Preparation method of composite fruity tobacco essence

A technology for tobacco flavor and fruit flavor, which is applied in the preparation of tobacco, essential oils/spice, tobacco, etc., can solve the problems of thin flavor, not mellow and single fruit flavor, etc., and achieves soft and delicate smoke, rich aroma layers, craftsmanship and so on. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

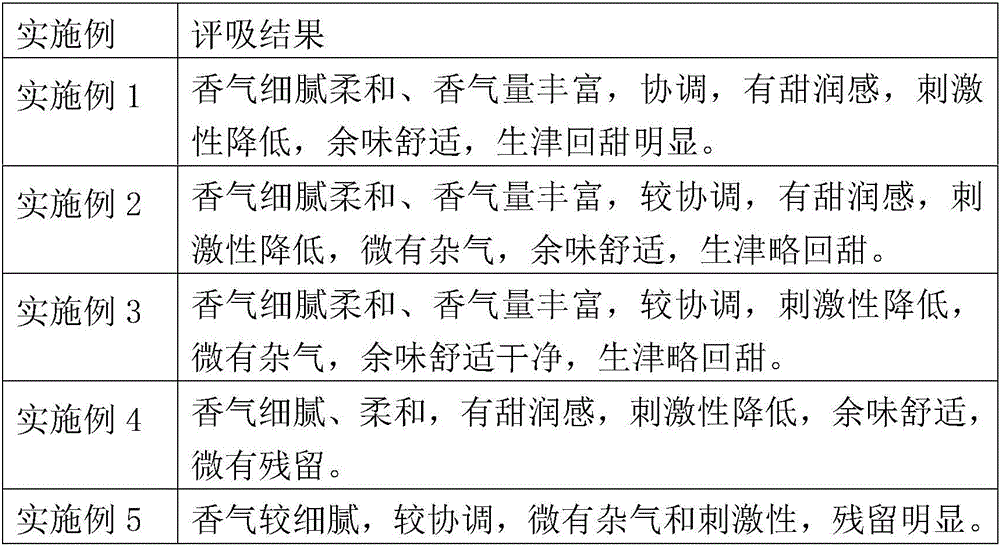

Examples

Embodiment 1

[0010] Example 1: 25g of apple peel, 110g of grape peel, 95g of watermelon peel, 16g of orange peel, 60g of banana peel, 8g of mango peel, and 30g of pomelo peel are respectively crushed into slag and mixed, adding compound enzyme and 900g of water, and adjusting the pH to 5.2 , the temperature is 46°C, after enzymolysis for 50min, the temperature is raised to 100°C and kept for 10min to inactivate the enzyme, then add 1.5g sodium benzoate, 0.4g titanium dioxide, 9.2g riboflavin, 2g adipic acid, 20g sodium sulfate, 23ml With n-butanol, continue to decoct at 100°C for 1.5h, filter, and concentrate the filtrate to a relative density of 1.08.

[0011] The compound enzyme described therein includes pectinase and cellulase, the consumption of pectinase is 4000U / g banana peel, and the consumption of cellulase is 200U / g grape skin.

Embodiment 2

[0012] Example 2: 20g of apple peel, 100g of grape peel, 80g of watermelon peel, 12g of orange peel, 50g of banana peel, 5g of mango peel, and 20g of pomelo peel are respectively crushed into slag and mixed, adding compound enzyme and 800g of water, and adjusting the pH to 5.0 , the temperature is 45°C, after enzymolysis for 40min, the temperature is raised to 100°C and kept for 10min to inactivate the enzyme, then add 1.2g sodium benzoate, 0.2g titanium dioxide, 8.5g riboflavin, 1g adipic acid, 15g sodium sulfate, 20ml With n-butanol, continue to decoct at 100°C for 1.5h, filter, and concentrate the filtrate to a relative density of 1.02.

[0013] The compound enzyme described therein includes pectinase and cellulase, the consumption of pectinase is 4000U / g banana peel, and the consumption of cellulase is 200U / g grape skin.

Embodiment 3

[0014] Example 3: 30g of apple peel, 120g of grape peel, 110g of watermelon peel, 20g of orange peel, 70g of banana peel, 10g of mango peel, and 40g of pomelo peel are respectively crushed into slag and mixed, then compound enzyme and 1000g of water are added to adjust the pH to 5.3 , the temperature is 50°C, after enzymolysis for 60min, the temperature is raised to 100°C and kept for 10min to inactivate the enzyme, then add 1.8g sodium benzoate, 0.6g titanium dioxide, 11.2g riboflavin, 3g adipic acid, 23g sodium sulfate, 25ml With n-butanol, continue to decoct at 100°C for 2 hours, filter, and concentrate the filtrate to a relative density of 1.12.

[0015] The compound enzyme described therein includes pectinase and cellulase, the consumption of pectinase is 4000U / g banana peel, and the consumption of cellulase is 200U / g grape skin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com