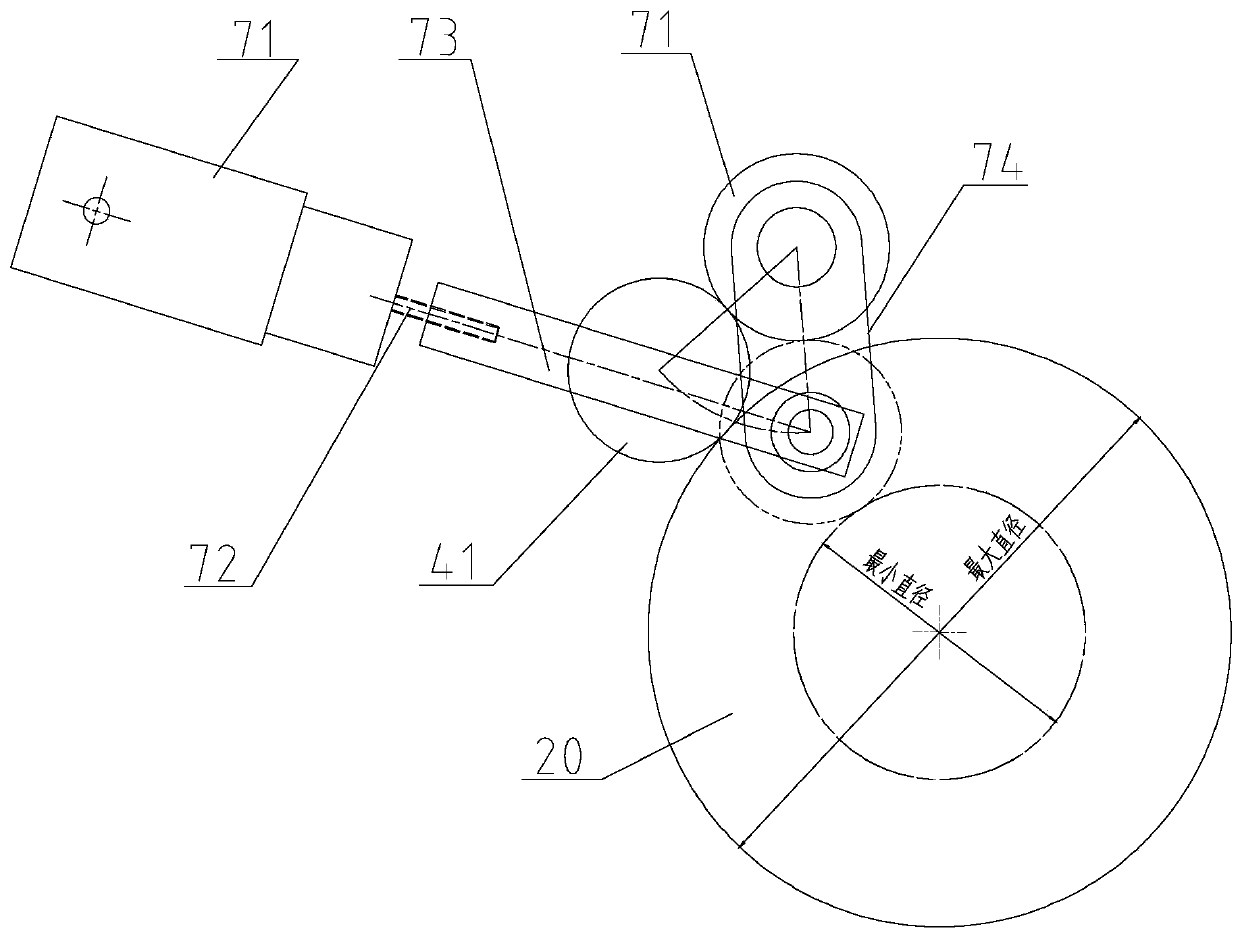

[0032] see figure 2 , the arrangement structure of the ink path system of the commercial rotary offset printing press of the present invention includes an ink delivery device, a water supply device and a connecting device.

[0033] The inking device includes an ink supply unit, an inking unit and an ink distribution unit; among them:

[0034] The ink supply part includes an ink fountain 10 filled with ink arranged on the upper left of the printing plate cylinder 20, an ink fountain roller 11 located at the right part of the ink fountain 10, and an ink transfer roller 12 contacting the lower right part of the ink fountain roller 11;

[0035] The inking part includes first to third inking rollers 41-43 contacting the upper part of the plate cylinder 20 from left to right;

[0036] The ink distribution section includes the first to fifth ink distribution rollers 21-25 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com