Polymorphic nitro-compound fertilizer and production method thereof

A nitro compound fertilizer and multi-morphic technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve problems such as backward production facilities and management measures, secondary salinization of soil, and decline in crop quality, and achieve the goal of preventing and controlling mold The effects of survival and reproduction, promotion of crop growth, and scientific proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

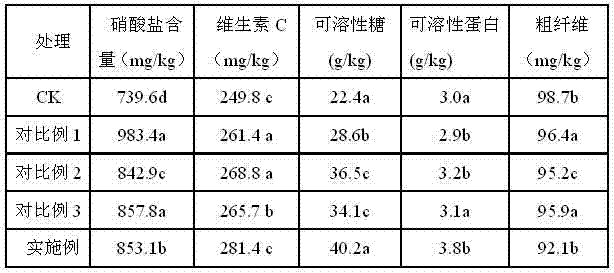

Examples

Embodiment

[0051] Example :Preparation of multi-form nitro compound fertilizer (22-10-10)

[0052] The raw material components are as follows:

[0053] 100 parts of urea,

[0054] 425 parts of ammonium nitrate,

[0055] 98 parts of ammonium sulfate,

[0056] 200 parts of potassium sulfate,

[0057] 175 parts of monoammonium phosphate,

[0058] 2 parts of medium and micro-fertilizer;

[0059] Among them, the nitrogen content in monoammonium phosphate is 10%, and the phosphorus pentoxide content is 50%.

[0060] production method:

[0061] (1) Mix urea and ammonium nitrate phosphorus at the bottom of the tower, add them to the ammonium nitrate melter after mixing, melt at a high temperature of 140°C, the molten slurry enters the buffer tank, pressurize by the transfer pump, and send it to In the first-level mixing tank at the top of the tower;

[0062] (2) Put potassium sulfate, ammonium sulfate, and medium and micro-fertilizer into a mixer for thorough mixing. After crushing and sieving, the mixed raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com