Split bucket tooth for buckets of excavators and manufacturing method thereof

A manufacturing method and excavator technology, applied in manufacturing tools, earth movers/shovels, coatings, etc., can solve the problems of excavator bucket teeth that are easy to break, difficult to replace, and short-lived

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

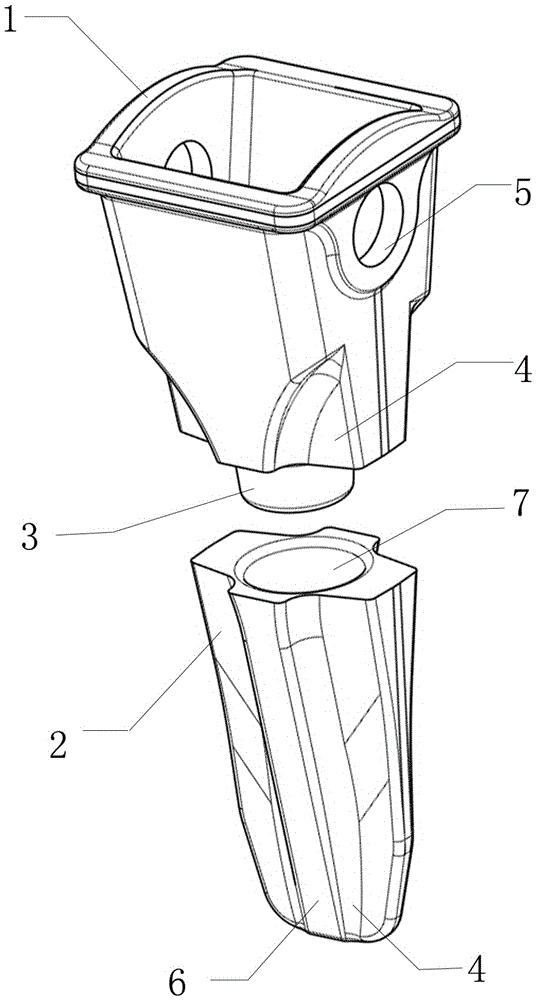

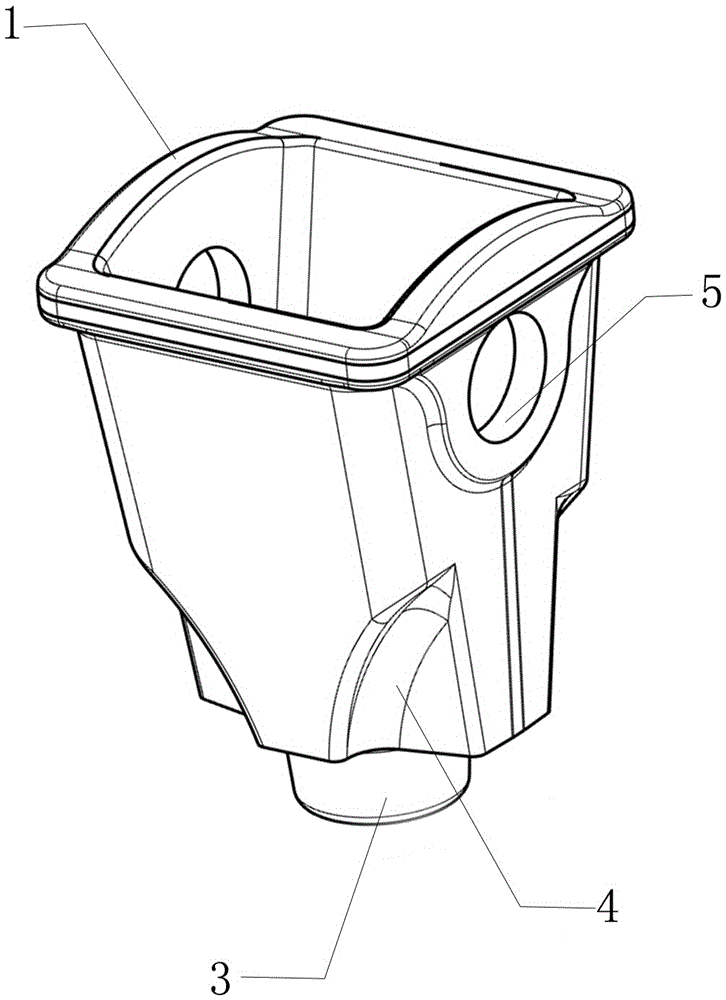

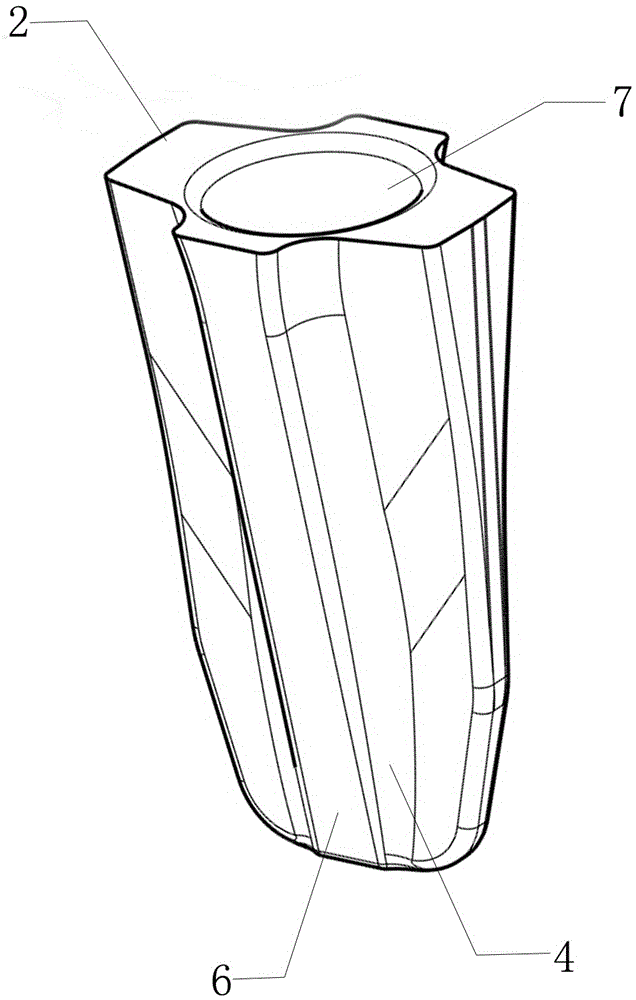

[0046] It can be seen from the content of the invention that a split bucket tooth of an excavator bucket is composed of a tooth rear 1 and a tooth tip 2; Boss 3 is set on the bottom of tooth rear 1, groove 4 is set on four corners of the lower part of tooth rear 1, mounting hole 5 is set on the upper part of tooth rear 1; tooth tip 2 is provided with groove 4, convex strip 6 and connecting Concave holes 7, wherein the grooves 4 are arranged on the four corners of the tooth tip 2, the convex strips 6 are arranged on the front and rear sides of the tooth tip 2, and the connecting concave holes 7 are arranged on the top of the tooth tip 2.

[0047] The present invention is provided with mounting hole 5 in order to facilitate bucket tooth to be installed on the excavator bucket; Mounting hole 5 is designed in tooth rear 1 top, and mounting hole 5 has two, is relative design.

[0048] In order to realize the replaceability of the tooth tip 2 and the repeated use of the tooth rear 1...

Embodiment 2

[0079]It can be seen from the content of the invention and the accompanying drawings that an excavator bucket has a split tooth, which is composed of a rear tooth 1 and a tooth tip 2. It is assembled together; and a circular taper connection boss 3 is provided on the back of the tooth 1, and a circular taper connection concave hole 7 is provided on the tooth tip 2; the circular taper connection boss 3 and the circular taper connection concave hole 7. The protrusions and recesses must correspond in reverse to play the role of connecting parts; the shapes of the protrusions and recesses must be the same, and the cross-sectional size is determined according to the calculation of the force of the bucket teeth. The dimensional tolerance is based on The connection method is determined; the connection methods include press fit under normal temperature with interference, press fit under medium temperature with interference, press fit under high temperature with interference (referred t...

Embodiment 3

[0095] From the content of the invention and the attached Image 6 , 7 It can be known that an excavator bucket split tooth is composed of the tooth rear 1 and the tooth tip 2, the tooth rear 1 and the tooth tip 2 are connected by a diamond-shaped taper, and the interference fit is assembled at room temperature; The back of the tooth 1 is provided with a diamond-shaped taper connection boss 3, and the tooth tip 2 is provided with a diamond-shaped taper connection concave hole 7; the protrusions and recesses of the diamond-shaped taper connection boss 3 and the diamond-shaped taper connection concave hole 7 must correspond in reverse , to play the role of the connecting part; the shape of the protruding and concave parts must be the same, the cross-sectional size is determined according to the calculation of the force of the bucket teeth, and the dimensional tolerance is determined according to the connection method; the connection method has interference Press fit at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com