Woodworking cutting tool machining method

A processing method and tool technology, applied in the field of tool processing, can solve the problems of shortening the service life of the tool, welding cracks of the blade, cutting force on the cutting edge of the tool and uneven chip removal, etc., and achieve the effect of ensuring safe use and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

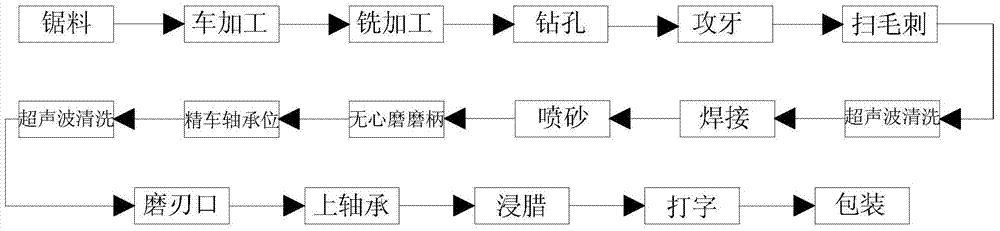

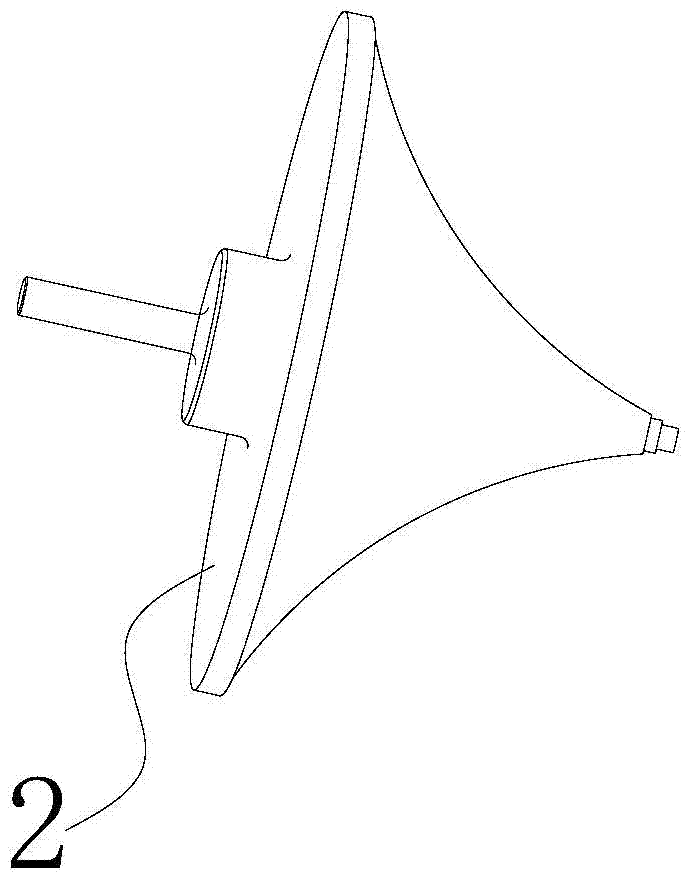

[0030] refer to figure 1 Shown, a kind of processing method of woodworking cutter of the present invention comprises the following steps:

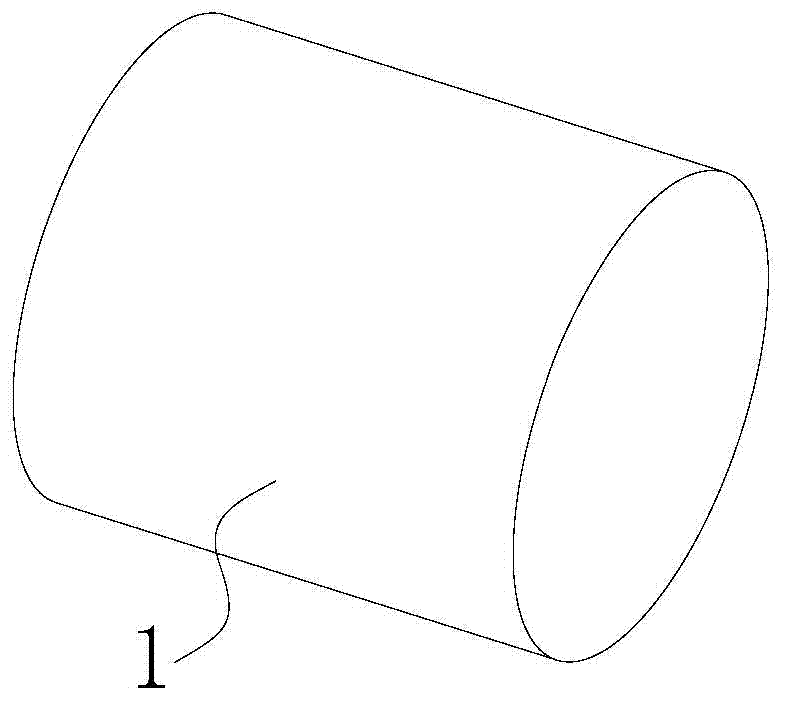

[0031] (1) Bar sawing material: According to the outer diameter of the cutter body and the length of the cutter body, select a suitable round bar to process into a blank, so as to ensure the internal quality of the material.

[0032] (2) Turning: According to the process requirements, the excess bar is turned by turning to form the rough blank of the tool.

[0033] (3) Milling: use a milling machine to finish the rough blank of the tool.

[0034] (4) Drilling: Drill holes according to process requirements.

[0035] (5) Tapping: Process the internal thread at the position of the hole, which is used to fasten the hexagon socket he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com