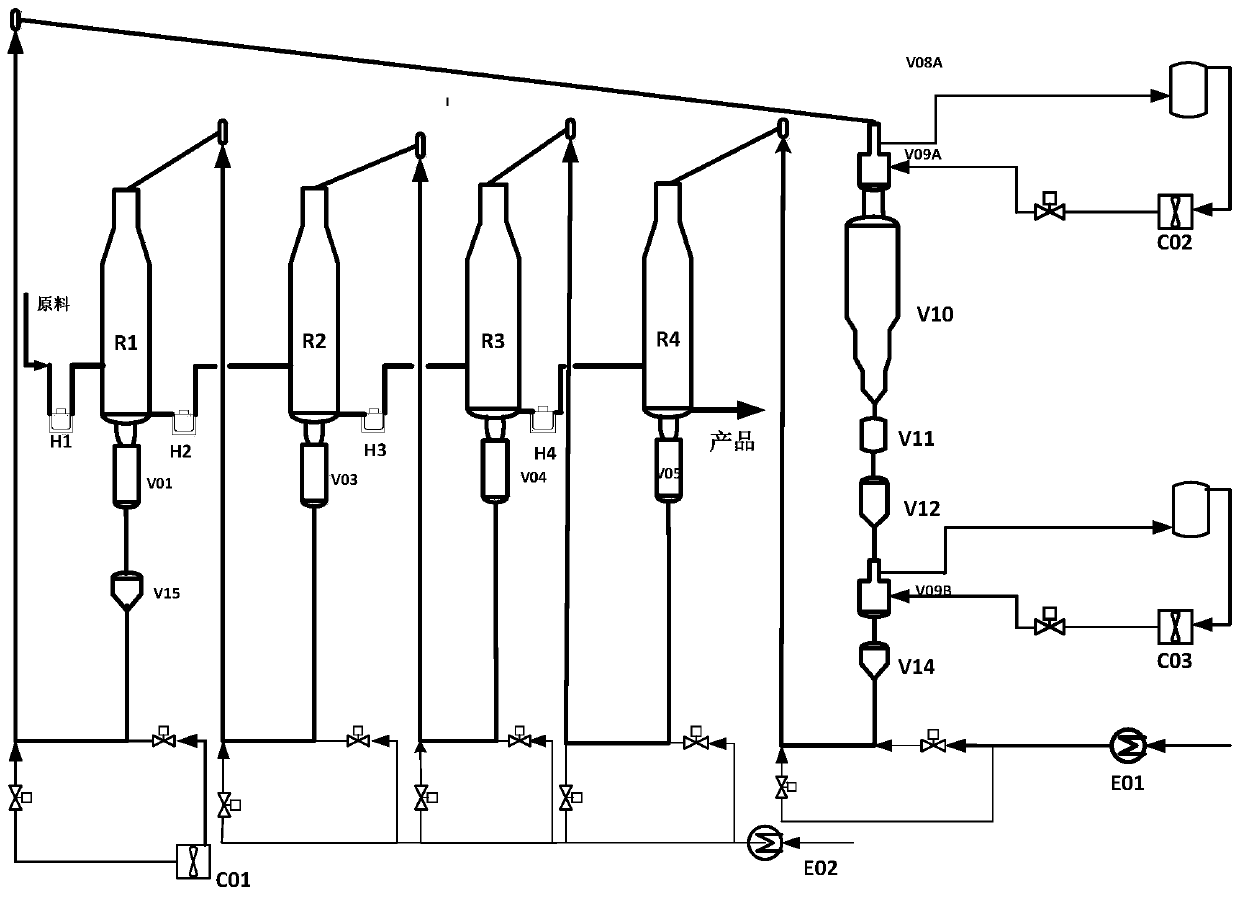

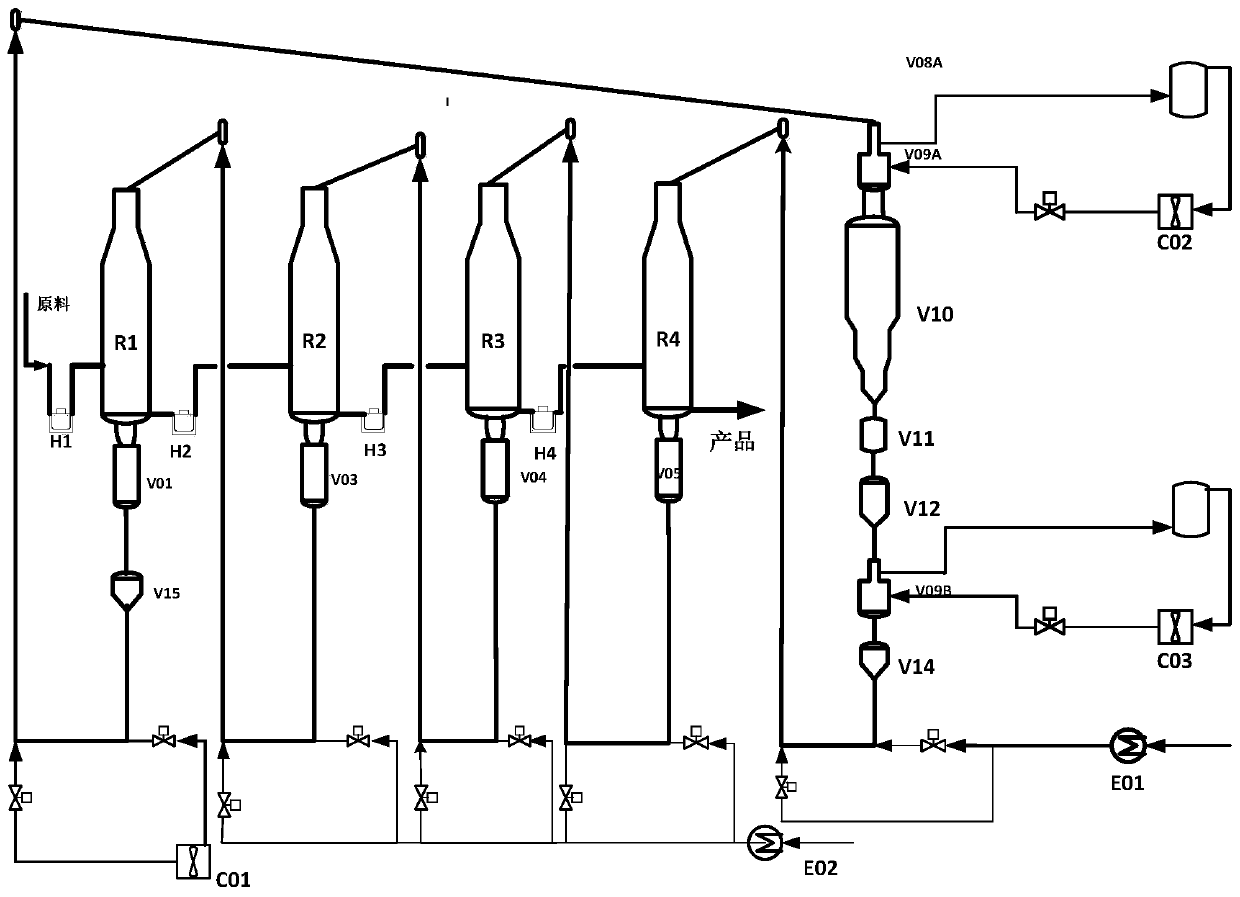

Process for preparing propylene through combined reaction feeding and catalyst regeneration countercurrent contact dehydrogenation

A catalytic dehydrogenation and countercurrent contact technology, which is applied in catalyst regeneration/reactivation, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of easy blockage of terminal reactors, short operation cycle of UOP process, and influence on operation cycle, etc. Achieve the effect of reducing catalyst dust, reducing the risk of clogging and long operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Propane / H 2 According to 100:50mol mixed according to 15Nm 3 / h enters the reactor and is heated to 625°C by the heating furnace H1, then enters the first reactor R1, then is heated to 625°C by the heating furnace H2, enters the second reactor R2, and then is heated to 625°C by the heating furnace H3 and enters The third reactor R3 is finally heated to 625°C by the heating furnace H4 and enters the fourth reactor R4, which runs continuously on-line for 3 hours. The reacted product (propylene) enters the subsequent separation system for separation, and the analysis can obtain a yield of up to 33.6% propylene;

[0035] Catalyst cycle regeneration: the process gas is carried out in the direction from R1-R2-R3-R4, the direction of catalyst and process gas feed is just opposite, and the phase countercurrent reaction, process gas flows from the direction of reactor R1-R2-R3-R4, The catalyst flows in the direction of reactor R4-R3-R2-R1.

[0036] During the catalyst cycle re...

Embodiment 2

[0039] Propane / H 2 According to 100:50mol mixed according to 15Nm 3 / h enters the reactor and is heated to 615°C by the heating furnace H1, then enters the first reactor R1, then is heated to 615°C by the heating furnace H2, enters the second reactor R2, and then is heated to 615°C by the heating furnace H3 to enter The third reactor R3 is finally heated to 615°C by the heating furnace H4 and enters the fourth reactor R4, which runs continuously on-line for 3 hours. The reacted product (propylene) enters the subsequent separation system for separation, and the analysis can obtain a yield of up to 31.2% propylene;

[0040] Catalyst cycle regeneration: the process gas is carried out in the direction from R1-R2-R3-R4, the direction of catalyst and process gas feed is just opposite, and the phase countercurrent reaction, process gas flows from the direction of reactor R1-R2-R3-R4, The catalyst flows in the direction of reactor R4-R3-R2-R1.

[0041] During the catalyst cycle reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com