Release paper emptying device in multilayer adhesive tape production line

A discharge device and production line technology, which can be applied to other household appliances, etc., can solve the problems of discontinuous feeding of release paper, affecting the continuous production of the production line, and stoppage of the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

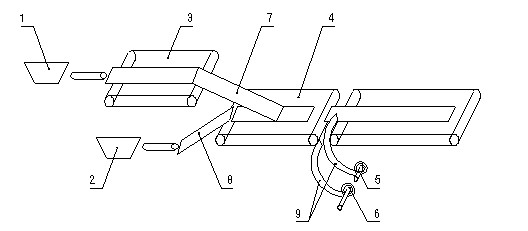

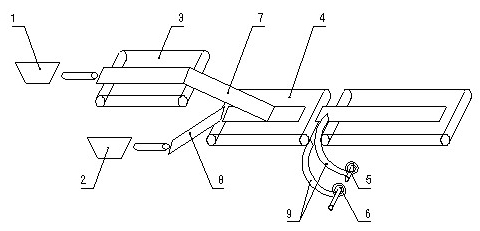

[0011] Such as figure 1 As shown, the release paper discharging device in the multi-layer rubber strip production line of the present invention comprises a production line support and a synthetic conveyor belt 4 arranged on the production line support, and the production line support is provided with a pair of release paper below the synthetic conveyor belt 4. Model paper feeding frame 5 and 6.

[0012] The production process of the multi-layer rubber strip production line equipped with the above-mentioned discharging device is as follows: the foam layer 7 formed after being extruded by the extruder 1 travels along the guide conveyor belt 3, and after being extruded by the extruder 2 The bonding layer 8 that forms synthesizes anti-vibration rubber strip on synthetic conveyer belt 4, then, sticks the release paper 9 dropped on the release pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com